Closed machinery incineration treatment method for half-dry sludge

A treatment method and technology for drying sludge, which can be used in dewatering/drying/concentrating sludge treatment, combustion methods, incinerators, etc., which can solve the problem of difficulty in finding landfill sites, high sludge incineration costs, and high sludge moisture content. problems, to ensure that the calorific value is not lost, the cost of sludge incineration is low, and the pollution is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

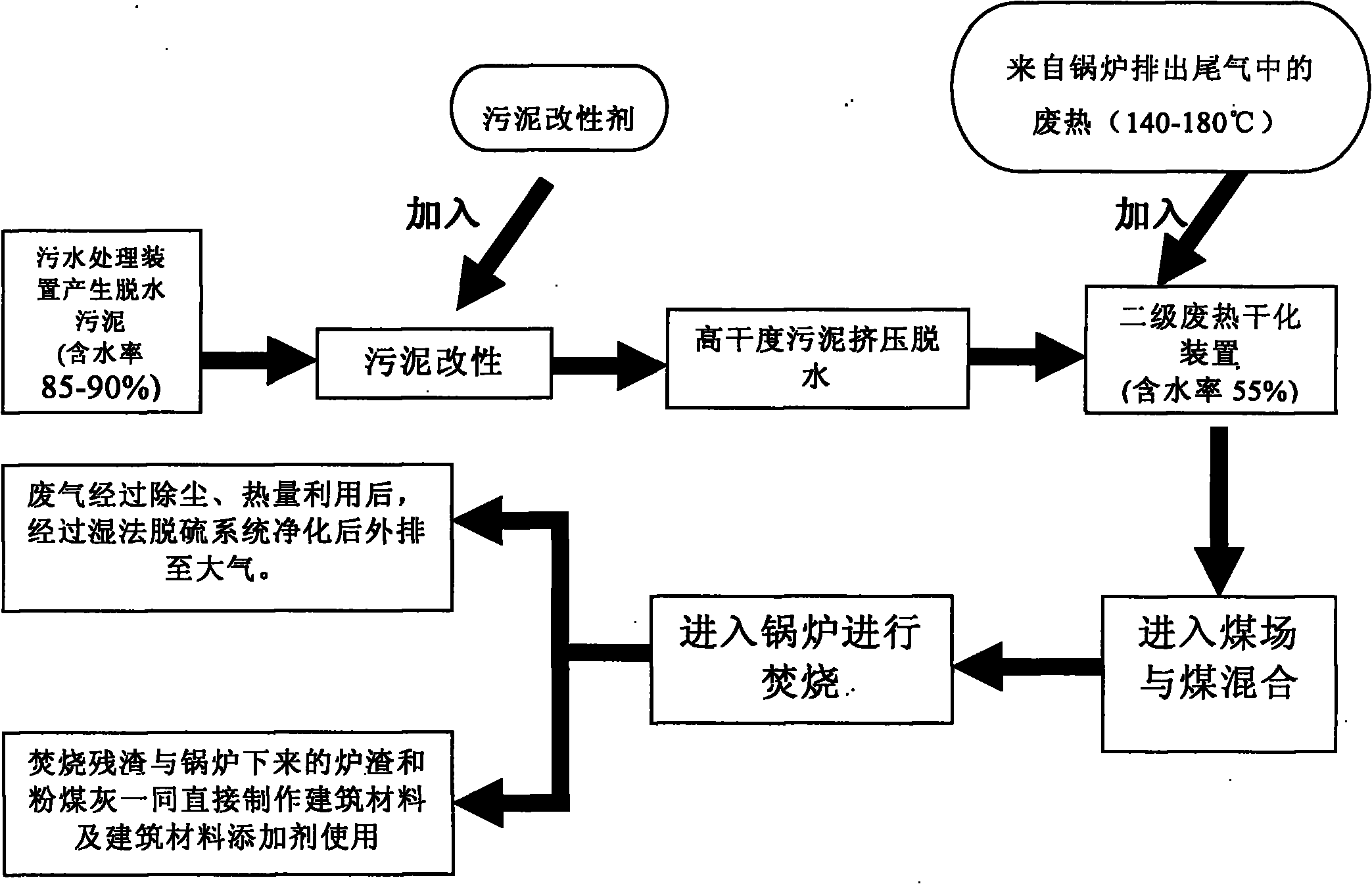

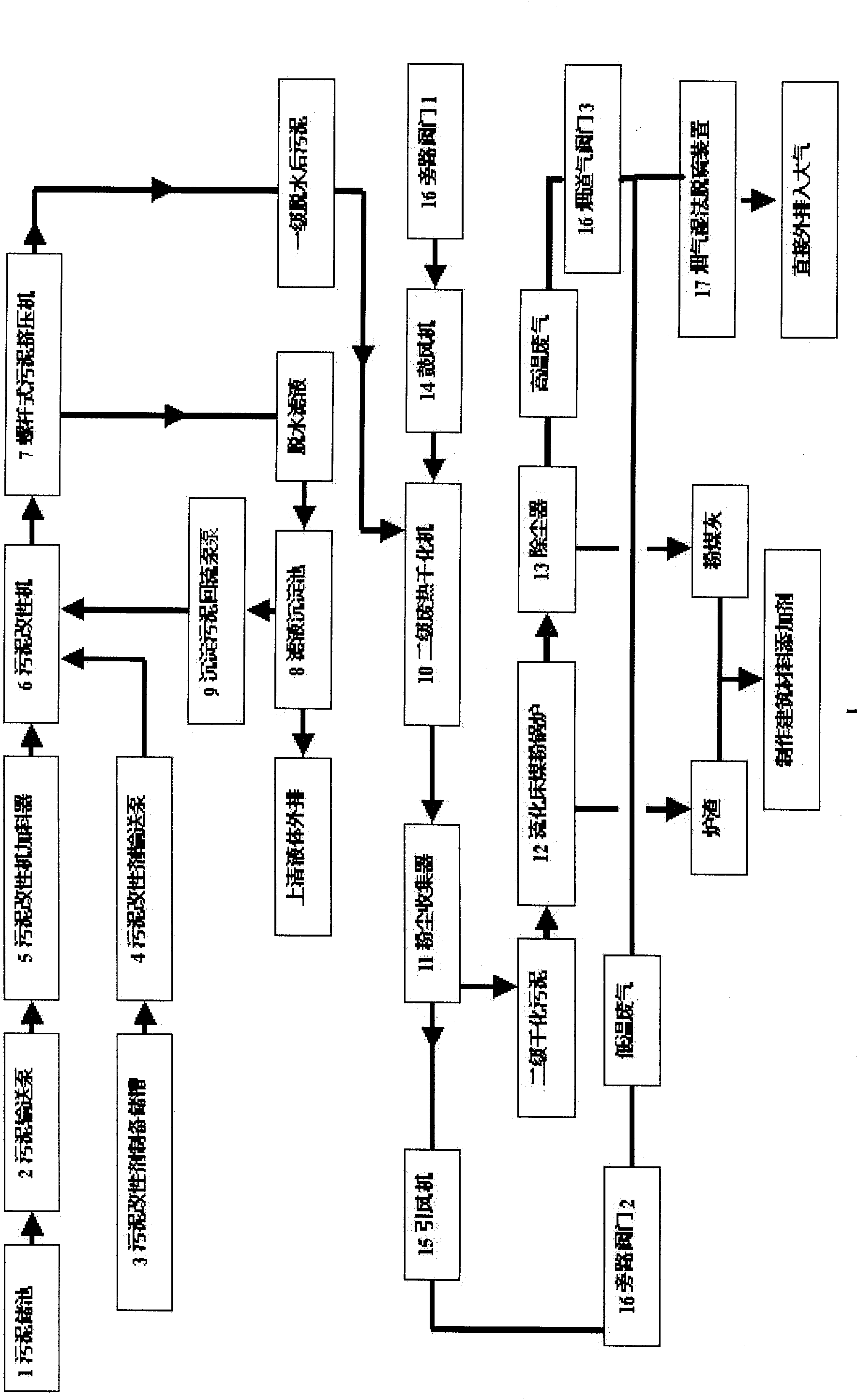

[0022] Such as figure 1 Shown, a kind of closed mechanical semi-dry incineration treatment method, it comprises the following steps:

[0023] Step 1, sludge modification, using a modifier to reduce the viscosity of the sludge, the binding force between the sludge and the water in the sludge, and the strength of the sludge particles;

[0024] Step 2, extruding the sludge for dehydration, reducing the water content of the sludge to 75%, and becoming loose granular sludge;

[0025] Step 3, using waste heat to further dry the sludge to reduce the water content of the sludge to 55%;

[0026] Step 4, mixing the sludge and coal with a moisture content of 55% obtained in step 3;

[0027] Step 5, sending the sludge-coal mixture obtained in Step 4 to the boiler for combustion, and its tail gas is dedusted and desulfurized as a waste heat source in Step 2;

[0028] In step six, the slag and coal ash left over from the sludge incineration in step five are used as building materials and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com