System and method for producing cement short flow-process with metallurgical furnace slag

A technology of metallurgical slag and production system, which is applied in the field of short-process cement production system from metallurgical slag, can solve the problems of long process and uncompleted "zero" discharge of steel slag, and achieve the goal of improving recovery rate, benefiting environmental protection and shortening the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

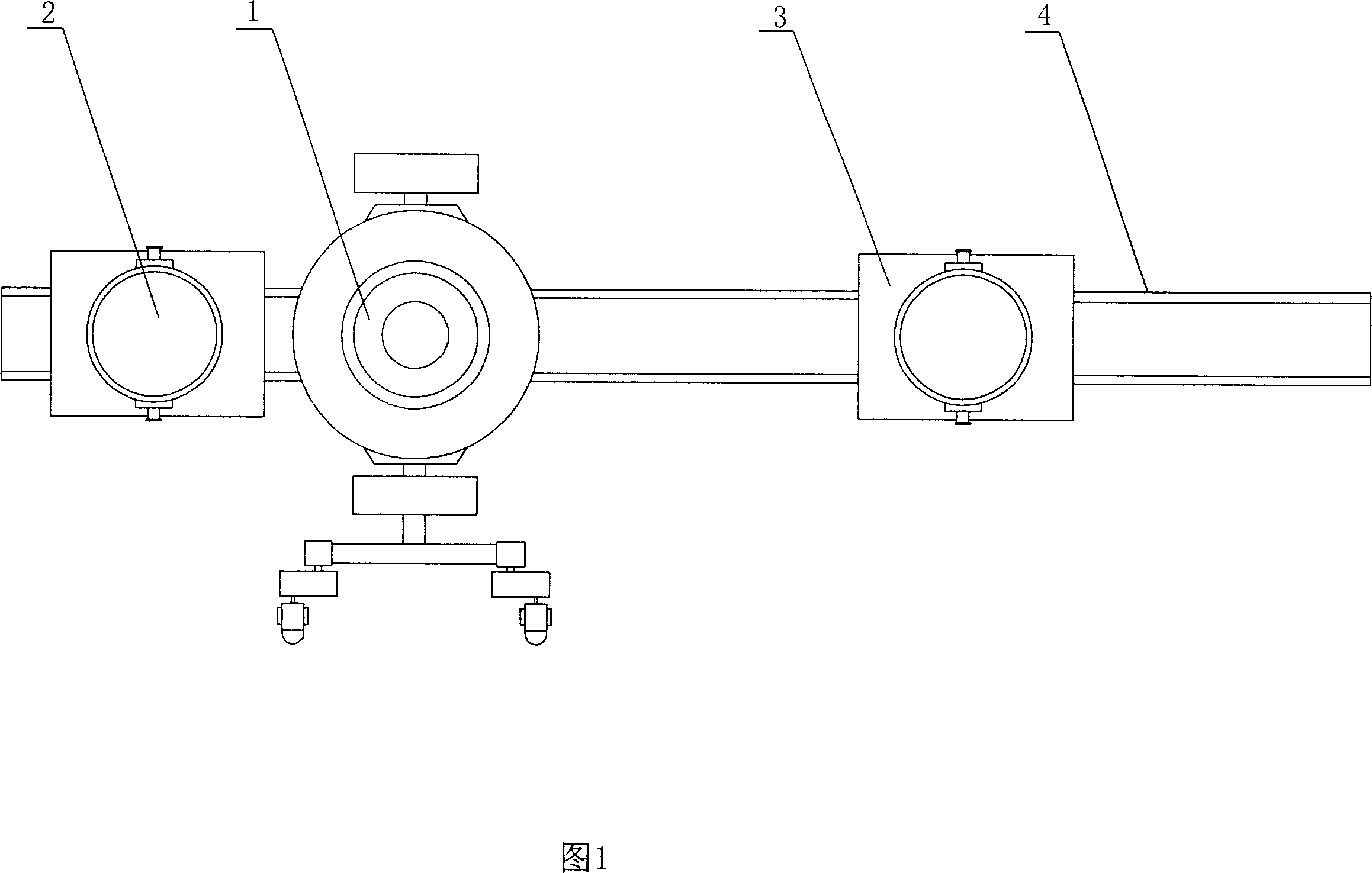

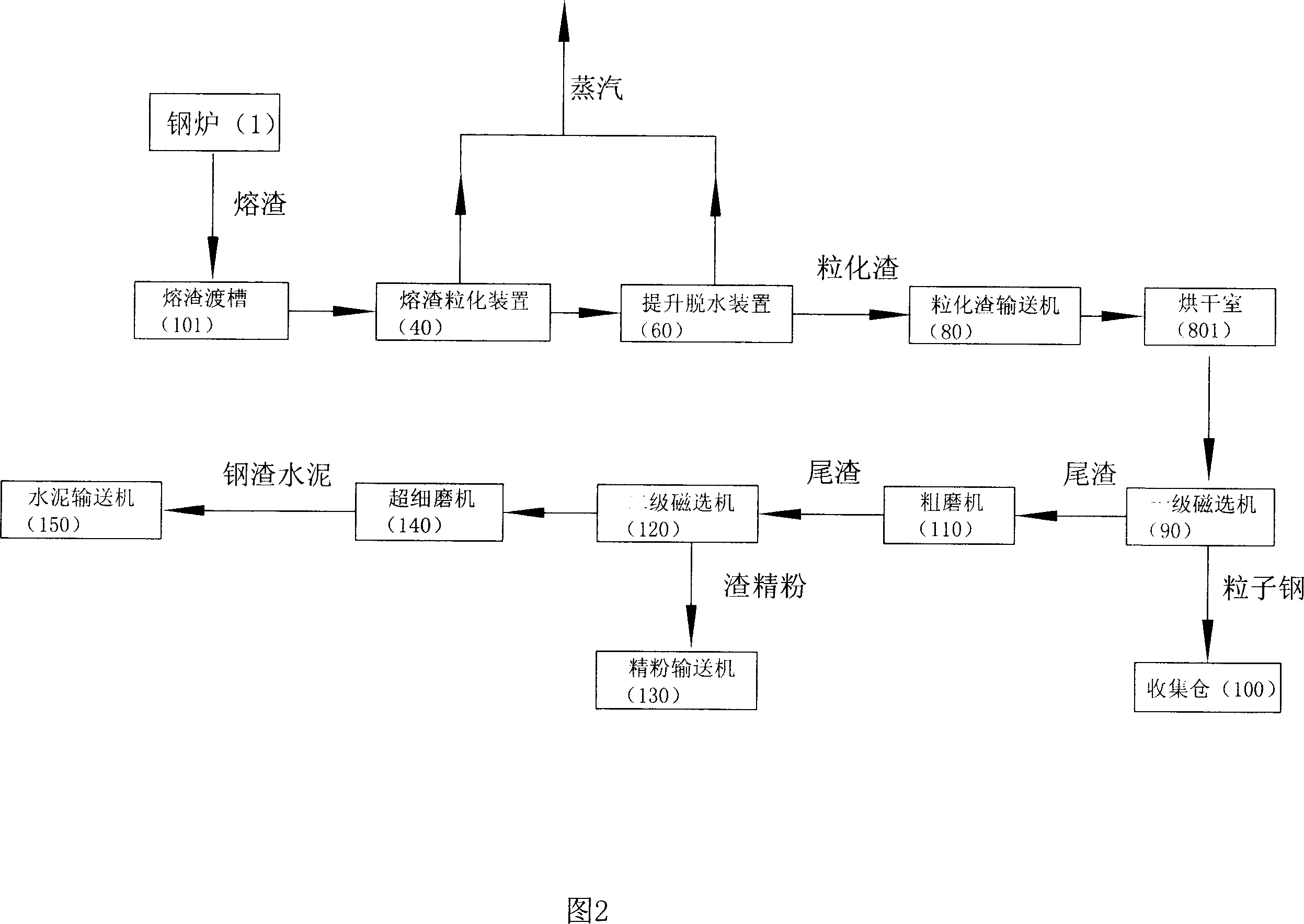

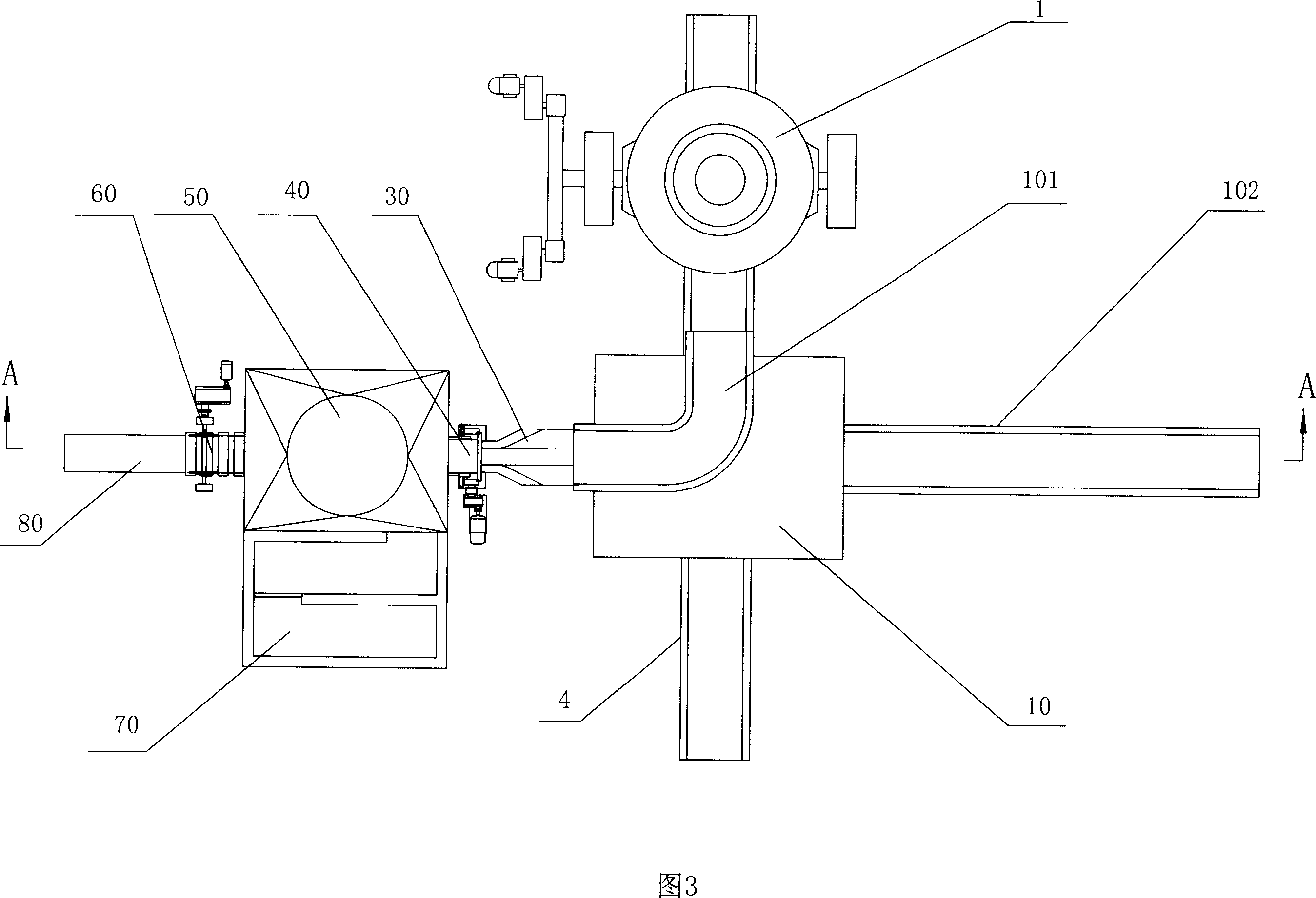

[0035]Referring to Fig. 2, Fig. 3 and Fig. 4, a metallurgical slag cement short-process production system includes a steel furnace 1 (the steel furnace can be a converter or a non-ferrous metal smelting furnace), a slag tank car walking track 4 in front of the furnace, and a slag tank car A slag granulation device 40 is arranged on one side of the walking track, and a slag aqueduct car walking track 102 is arranged on the other side of the slag tank car walking track. 