Test device applicable to ultralow temperature reinforcing steel bar tensile test

A test device and tensile test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as the failure to truly reflect the overall mechanical properties of the steel base material, the design of low-temperature fixtures, the difficulty of installation, and the small size of the fixtures. , to achieve the effect of rapid action, convenient operation and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

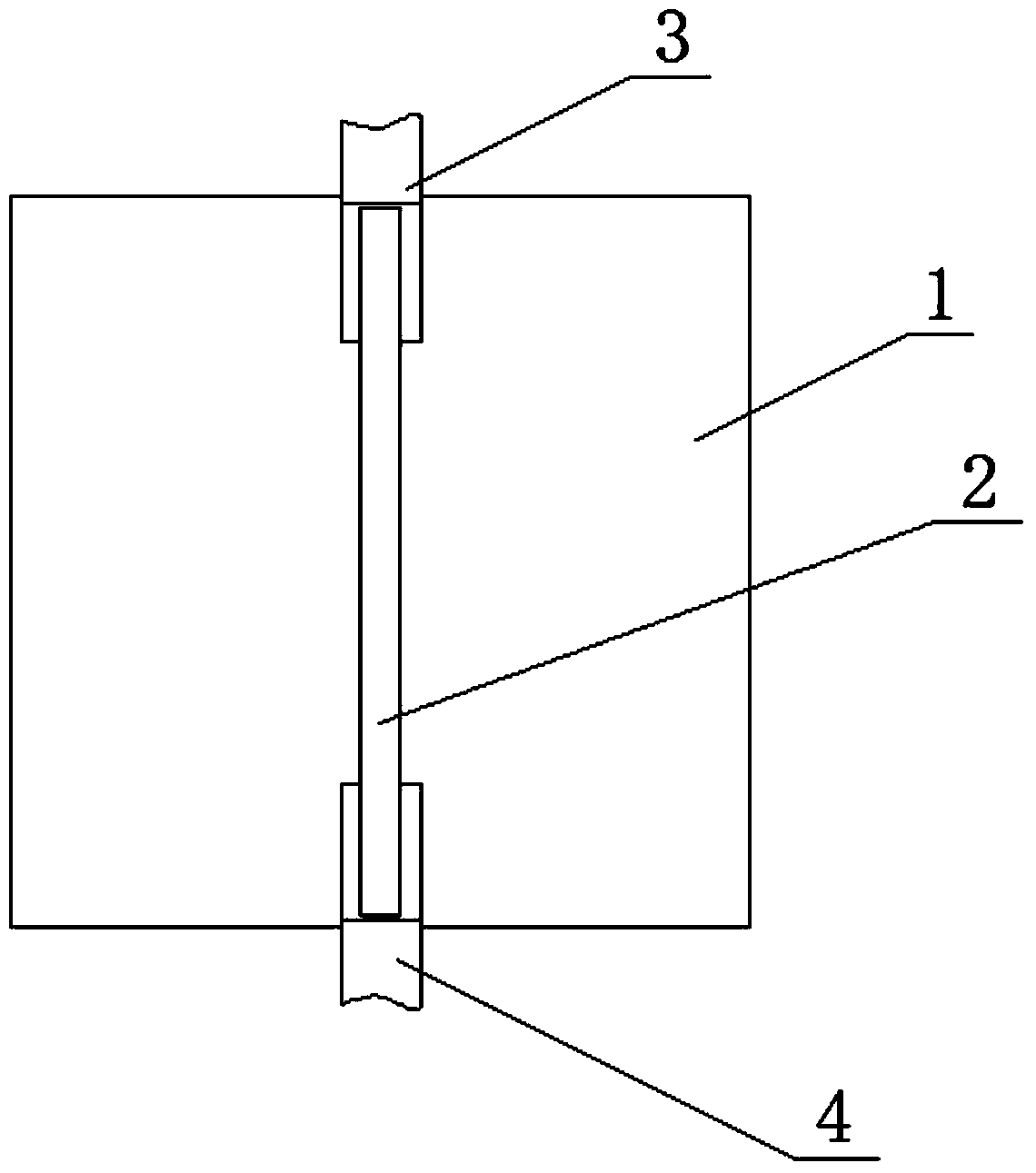

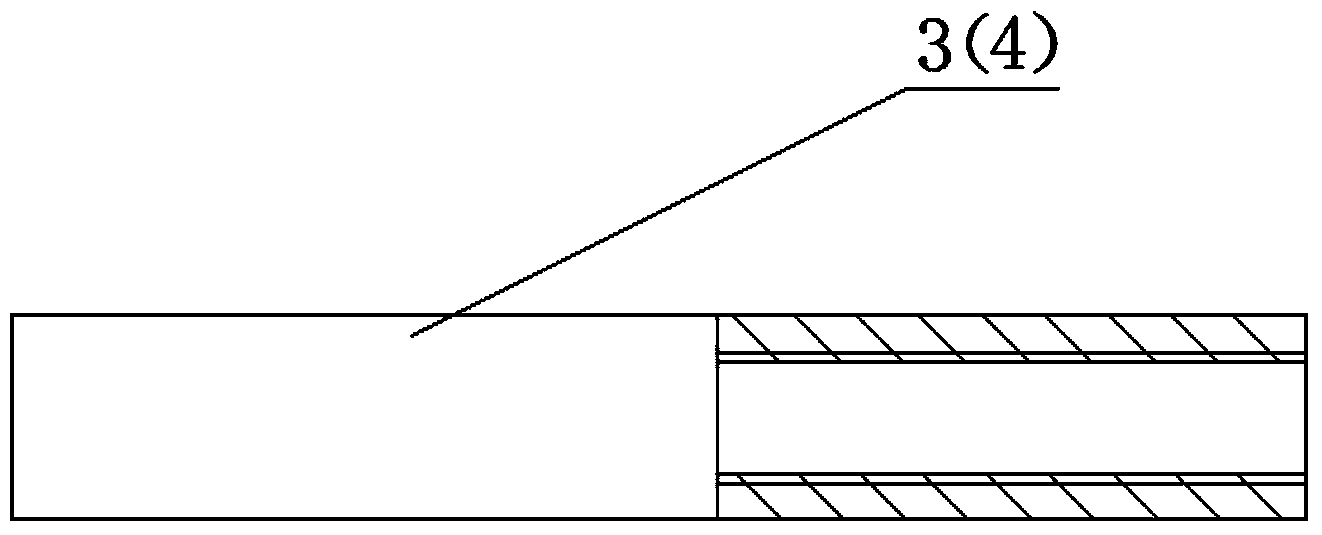

[0017] figure 1 It is a structural schematic diagram of a steel bar sample in the prior art, figure 2 It is a structural schematic diagram of the present invention, image 3 It is a schematic structural view of an upper threaded clamp and a lower threaded clamp in the present invention, Figure 4 It is a structural schematic diagram of a steel bar sample in the present invention. Depend on Figure 2-Figure 4 From the combination of the shown structures, it can be seen that the test device suitable for the ultra-low temperature steel bar tensile test includes a low temperature test chamber 1, a steel bar sample 2 and a fixture for fixing the steel bar sample 2 in the low temperature test box 1. The fixture includes an upper thread Fixture 3 and lower threaded fixture 4, upper threaded fixture 3 and lower threaded fixture 4 respectively connect one end of steel bar sample 2, and are fixed on the low temperature test chamber 1; Described upper threaded fixture 3 and lower thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com