Efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements

A technology for optical components and process equipment, applied in grinding/polishing equipment, metal processing equipment, optical surface grinders, etc. Convergence efficiency and final machining accuracy, efficiency improvement, and sag suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

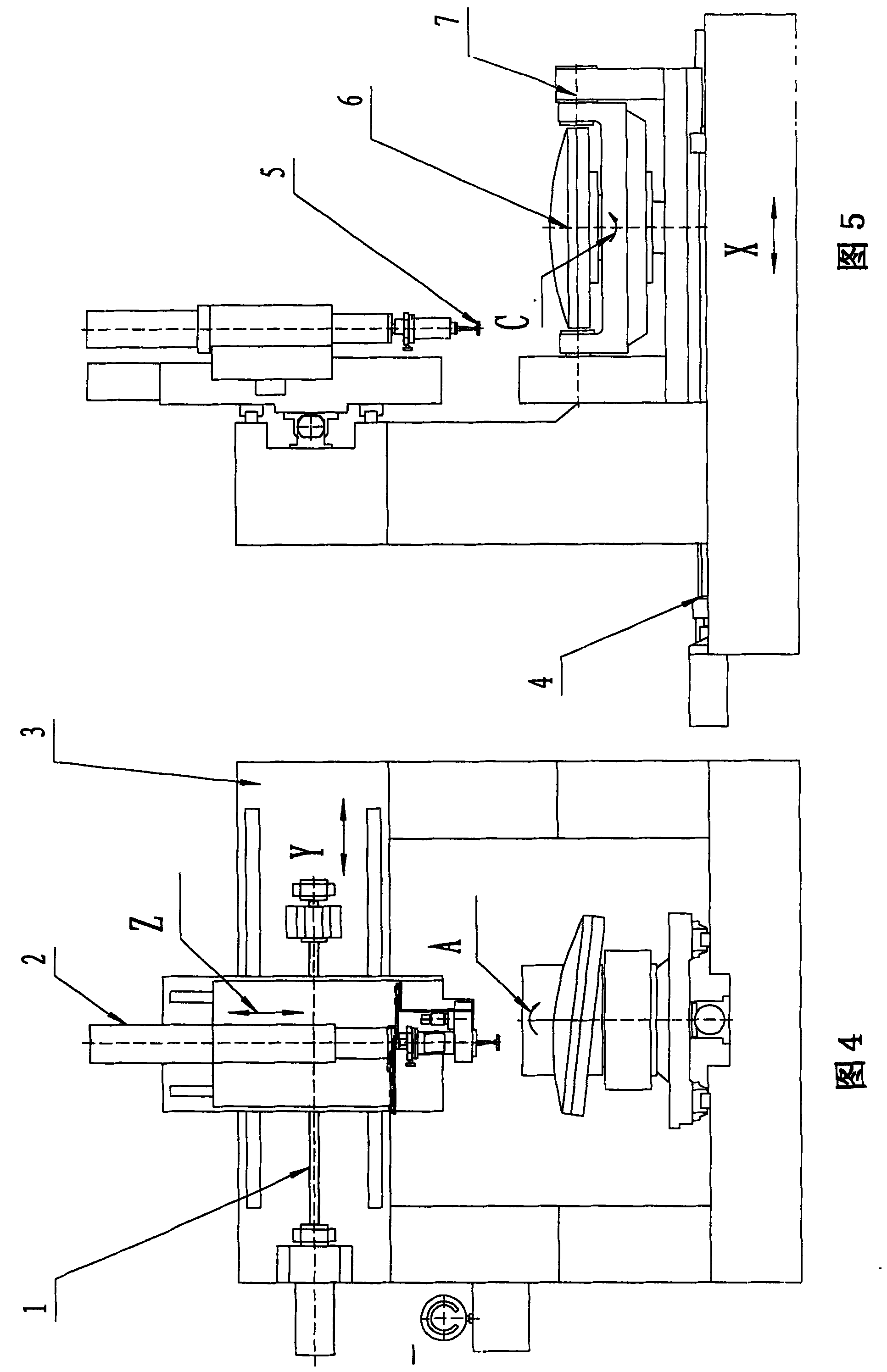

[0057] As shown in Figures 4 and 5, among them: 1 is the Y axis, 2 is the Z axis, 3 is the bed, 4 is the X axis, 5 is the polishing grinding head, 6 is the C axis, and 7 is the A axis; as shown in Figure 9 As shown, 11 is an adjusting screw, 12 is a piston rod, and 13 is a cylinder; as shown in Figure 10, 21 is a shaft, 22 is a worm wheel, and 23 is an expansion sleeve.

