Waste incineration fly ash sintering reduction treatment technique

A technology of waste incineration fly ash and technology, which is applied in the field of waste incineration fly ash sintering reduction treatment, can solve the problems of high heavy metal content in fly ash sintering and potential hazards in resource utilization, and achieves low long-term potential impact and recycling. The effect of improved utilization efficiency, lower energy consumption and lower treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

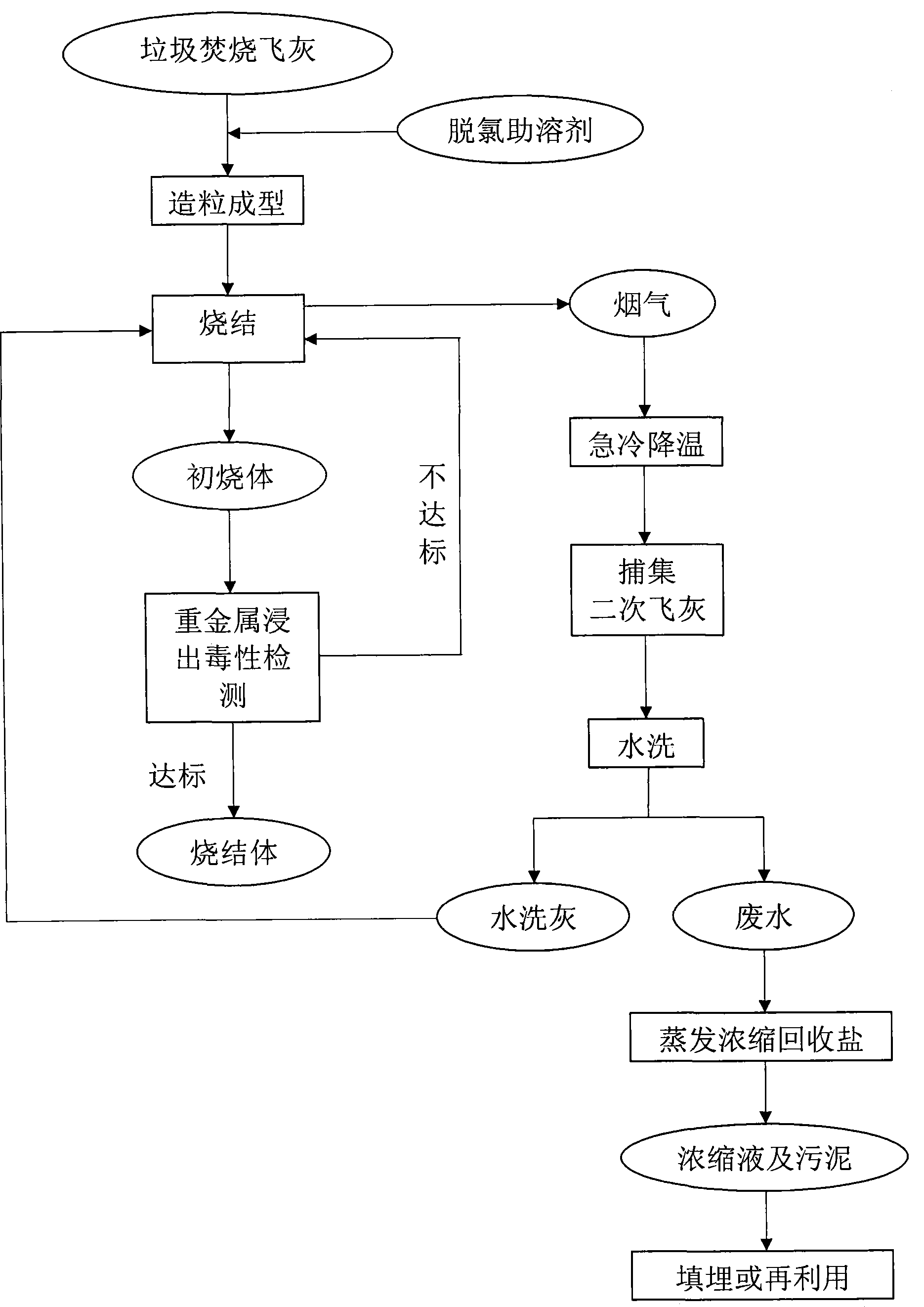

Method used

Image

Examples

Embodiment 1

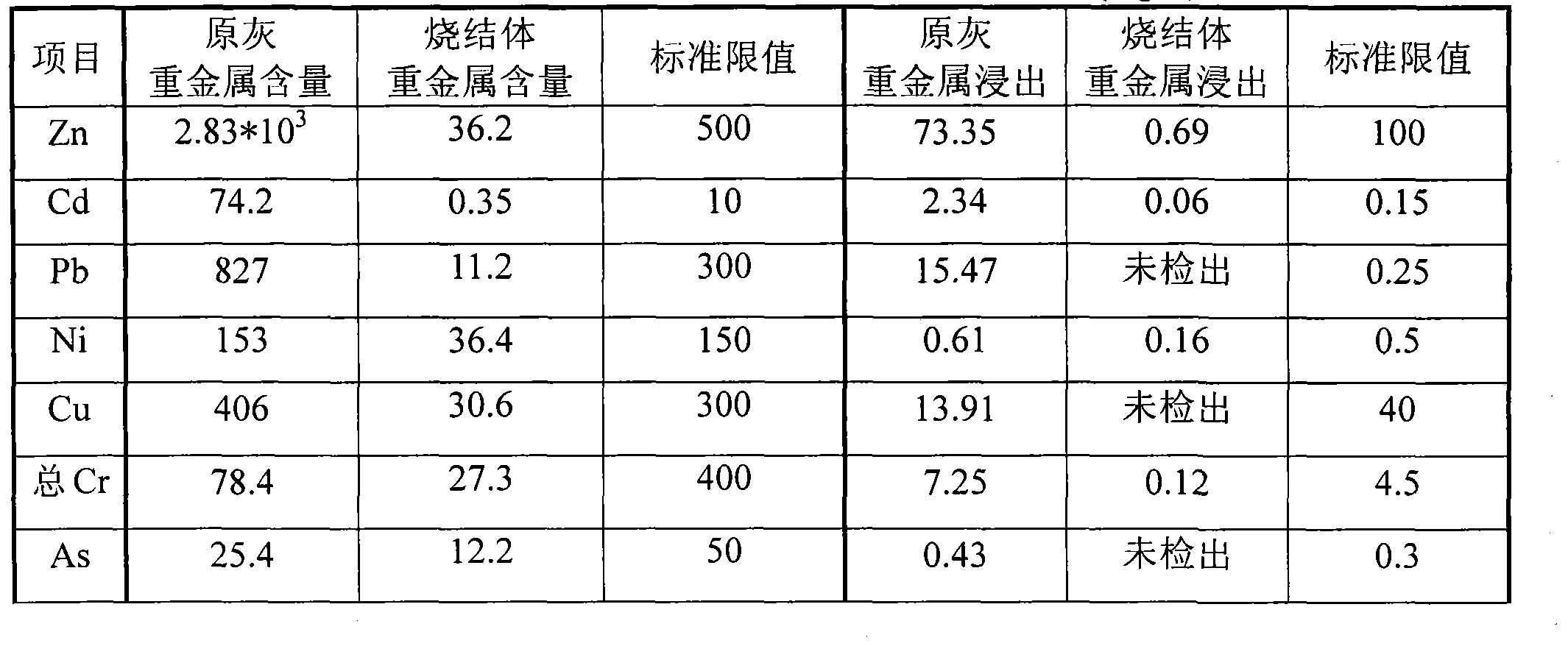

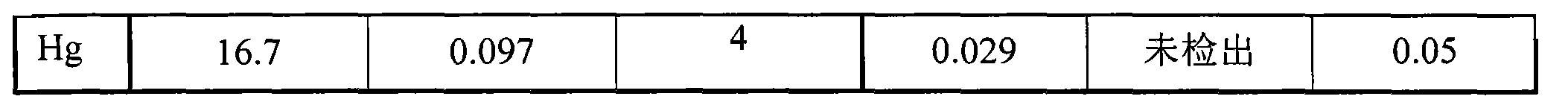

[0023] (1) Get 1 ton of waste incineration fly ash, measure the total salt content of waste incineration fly ash to be 18.8%, mix the three according to the mass ratio of waste incineration fly ash: dechlorination co-solvent: water=88: 2: 10 Uniform, granulated and shaped, the green body has a diameter of 10mm and a length of 10mm, and the dechlorination co-solvent is activated alumina and sodium carbonate;

[0024] (2) The sintered green body is sintered at 550°C for 28 minutes, and the flue gas generated by sintering is rapidly cooled to lower the temperature of the flue gas to below 200°C, and then collected twice by an electrostatic collector Fly ash, the secondary fly ash is 5.6% (dry weight) of the original ash;

[0025] (3) The collected secondary fly ash is stirred with leachate and washed with water. The washed fly ash is 15.2% (dry weight) of the secondary fly ash. The waste heat is evaporated and concentrated to recover salt, and the concentrated solution and sludg...

Embodiment 2

