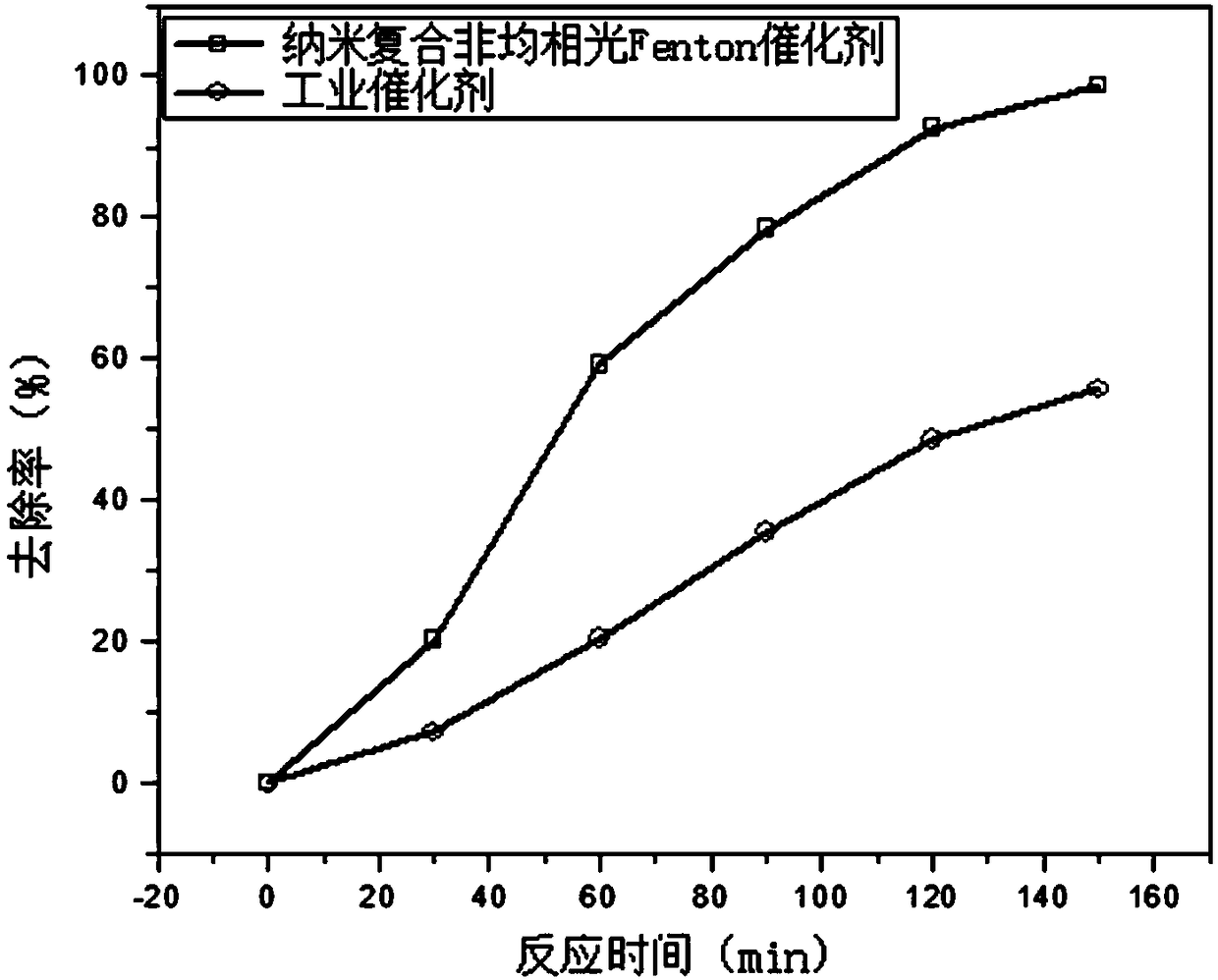

Nanocomposite heterogeneous photo-Fenton catalyst and preparation method and application thereof