10, a diverted slag aqueduct 101 is installed. In this embodiment, a slag granulation device is arranged on the left side, and a slag aqueduct vehicle is arranged on the right side. The diverted slag aqueduct is a 90° diverted aqueduct, and The running track of the slag aqueduct car and the walking track of the slag tank car are arranged orthogonally. The inlet end of the slag aqueduct can be docked with the slag outlet of the steel furnace 1 (due to the conventional structure, the slag outlet is not shown in the...

Embodiment 2

[0040] Referring to Fig. 5, this embodiment is an improvement on the basis of Embodiment 1. In this embodiment, the diverted slag aqueduct is a 90° diverted aqueduct, and the walking track of the slag aqueduct car and the slag tank car The walking track is set obliquely. That is, the traveling track of the slag aqueduct car and the traveling track of the slag tank car are obliquely arranged at an angle of 30° to 60°. The advantage of oblique setting is to reduce the use area of the equipment.

Embodiment 3

[0042] Referring to Fig. 6 and Fig. 7, this embodiment is an improvement on the basis of the first embodiment. In the production system of this embodiment, it includes a steel furnace 1 and a slag tank car running track 4 in front of the furnace. A slag granulation device 40 is arranged on one side of the slag tank car running track, and a slag aqueduct car is set on the other side of the slag tank car running track. Track 102, one end of the traveling track of the slag aqueduct vehicle intersects with the traveling track of the slag tank vehicle, and a steering type slag aqueduct 101 is installed on the slag aqueduct vehicle 10. In this embodiment, a slag granulation device is arranged on the left side, and the right side A slag aqueduct car is arranged on the side, and the diverted slag aqueduct is a 90°-turned aqueduct, and the traveling track of the slag aqueduct car and the traveling track of the slag tank car are arranged orthogonally. A slag buffer tank 20 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com