Method for determining melting temperature interval and melting behavior of metallurgical slag

A melting temperature, metallurgical slag technology, applied in the investigation phase/state change and other directions, can solve the problem that the slag melting behavior cannot be observed in real time in situ, the specific melting process of the slag sample cannot be observed, and the slag material loading process is demanding, etc. problem, to achieve the effect of convenient and practical operation, fast detection speed, and vivid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Accurate determination of melting temperature range of molten iron pretreatment dephosphorization slag and observation of melting behavior.

[0054] The present invention is applied in the measurement of the melting temperature range of the molten iron pretreatment dephosphorization slag and the observation of the melting behavior, and the specific steps are as follows:

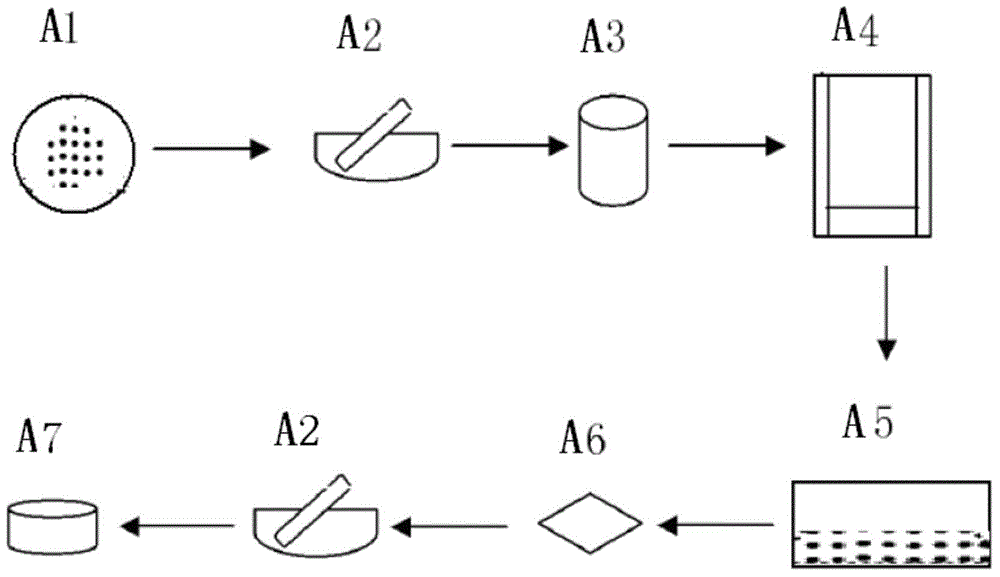

[0055] (1) Preparation of dephosphorization slag samples: Mix the molten iron pretreatment dephosphorization slag material in a mortar and put it in a graphite crucible, heat it in an induction furnace to about 1550°C to melt and keep it warm for 10 minutes for water quenching, after drying Grinding to make ≤100 mesh powder slag.