A nano-composite material and catalyst technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Uniformity and other problems, to achieve the effect of low price, overcoming loss, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

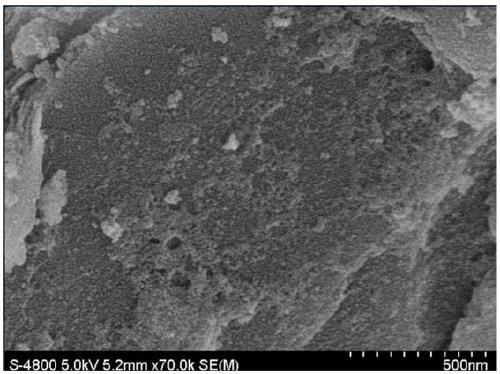

Image

Examples

Embodiment 1

[0033] ①Dry the sludge from the urban domestic sewage treatment plant at 120°C for 12 hours, then pulverize it, and sieve it through a 50-mesh sieve to obtain a sludge powder sample that passes through the sieve. Calcined at 500° C. for 4 hours under the condition of feeding air, and after cooling to room temperature, the sludge catalyst carrier was obtained.

[0034] ②Weigh 0.898gFe(NO 3 ) 3 9H 2 O, 0.067g InN 3 o 9 ·xH 2 O was added to 50mL deionized water (Fe(NO 3 ) 3 9H 2 O and InN 3 o 9 ·xH 2 (2 molar ratio is 10:1), in above-mentioned solution, add cetyltrimethylammonium bromide (CTAB) 0.1g, after magnetic stirring makes it mix uniformly, react under microwave radiation condition, temperature is 100 ℃, The power is 200W, the reaction time is 20min, and cooled to room temperature to obtain the nano-metal composite precursor solution.

[0035] ③ Add 3 g of the sludge catalyst carrier in ① to the precursor solution obtained in ②, stir it magnetically for 1 hour,...

Embodiment 2

[0038] ① Dry the sludge from the urban domestic sewage treatment plant at 120°C for 12 hours, then pulverize it, and sieve it through a 100-mesh sieve to obtain a sludge powder sample that passes through the sieve. Calcined at 400° C. for 5 hours under the condition of feeding air, and after cooling to room temperature, the sludge catalyst carrier was obtained.

[0039] ②Weigh 0.844gFe(NO 3 ) 3 9H 2 O, 0.442g Sr(NO) 2 Added to 50mL deionized water (Fe(NO 3 ) 3 9H 2 O and Sr(NO) 2 The molar ratio is 1:1), add 0.1g of cetyltrimethylammonium bromide (CTAB) to the above solution, stir it with magnetic force to make it evenly mixed, and then react under the condition of microwave radiation, the temperature is 80 ℃, the power The temperature is 300W, the reaction time is 30min, and cooled to room temperature to obtain a nano-metal composite precursor solution.

[0040] ③ Add 3 g of the sludge catalyst carrier in ① to the precursor solution obtained in ②, stir it magnetically...

Embodiment 3

[0043] ①Dry the sludge from the urban domestic sewage treatment plant at 105°C for 12 hours, then pulverize it, and sieve it through a 100-mesh sieve to obtain a sludge powder sample that passes through the sieve. Calcined at 500° C. for 4 hours under the condition of feeding air, and after cooling to room temperature, the sludge catalyst carrier was obtained.

[0044] ②Weigh 1.012gFe(NO 3 ) 3 9H 2 O, 0.608gBi(NO 3 ) 3 ·5H 2 O, 0.126g InN 3 o 9 ·xH 2 O was added to 120mL deionized water (Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O, InN 3 o 9 ·xH 2 (2 molar ratio is 6:3:1), in above-mentioned solution, add cetyltrimethylammonium bromide (CTAB) 0.36g, after magnetic stirring makes it evenly mix, react under microwave radiation condition, temperature is 100 ℃, the power is 200W, the reaction time is 30min, and cooled to room temperature to obtain the nano-metal composite precursor solution.

[0045] ③ Add 3 g of the sludge catalyst carrier in ① to the precursor solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com