Sludge drying processing method and equipment

A sludge drying and treatment method technology, which is applied in the directions of oxidation treatment sludge, dehydration/drying/concentrated sludge treatment, by-product vaporization, etc., can solve the problem of low output of belt dryer, low sludge drying rate, moisture Difficult to transfer and other problems, to achieve the effect of promoting the industrialization process, fast heating speed, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

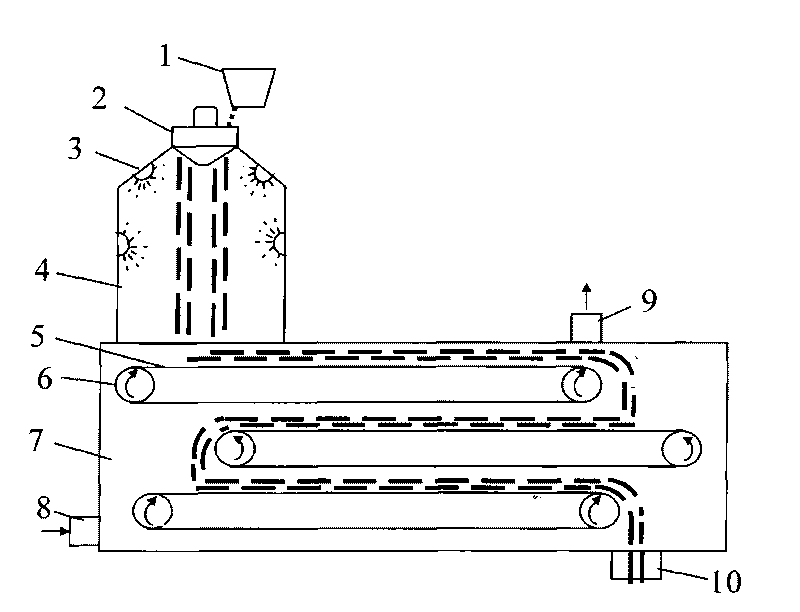

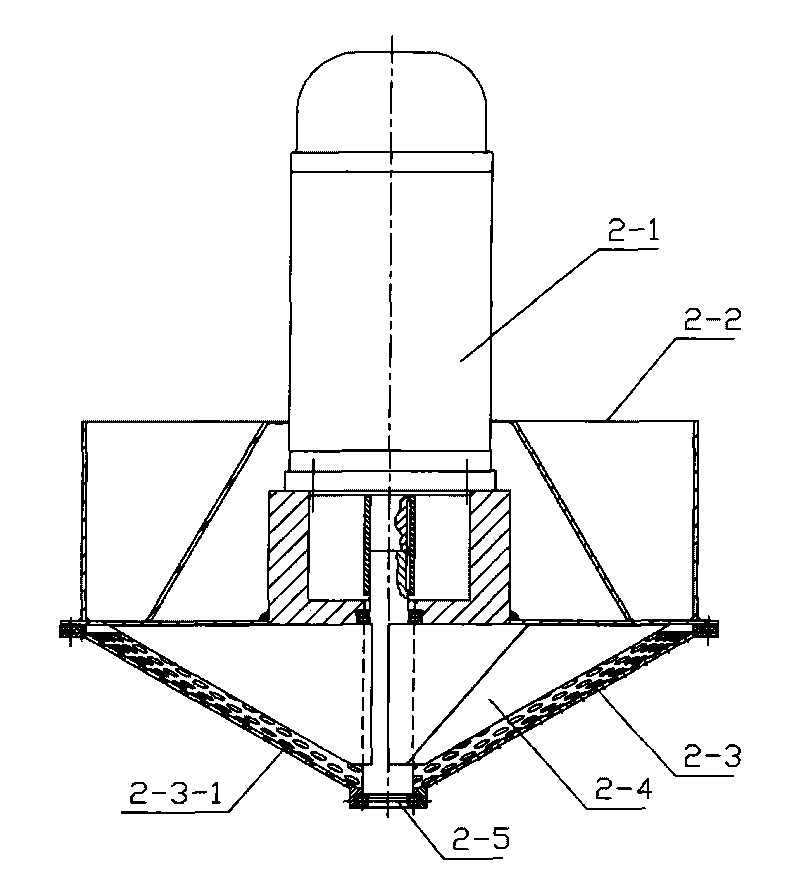

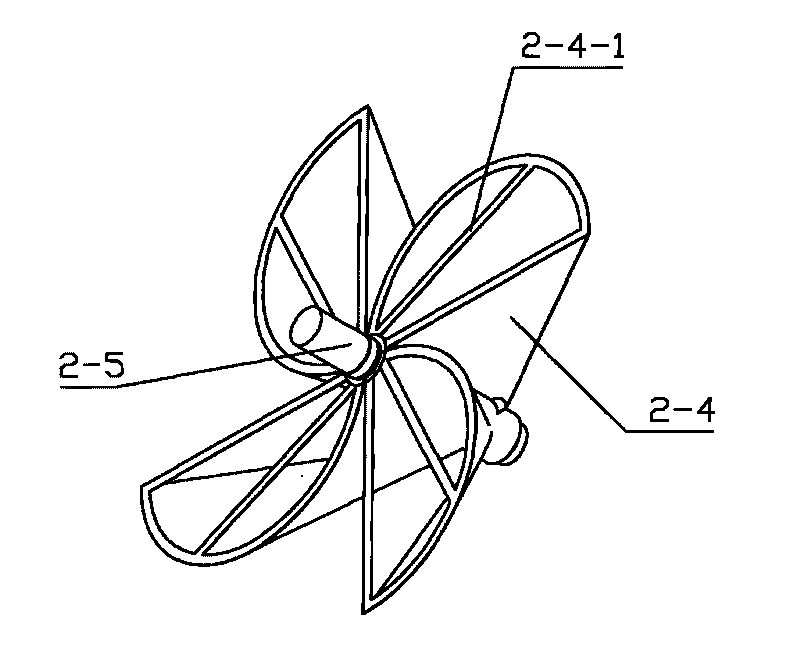

[0021] see figure 1 , the present invention is a sludge drying treatment method. The specific process is to firstly mix the sludge after press filtration in a sewage plant with a small amount of combustible powder. The combustible powder is sawdust, coal powder, coal gangue powder and straw powder. Any one, its mass ratio to the sludge is 1:20~1:5, after mixing, the sludge is extruded into a mud string with a diameter of 3~10mm by a mud stringer, and the mud string is in the process of falling, using far-infrared The lamp is irradiated without shadow, and the outer surface of the mud string is quickly dried under the powerful heat radiation of the infrared lamp and forms a layer of soft shell. The sludge string with soft shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com