[0031] (1) Get 1 ton of waste incineration fly ash, measure the total salt content of waste incineration fly ash to be 15.6%, mix the three according to the mass ratio of waste incineration fly ash: dechlorination co-solvent: water=80: 12: 8 Uniform, granulated and shaped, the green body is 10mm in diameter and 10mm in length, and the dechlorination co-solvent is activated alumina and fluorite;

[0032] (2) The sintered green body is sintered at 850°C for 20 minutes, and the flue gas generated by sintering is treated with rapid cooling to reduce the temperature of the flue gas to below 200°C, and then collected twice by a bag filter Fly ash, the secondary fly ash is 6.3% (dry weight) of the original ash;

[0033] (3) Stir the collected secondary fly ash with MBR effluent and wash it with water. The washed fly ash is 18.4% (dry weight) of the secondary fly ash. The fly ash is returned to the sintering device for sintering again. The waste heat is evaporated and concentrated to...

Embodiment 3

[0038] (1) Get 1 ton of waste incineration fly ash, measure the total salt content of waste incineration fly ash to be 13.3%, mix the three according to the mass ratio of waste incineration fly ash: dechlorination co-solvent: water=76:15:9 Uniform, granulated and shaped, the green body has a diameter of 6mm and a length of 8mm, and the dechlorination auxiliary solvent is iron oxide and potassium carbonate;

[0039] (2) The sintered green body is sintered at 1000°C for 10 minutes, and the flue gas generated by sintering is treated with rapid cooling to reduce the temperature of the flue gas to below 200°C, and then collected twice by a bag filter Fly ash, the secondary fly ash is 8.1% (dry weight) of the original ash;

[0040](3) Stir the collected secondary fly ash with RO concentrated water for water washing. The washed fly ash is 21.5% (dry weight) of the secondary fly ash, and return to the sintering device for sintering again. Evaporation and concentration treatment recov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com