Method for preparing polysilicon ferric sulfate water purifying agent from steel slag and water slag

A technology of iron water purifying agent and water slag, which is applied in the field of preparation of inorganic polymer flocculants, can solve the problems of high price and high cost, and achieve the effect of good effect and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

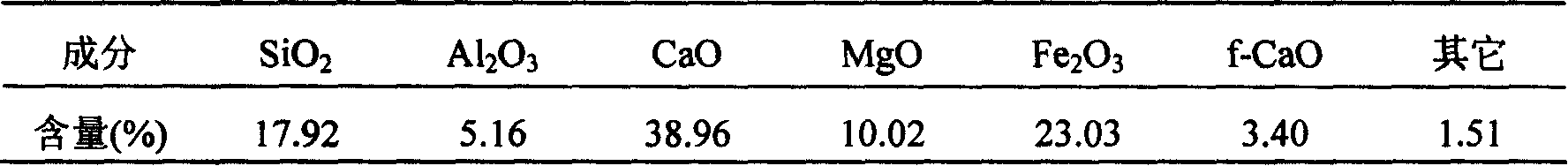

[0014] The steel slag and water slag used in the following examples are produced by Metallurgical Slag Company of Tangshan Iron and Steel Group, and their main chemical components are shown in Table 1 and Table 2 respectively.

[0015] Table 1 Main components of Tangshan steel slag

[0016]

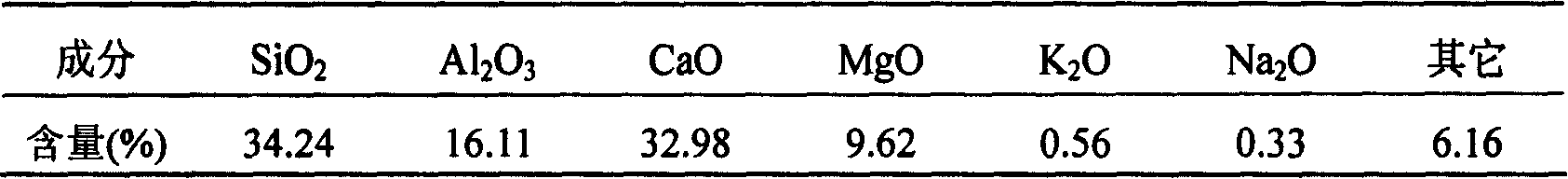

[0017] Table 2 The main components of Tangshan steel slag

[0018]

[0019] The method for preparing polysilicon ferric sulfate water purifying agent with it as raw material is as follows:

[0020] (1) Weigh 600g of steel slag, 400g of water slag, and 30g of natural quartz (where SiO 2 Content is 95.52%), after mixing, join in the reactor that is provided with agitator and reflux condensing device;

[0021] (2) adding 3000 g of sulfuric acid solution with a concentration of 10% into the above-mentioned reactor, stirring constantly, controlling the temperature at 120° C., and filtering after reflux reaction for 2.5 hours to obtain filtrate and filter residue;

[0022] (3) cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com