Healing and leakage blocking performance evaluation method of self-healing gel leakage blocking material

A technology of plugging materials and evaluation methods, which can be used in the analysis of materials, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Effectively evaluate the performance of self-healing, less research and other issues, to achieve the effect of convenient calculation, reliable principle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for evaluating the healing plugging performance of a self-healing gel plugging material, the steps are as follows:

[0039] (1) Preparation of self-healing gel plugging system: Take 483.1g of polyvinyl alcohol, 290.1g of cationic cellulose, 3.3g of ferric chloride and 387.1g of acrylic acid, dissolve them in 6L of water, add 5.8g of ammonium persulfate and mix well, A self-healing gel plugging system is obtained. The obtained self-healing gel plugging system can be gelled at 50°C, and the gelation time is 3 hours.

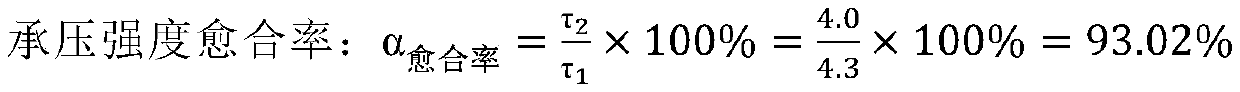

[0040]Bearing strength τ of self-healing gel plugging material 1 The test method is as follows: Take 5L of the above-mentioned self-healing gel plugging system and pour it into the mud tank of the high-temperature and high-pressure dynamic and static leakage instrument. The leakage at the outlet is relatively large; then raise the temperature to 50°C, no leakage after 3 hours, and the self-healing gel plugging system is gelled; slowly increase the...

Embodiment 2

[0054] A method for evaluating the healing plugging performance of a self-healing gel plugging material, the steps are as follows:

[0055] (1) Preparation of self-healing gel plugging system: Take 403.1g of polyvinyl alcohol, 268.5g of agar, 26.9g of ferric chloride and 201.8g of acrylic acid dissolved in 6L of water, add 13.4g of ammonium persulfate and mix evenly to obtain self-healing Combined gel plugging system; it can be gelled at 55°C, and the gelation time is 4 hours.

[0056] Bearing strength τ of self-healing gel plugging material 1 The test method is as follows: Take 5L of the above-mentioned self-healing gel plugging system and pour it into the mud tank of the high-temperature and high-pressure dynamic and static leakage instrument. The leakage at the outlet is relatively large; then raise the temperature to 55°C, no leakage after 4 hours, and the self-healing gel plugging system is gelled; slowly increase the pressure of the plugging instrument until a large amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com