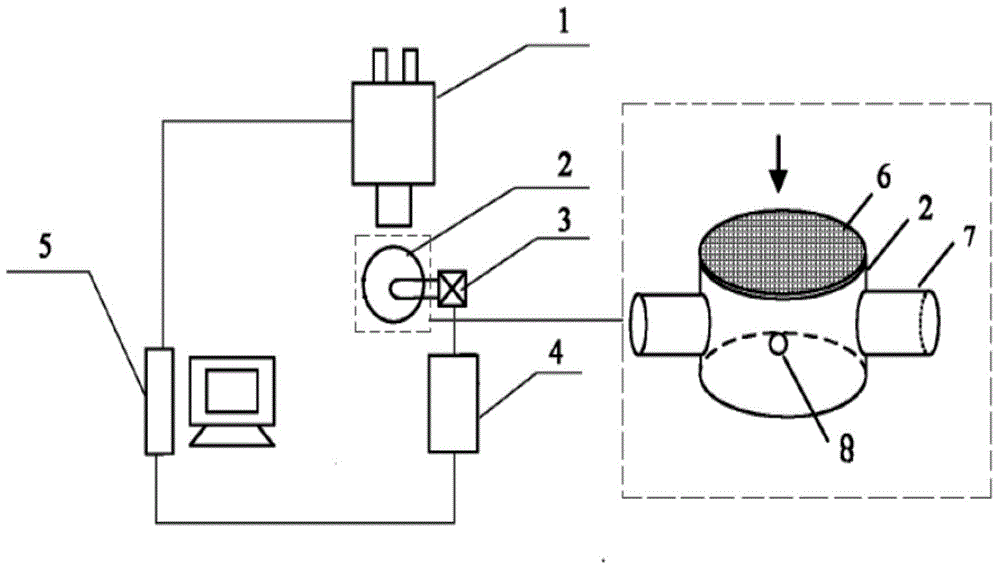

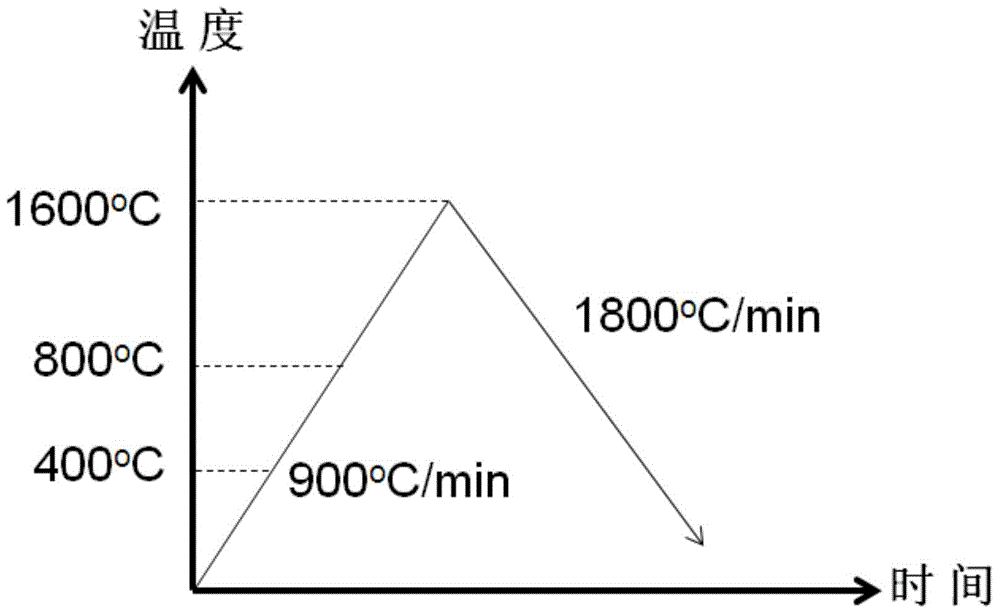

[0056] (2) Determination of loading powder samples: In manual mode, heat the thermocouple to about 580°C, lightly stick about 500 mg of dephosphorization slag sample, shake off the unsticky powder slag, and insert the thermocouple back into the reaction chamber for standby ...

Embodiment 2

[0063] Accurate determination of melting temperature range of continuous casting mold flux and observation of melting behavior.

[0064] The present invention is applied in the measurement of the melting temperature range of continuous casting mold flux and the observation of melting behavior, and the specific steps are as follows:

[0065] (1) Preparation of mold slag samples: Mix the continuous casting mold slag material in a mortar, put it in a graphite crucible, heat it to about 1500°C in an induction furnace, melt it and keep it warm for 10 minutes for water quenching, and grind it after drying. ≤100 mesh powder slag.

[0066] (2) Equip the powder sample: heat the thermocouple to about 520°C in manual mode, lightly stick about 500mg of mold powder slag sample, shake off the unsticky powder slag, and insert the thermocouple back into the reaction chamber for standby. After the temperature drops to room temperature, switch the manual mode to the automatic mode; then accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com