Two-stage drying and incineration method for sludge

A two-stage, sludge technology, applied in combustion methods, dehydration/drying/thickened sludge treatment, incinerators, etc., can solve high operating costs, limited sludge treatment volume, high energy consumption of sludge incineration technology, etc. problems, to achieve the effects of avoiding secondary pollution, excellent air permeability, and low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be described in further detail with reference to the drawings and specific embodiments. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

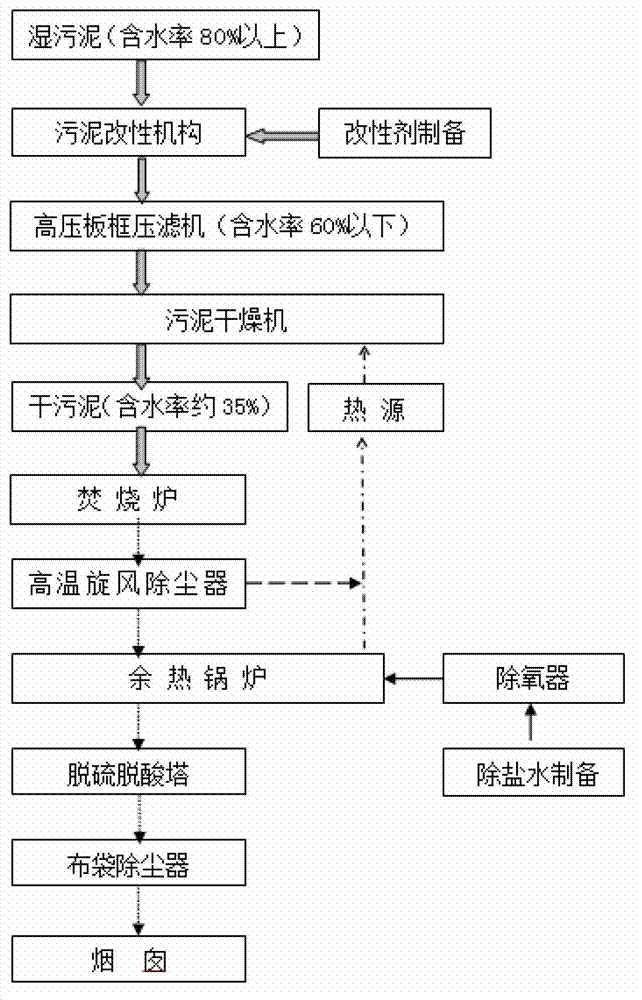

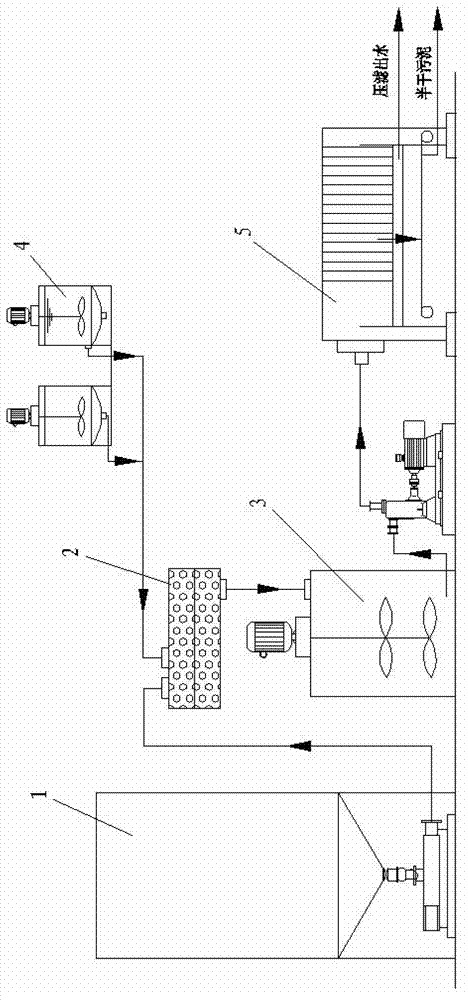

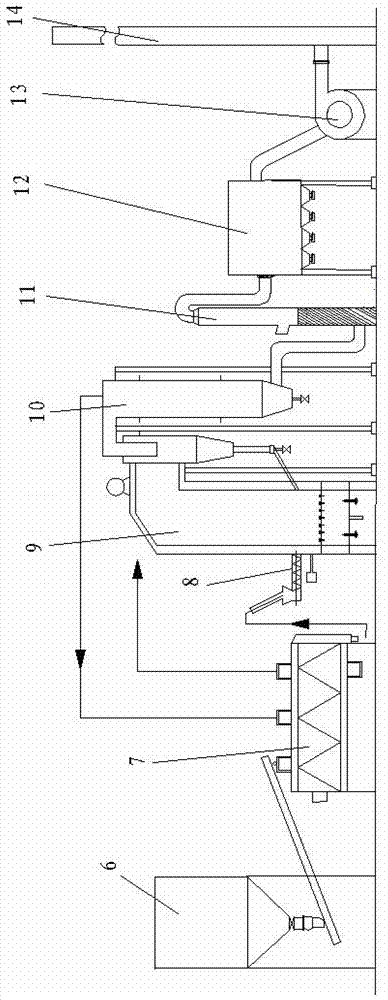

[0027] Such as figure 1 As shown, the "two-stage" dry incineration process of sludge is as follows. Wet sludge with a moisture content of more than 80% is chemically modified and dried to make the moisture content 45% to 60%, and then dried with steam The technology performs two-stage drying to reduce the moisture content of the sludge to 35%; dry sludge with a moisture content of 35% enters the sludge incinerator for incineration, and the waste heat generated is enough to reduce the moisture content of the sludge from 60% to 35%. Add any auxiliary fuel; the high-temperature flue gas produced by incineration enters the waste heat boiler to produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com