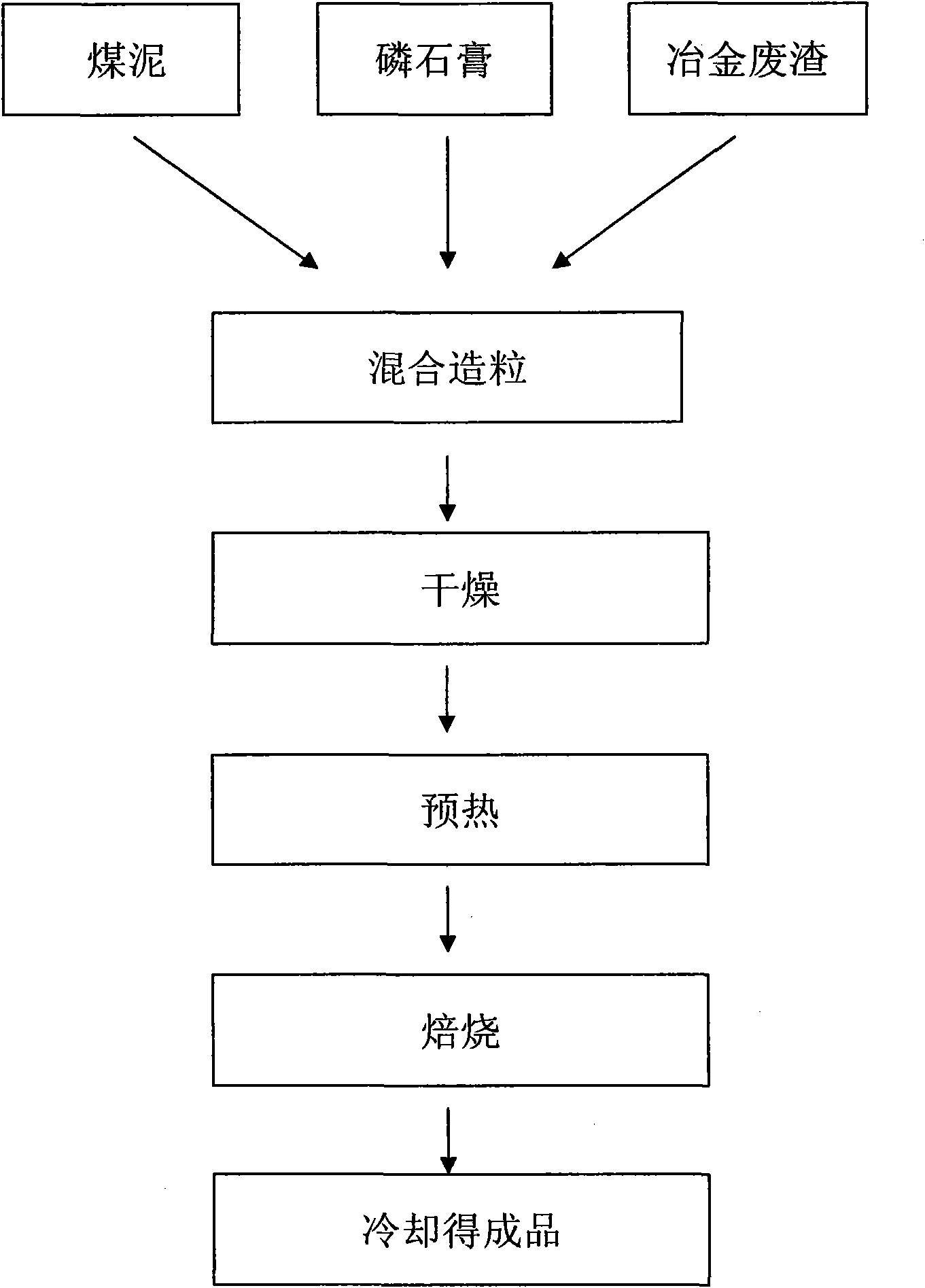

Method for synthesizing ceramsite by coal slurry, ardealite and metallurgical slag

A technology of metallurgical waste slag and phosphogypsum, which is applied in applications, household appliances, and other household appliances. It can solve the problems of mixing and preparing ceramsite that have not been seen before, and achieve the effects of shortening roasting time, large specific surface area, and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Grind coal slime, phosphogypsum, and metallurgical waste slag into powders with a particle size of 120-180 μm at a ratio of 50%: 10%: 40% by mass, add 3% of the raw material weight to mix, and put them on a YK-60 granulator Make balls with a particle size of 5-10mm. During the heating and roasting process, the temperature in the drying stage is controlled at 105±2°C, and dried for 1h; the temperature is raised to 450°C at a rate of 10°C / min, and preheated for 25min; Entering the roasting stage, the temperature is raised to 800°C at a heating rate of 15°C / min, and roasted for 25 minutes; finally, the finished product is obtained by natural cooling. The water absorption rate of the produced ceramsite is ≤15%, the bulk density range is ≤500kg / m3, and the cylinder compressive strength is ≥0.3MPa.

Embodiment 2

[0020] Grind coal slime, phosphogypsum, and metallurgical waste slag into powders with a particle size of 120-180 μm in a mass percentage of 70%:5%:25%, add water accounting for 4% of the raw material weight, and mix them on a YK-60 granulator Make balls with a particle size of 10-20mm, control the temperature in the drying stage at 105±2°C, dry for 1.5h; increase the temperature to 550°C at a rate of 10°C / min, and preheat for 18 minutes; Heating rate The temperature is raised to 950°C, roasted for 10 minutes, and finally cooled naturally to obtain the finished product. The water absorption rate of the produced ceramsite is ≤15%, and the bulk density range is ≤500kg / m 3 , Cylinder compressive strength ≥ 0.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com