Safety injection pump operation life prediction method and system

A technology of operating life and prediction methods, applied in pump control, non-variable pumps, instruments, etc., can solve problems such as long cycle, high cost, and difficult life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

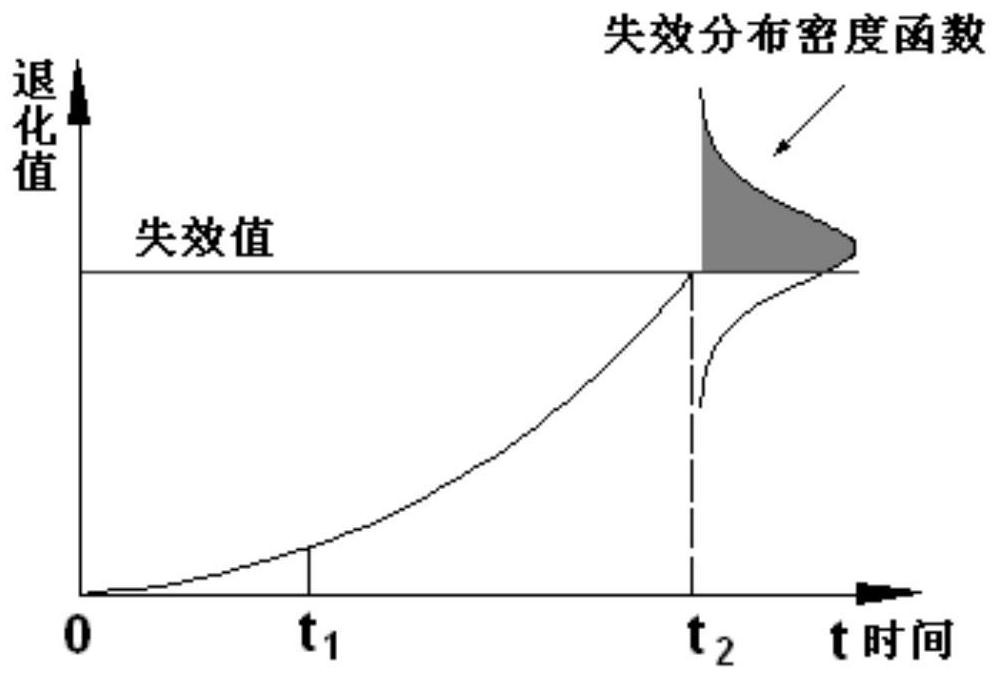

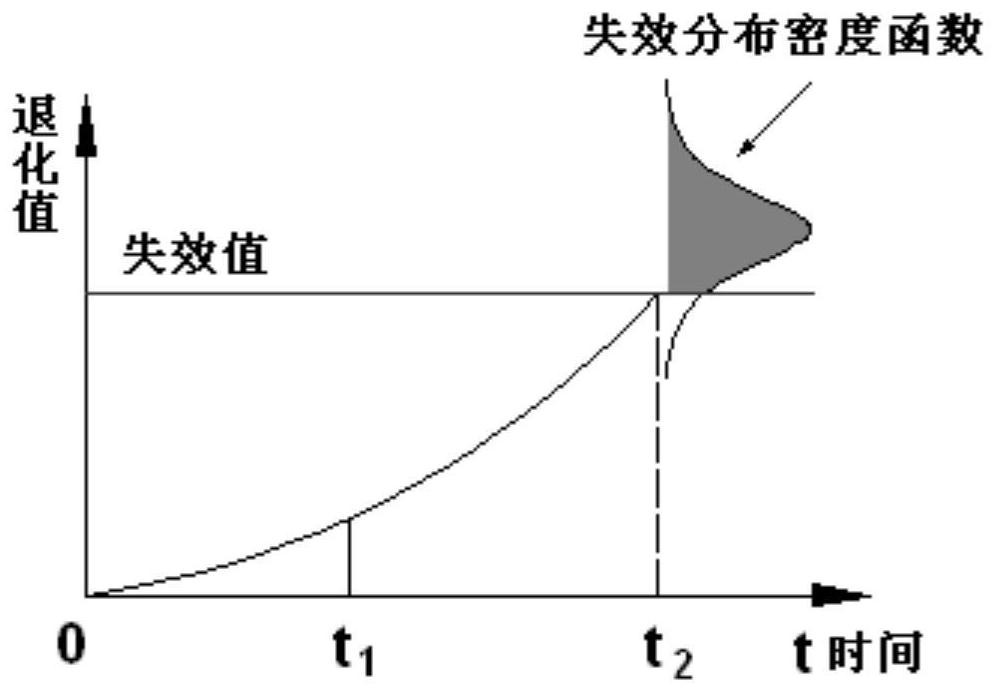

[0087] like figure 1 , Figure 2a , Figure 2b Shown:

