Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

A harmless treatment and biochemical treatment technology, applied in the field of environmental engineering, can solve problems such as lack of resource recovery, and achieve the effect of reducing pollution and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

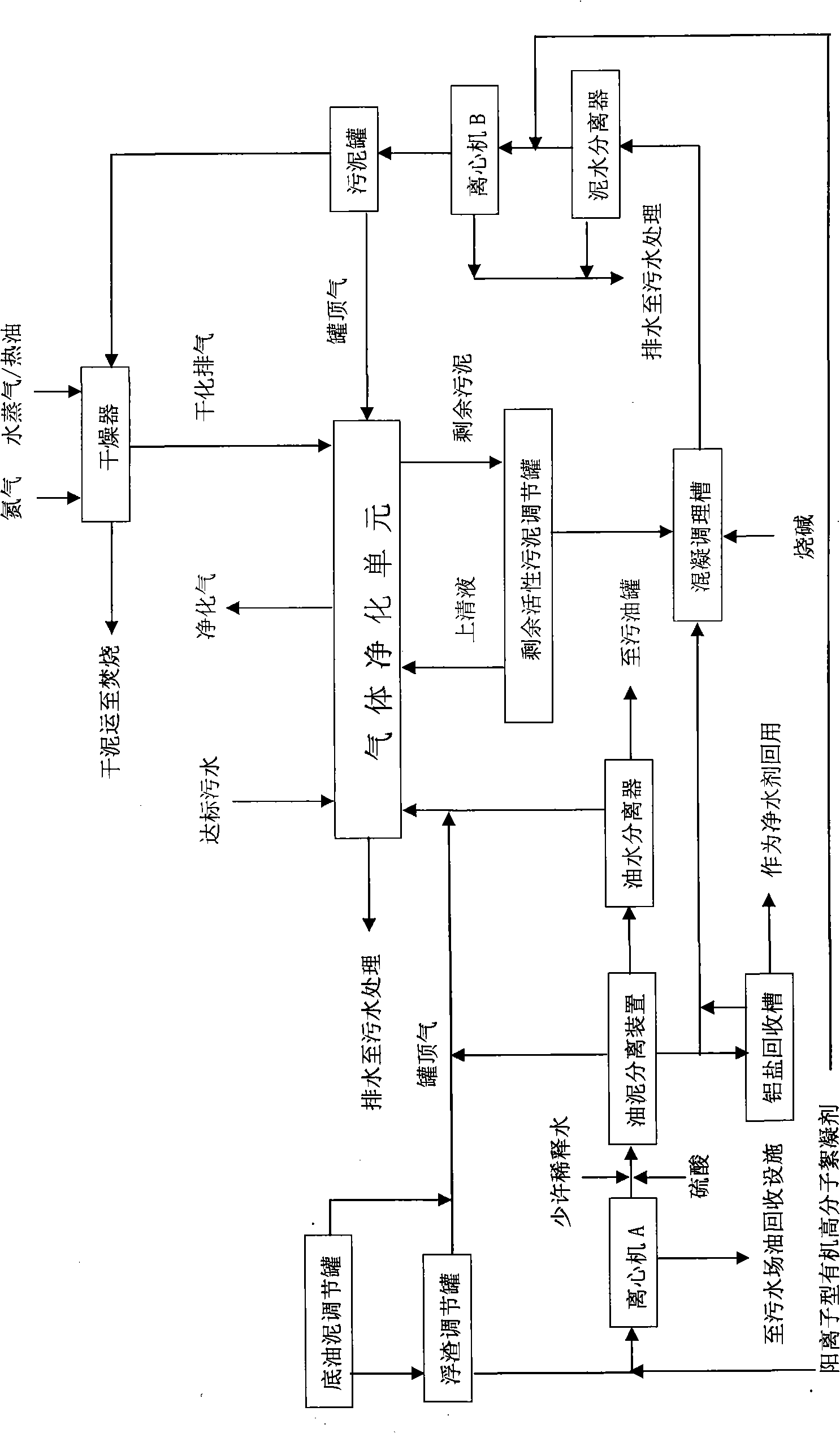

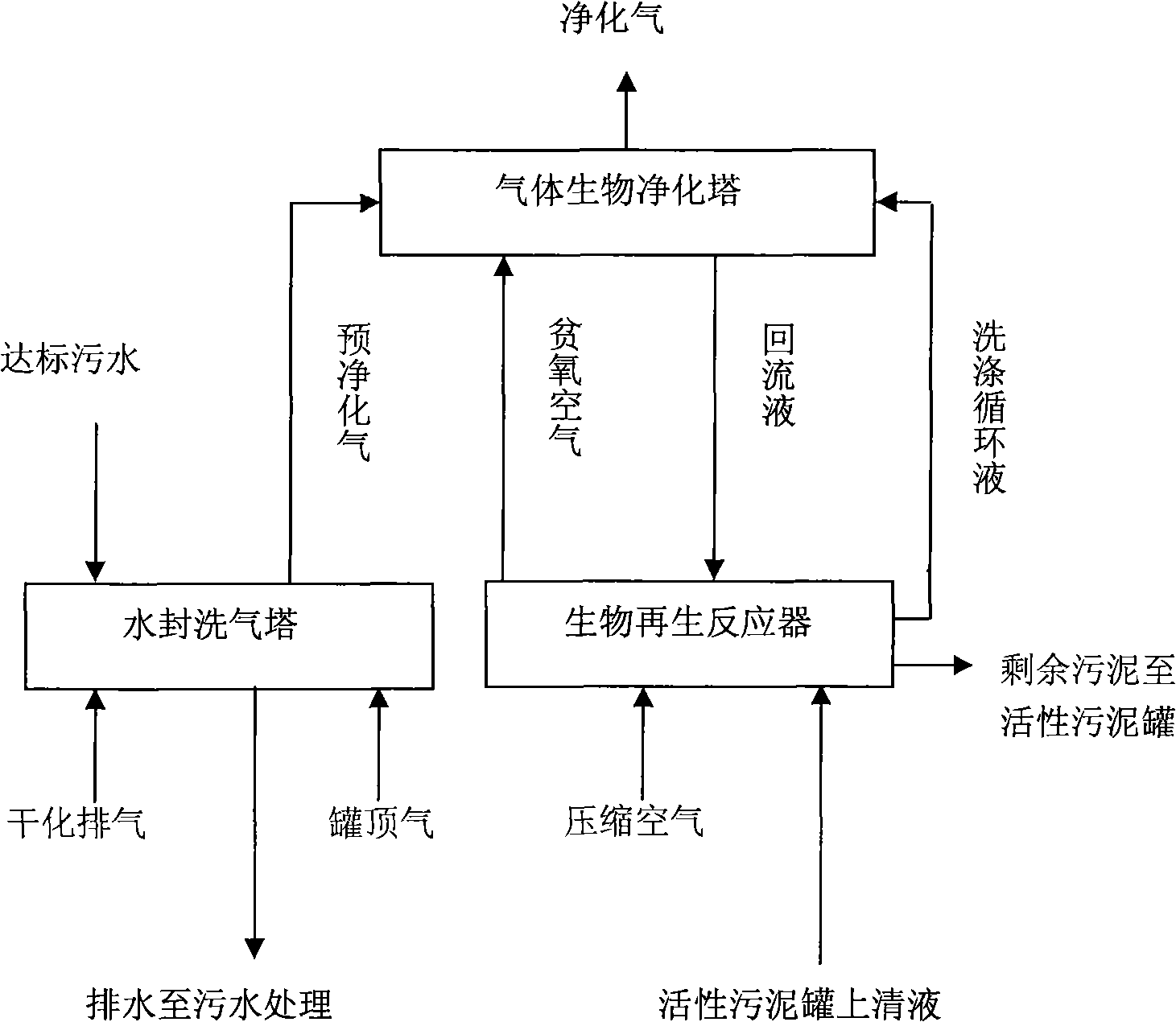

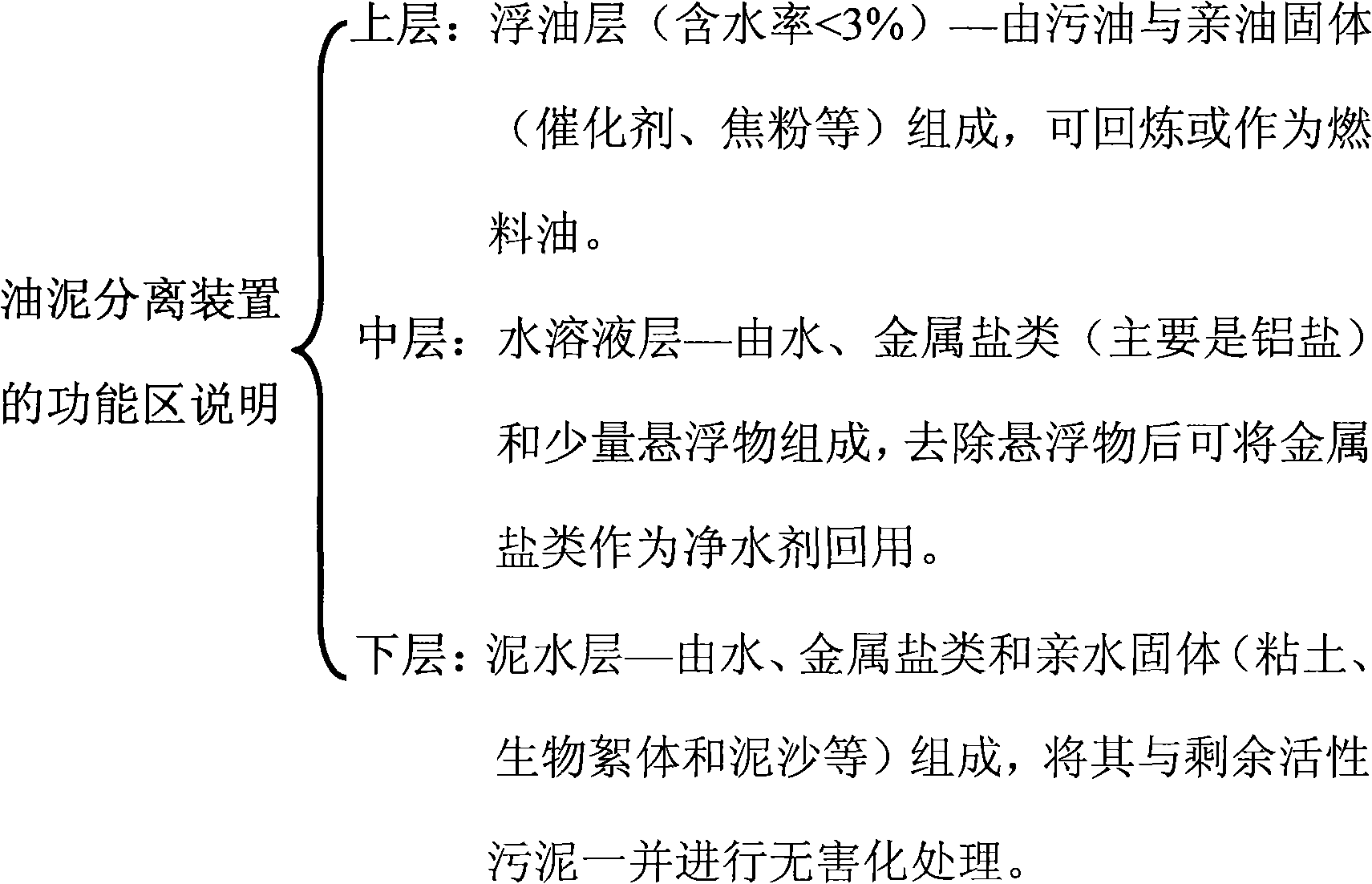

Method used

Image

Examples

Embodiment 1

[0045] (1) Pretreatment of bottom sludge and scum: The bottom sludge in the bottom sludge regulating tank (Φ4000×8000 bottom sludge regulating tank produced by Xi'an Xiangde Environmental Protection Technology Co., Ltd.) is continuously and quantitatively raised to scum In the regulating tank (Φ4000×8000 type scum regulating tank produced by Xi'an Xiangde Environmental Protection Technology Co., Ltd.), the scum is mixed and adjusted together; Polydimethylaminomethacrylamide is added to the pipe to carry out flocculation conditioning on the negatively charged solid particles due to the adsorption of petroleum substances on the surface; the sludge after flocculation conditioning is preliminarily degreased and conditioned by a centrifuge. Dehydration treatment reduces the liquid content of the sludge (including water and petroleum substances) from 95% to 98% to about 80%; the discharged oil-water mixture enters the oil recovery facility in the sewage field for dehydration and reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com