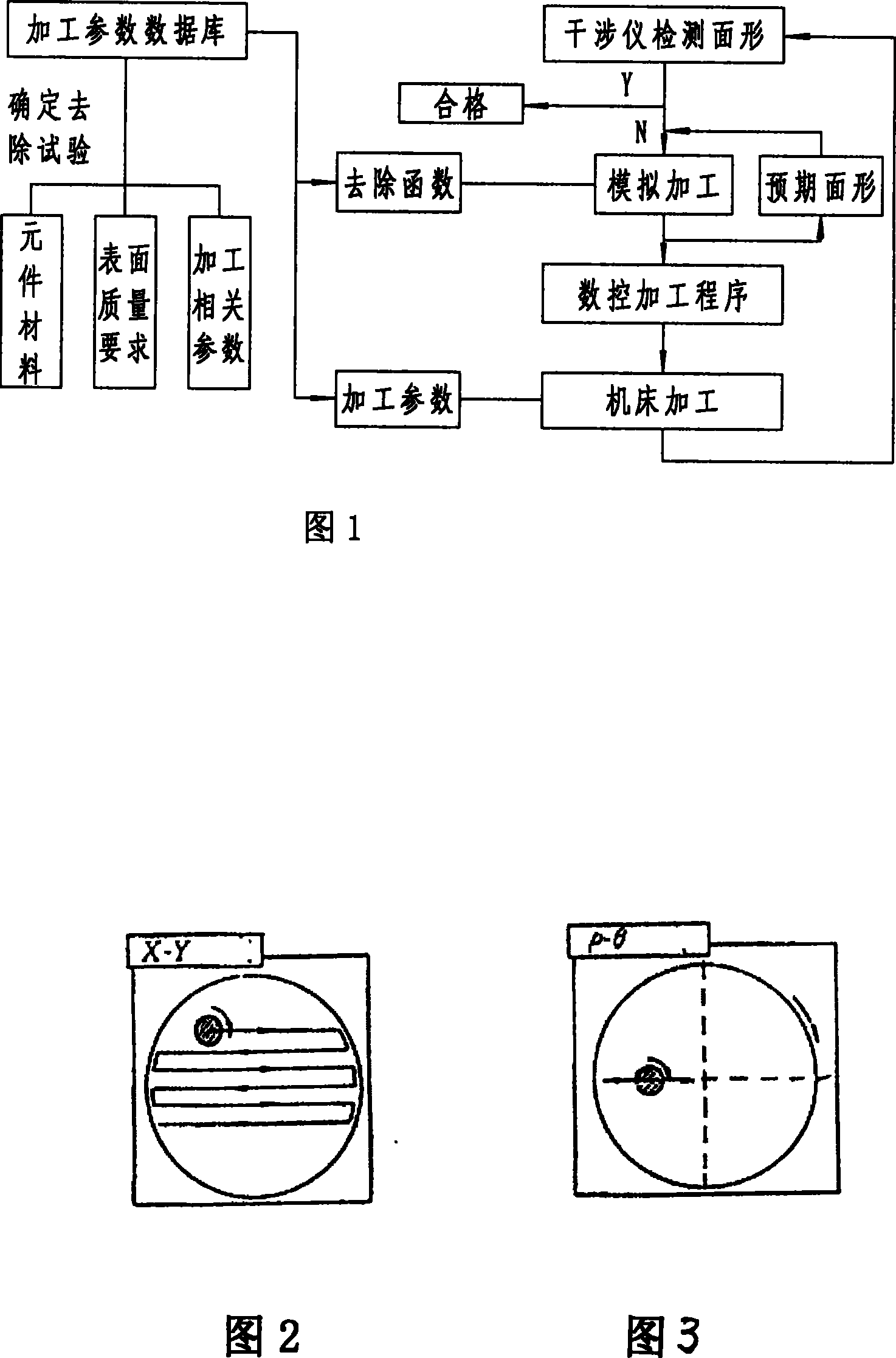

[0058] In the polishing process, since the five-axis four-linkage CNC is used to realize the polishing process, two polishing paths of Cartesian coordinates or polar coordinates can be selected at will according to the structural characteristics of the workpiece, as shown in Figures 2 and 3. In the polishing process, only three-axis numerical control linkage is needed to realize the polishing process of aspheric optical elements.

