Bubbling bed sludge incineration boiler and sludge incineration method

A technology of sludge incineration and bubbling bed, applied in the direction of combustion method, incinerator, combustion type, etc., to achieve full recycling, reduce combustion loss, and improve boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

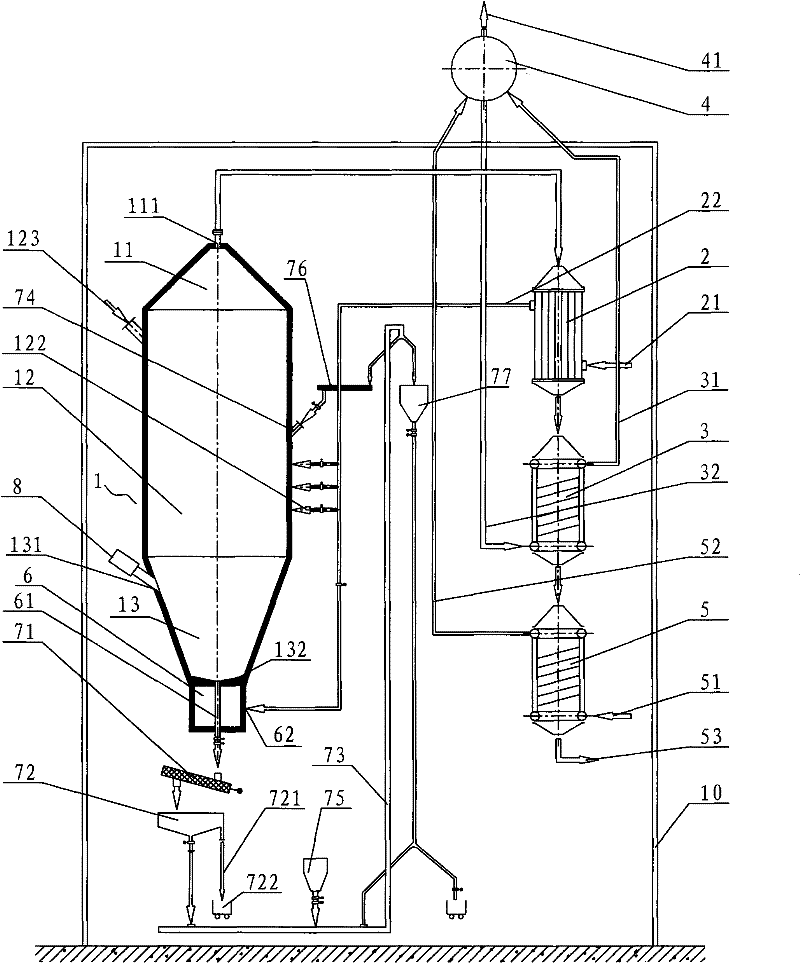

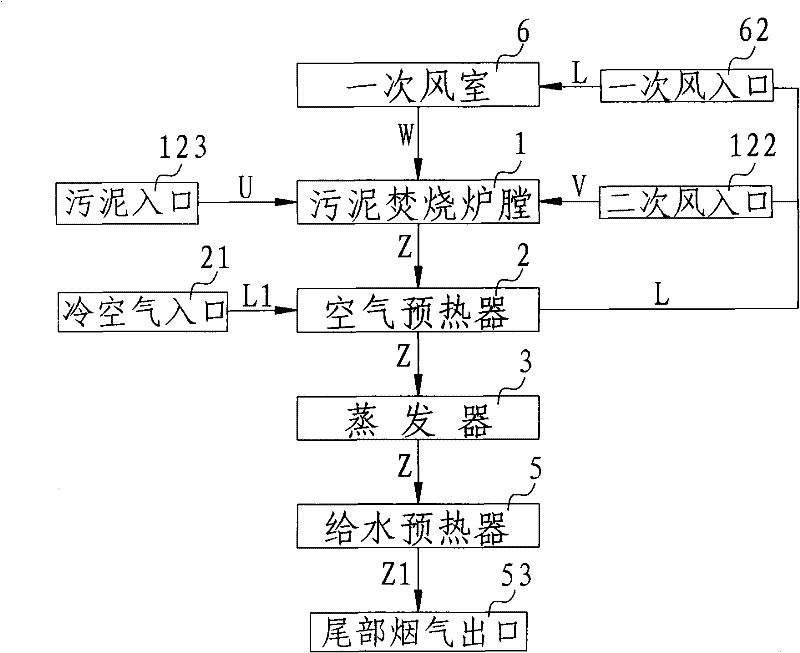

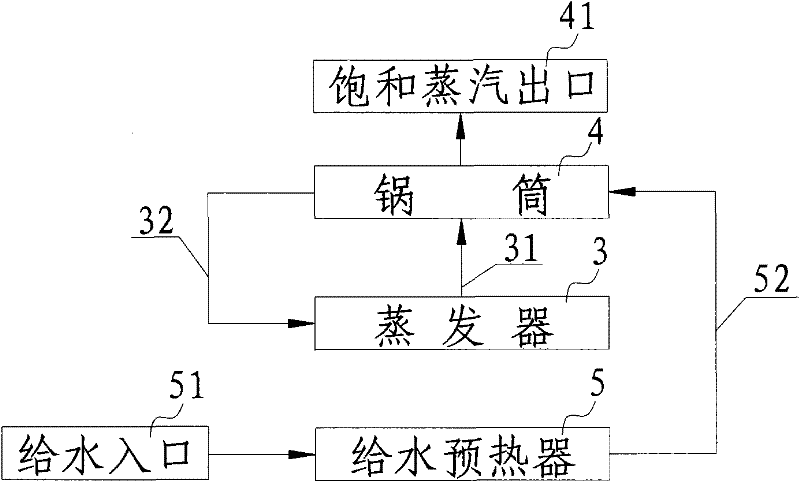

[0062] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0063] In order to solve the problems of high moisture content in sludge and low calorific value, poor combustion stability, low furnace combustion temperature affecting dioxin decomposition, and highly corrosive acid gas in flue gas, the present invention adopts Unlike conventional fluidized bed boiler designs.

[0064] When the sludge is incinerated after drying, it is composed of very fine particles, which can be completely burned in one flow in the furnace, so the present invention adopts the method of bubbling bed for incineration, and does not use a cyclone separator to form a fly ash circulation A method of performing multiple burns.

[0065] The water content of the sludge sent by the sewage treatment plant is about 90%, and the calorific value is very low, about 1200kj / kg. Sludge must be dry to be ignited, so heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com