Method for recovering phosphorus and removing heavy metals from sludge separate incineration ash residues

A technology for incineration of ash and sludge, applied in chemical instruments and methods, non-metallic elements, phosphorus compounds, etc., can solve problems such as ineffective removal of heavy metal ions, secondary pollution of the environment, etc., and achieve phosphorus recovery and treatment scale Small size, large amount of phosphorus recovery, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

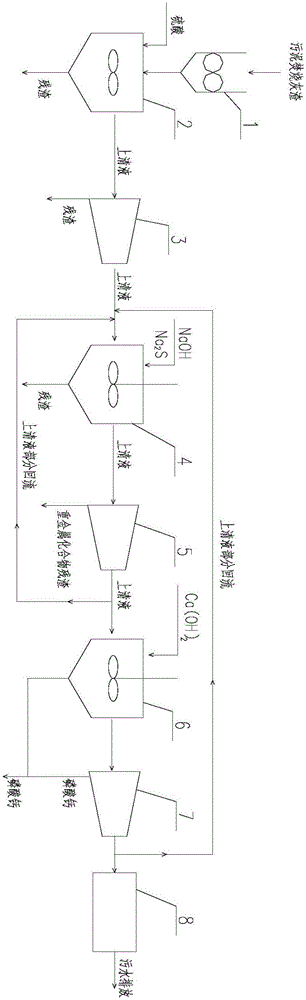

Image

Examples

specific Embodiment

[0031] Specific example: sludge incineration ash was dried in a blast oven at 105°C for 24 hours, ground and passed through an 80-mesh sieve for storage until use. Three groups of parallel samples were taken, and the national standard method was used to determine the content of total phosphorus and the ICP-AES method to determine the content of heavy metals Cu, Cd, and Zn. Weigh 5g of the dried sludge incineration ash, weigh 1mol / L sulfuric acid according to the solid-liquid mass ratio of 8-12:1, put the mixed solution in a beaker, stir the reaction at a medium speed on a magnetic stirrer for 12 hours, add sulfuric acid halfway to control The pH is between 1-3. After the reaction, the mixed solution enters the first centrifugal separator for separation. The separator rotates at 5000 rpm and the separation time is 20 minutes. Measure the volume of the supernatant and extract part of the supernatant to determine the total phosphorus and heavy metal content. Put the supernatant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com