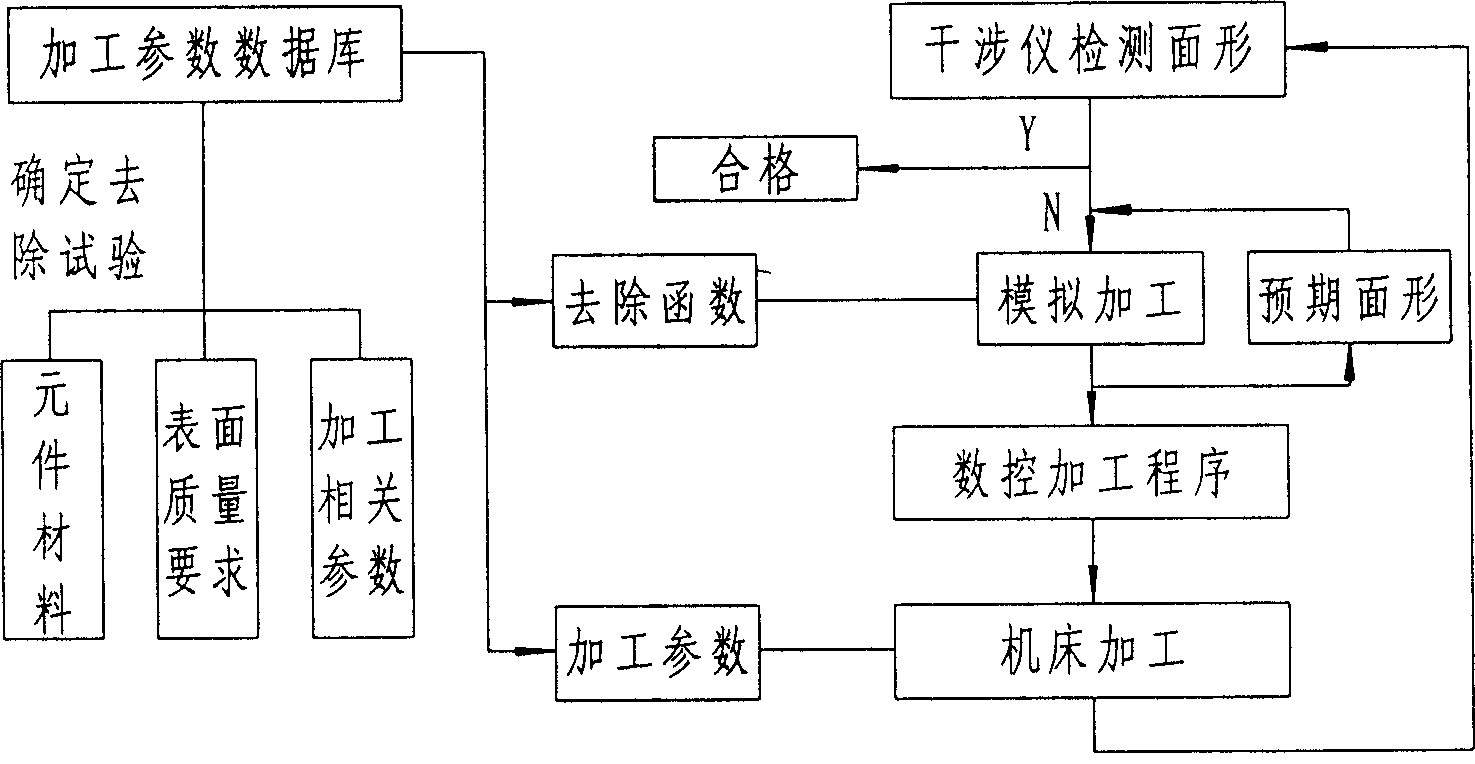

[0059] Aiming at the difficulties encountered in the NC machining process, a new NC optimization process software CCOS2 was developed, which followed the NC polishing process contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com