Complete equipment and method for wet processing of sludge incineration offgas

A sludge incineration and wet treatment technology, which is applied in the directions of combined devices, separation methods, chemical instruments and methods, can solve the problems of backward sludge incineration tail gas treatment technology, poor sludge adaptability, and low treatment efficiency. To achieve the effect of good dust removal, low cost and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

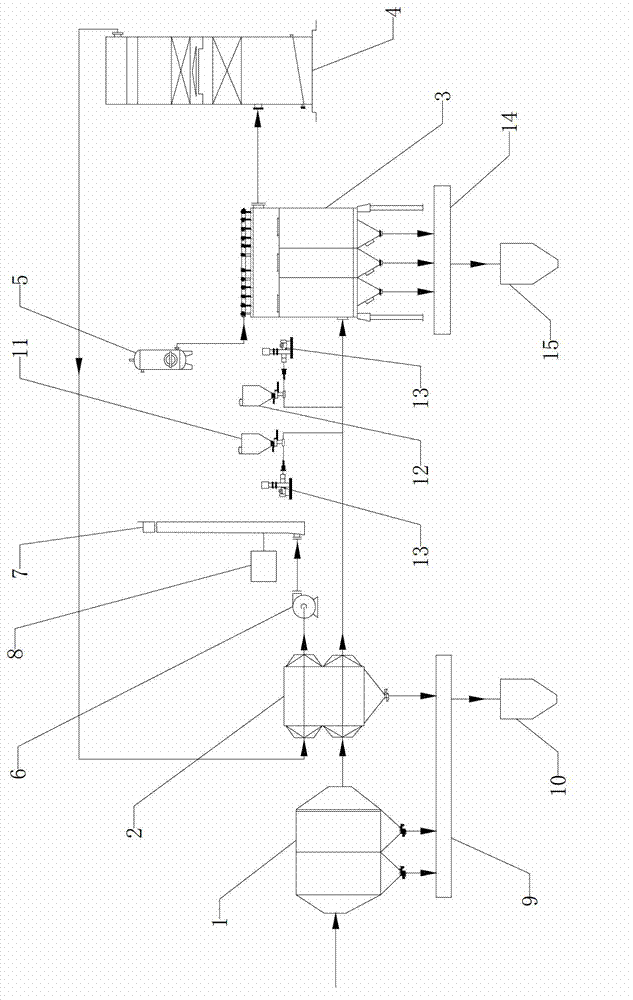

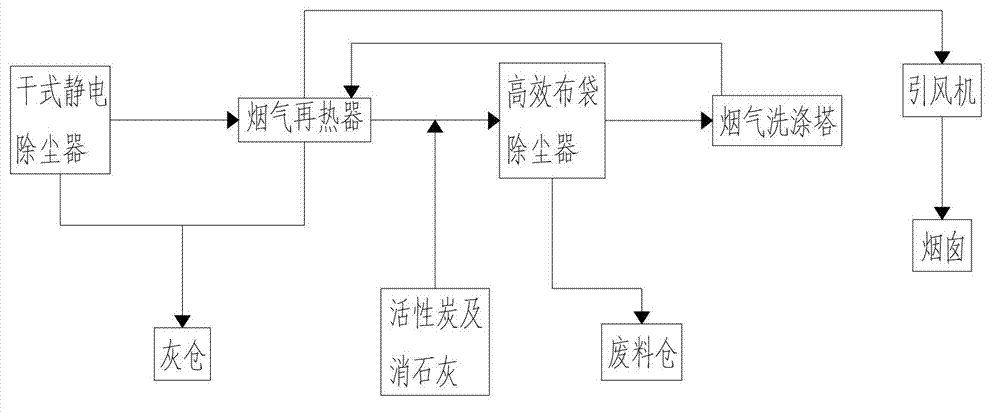

[0031] like figure 1 As shown, a complete set of equipment for wet treatment of sludge incineration tail gas, including a dry electrostatic precipitator 1, a flue gas reheater 2, a bag filter 3 and a flue gas scrubber 4, the dry electrostatic precipitator 1 One end is connected to the sludge incineration exhaust gas pipeline, the other end of the dry electrostatic precipitator 1 is connected to the flue gas reheater 2 through the pipeline, and the right side wall of the flue gas reheater 2 near the bottom is connected to the bag filter 3 through the pipeline , the top of the bag filter 3 is connected to the compressed air tank 5 through a pipeline, the right side wall of the bag filter 3 near the top is connected to the flue gas scrubber 4 through a pipeline, and the right side wall of the flue gas scrubber 4 is connected to the top side through a pipeline The flue gas reheater 2 is connected, and the right side wall of the flue gas reheater 2 near the top is connected to the ...

Embodiment 2

[0047] Relying on the Shanghai Zhuyuan sludge treatment project, the complete set of equipment for wet treatment of sludge incineration tail gas mainly includes: dry electrostatic precipitator for dust removal; bag filter for dust, activated carbon particles and attached dioxins Removal of pollutants such as British and heavy metals; adsorption of organic matter (dioxin) and heavy metals by activated carbon; removal of acid gases (HCl, HF, SOx) by slaked lime and flue gas scrubber, including the following steps:

[0048] (1) The tail gas from sludge incineration (at a temperature of 230°C) first enters the dry electrostatic precipitator, and relies on the two systems of the corona electrode and the sedimentation electrode of the precipitator to absorb dust, and uses shock vibration to peel off the dust on the electrode. Most of the dust is removed, and general solid waste is produced, which is transported to the ash bin, and the dust removal efficiency can reach more than 99%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com