Sludge drying and incinerating integrated treatment system and process thereof

A sludge drying and sludge incineration technology, applied in the field of sludge treatment system and its process, can solve the problems of energy loss, high processing energy consumption, poor economy of sludge drying and incineration treatment process route, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

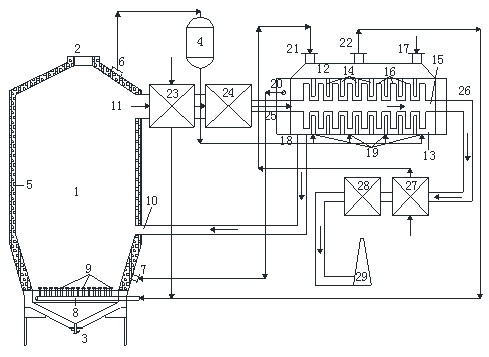

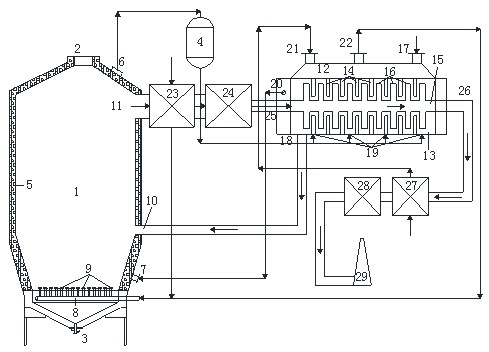

[0017] Such as figure 1 As shown, the sludge drying and incineration integrated treatment system includes a sludge incinerator 1, a steam drum 4, a sludge drying unit 12, an air preheater 23, a dust collector 24, a carrier gas preheater 27, and a desulfurization unit 28 And chimney 29, sludge incinerator 1 includes flue gas explosion-proof door 2, slag discharge port 3, membrane water wall 5, steam outlet 6, circulating water inlet 7, air distribution plate 8, air cap 9, dry sludge feeding port 10 , the flue gas outlet 11, the sludge drying unit 12 includes an outer wall 13, a fixed paddle 14, a hollow shaft 15, a rotating paddle 16, a wet sludge inlet 17, a dried sludge outlet 18, and a steam heat source inlet 19. Steam heat source outlet 20, carrier gas inlet 21, drying exhaust gas outlet 22, flue gas heat source inlet 25, flue gas heat source outlet 26;

[0018] Sludge incinerator 1. Membrane water wall 5 is installed on the furnace wall, flue gas explosion-proof door 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com