[0088] A method for predicting the operating life of an injection pump, comprising the following steps:

[0089] S1. Carry out a performance test on the safety injection pump, and obtain the first set of test parameters and the first set of degradation characteristic parameters of the safety injection pump;

[0090] S2, according to the first set of test parameters, fit the function relationship of the test parameters of each performance test with time, and fit the function relationship of each degradation characteristic parameter of the performance test with time according to the first set of test parameters;

[0091] S3, construct the coupling relationship between the function relationship of each test parameter over time of the performance test and the function relationship of each degradation characteristic parameter over time of the performance test;

[0092] S4. Constructing a prediction model of the failure pro...

Embodiment 2

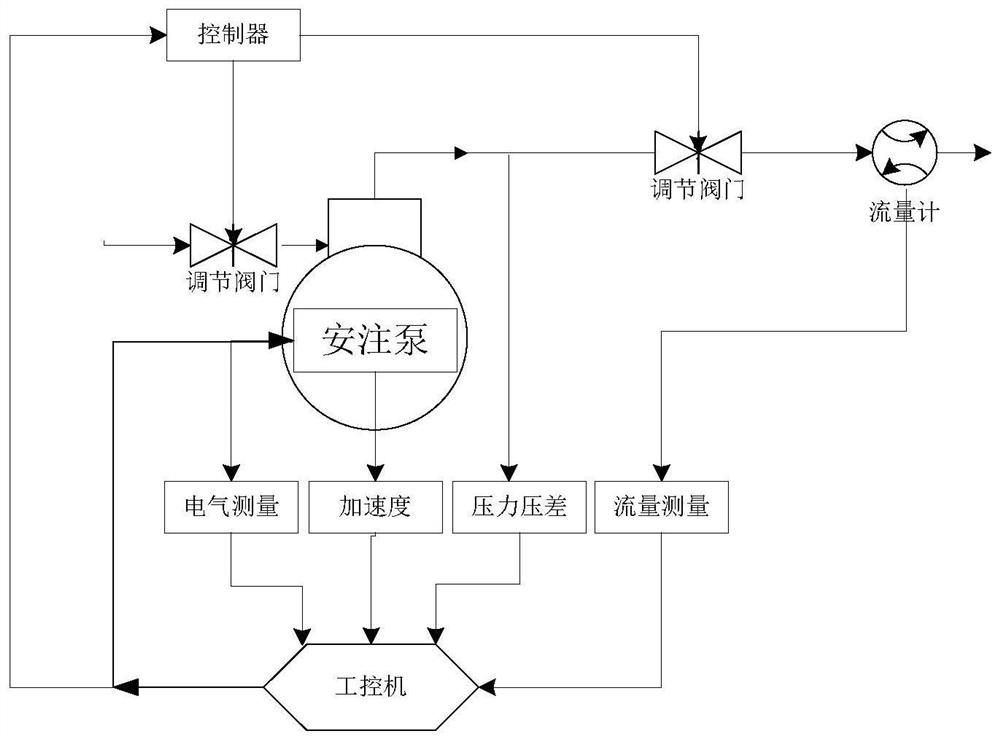

[0132] An injection pump operating life prediction system, including: a measurement system

[0133] The measurement system includes:

[0134] The inlet and outlet circuit of the safety injection pump is provided with an inlet regulating valve on the inlet of the safety injection pump, and an outlet regulating valve is arranged on the outlet of the safety injection pump.

[0135] The inlet regulating valve and the outlet regulating valve are controlled by the controller, and the controller is controlled by the instructions of the industrial computer;

[0136] An outlet pressure gauge, a differential pressure transmitter, and a flowmeter are installed on the outlet of the safety injection pump.

[0137] An accelerometer is installed on the injection pump body;

[0138] The safety injection pump is controlled by the electrical control of the industrial computer,

[0139] Also includes electrical measuring devices for measuring safety injection pumps;

[0140] Among them, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com