Method for preparing inorganic slag fibers by using iron tailings

A technology of slag fiber and iron tailings, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of steel slag not being well utilized, comprehensive utilization rate of less than 10%, utilization rate of less than 20%, etc. Environmental benefits, ease of implementation, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

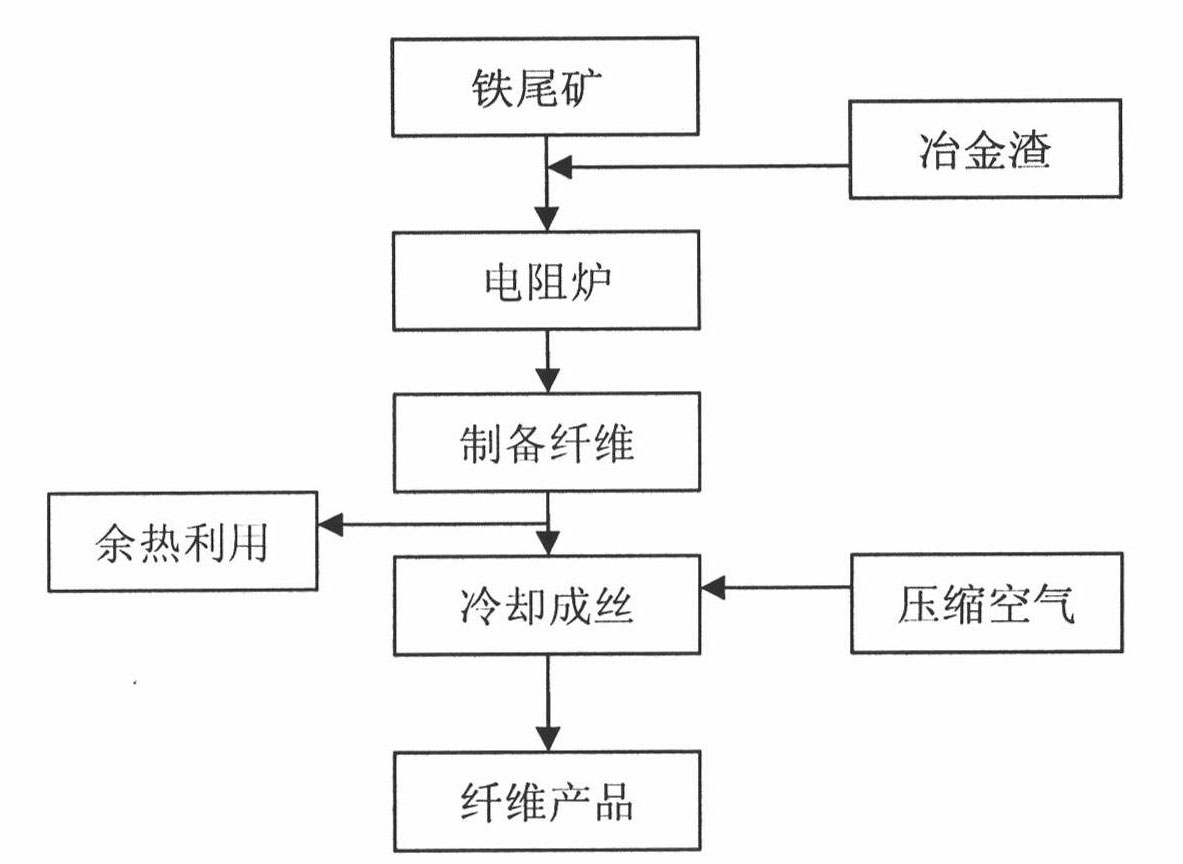

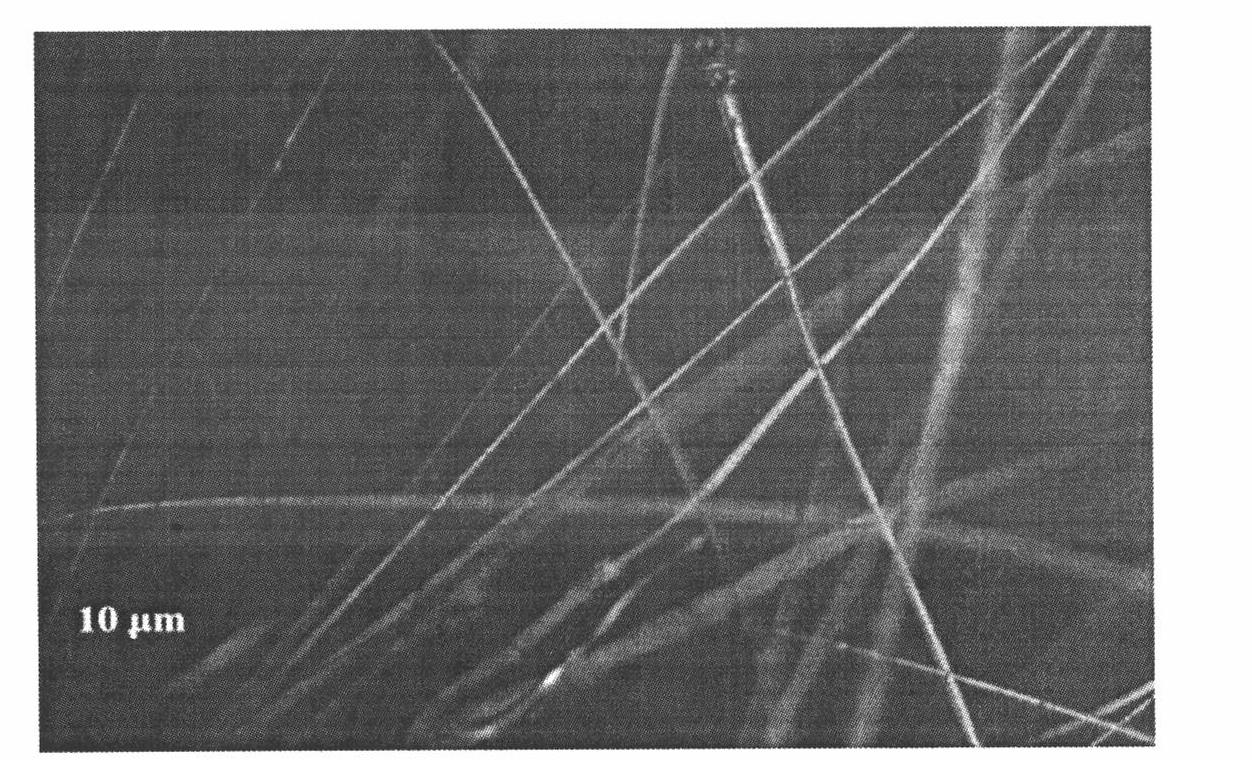

[0029] The weight percentage of iron tailings in the mixture is 70%, and blast furnace slag is 30%. Put the mixture into a melting resistance furnace with a temperature of 1600°C. After it is completely melted, let the molten liquid flow into the spinning machine. Under the action of the centrifugal force of the spinning roller, inorganic fibers of different lengths are obtained according to different linear speeds. Simultaneously spray compressed air to cool the obtained inorganic slag fiber filaments, such as figure 2 shown.

Embodiment 2

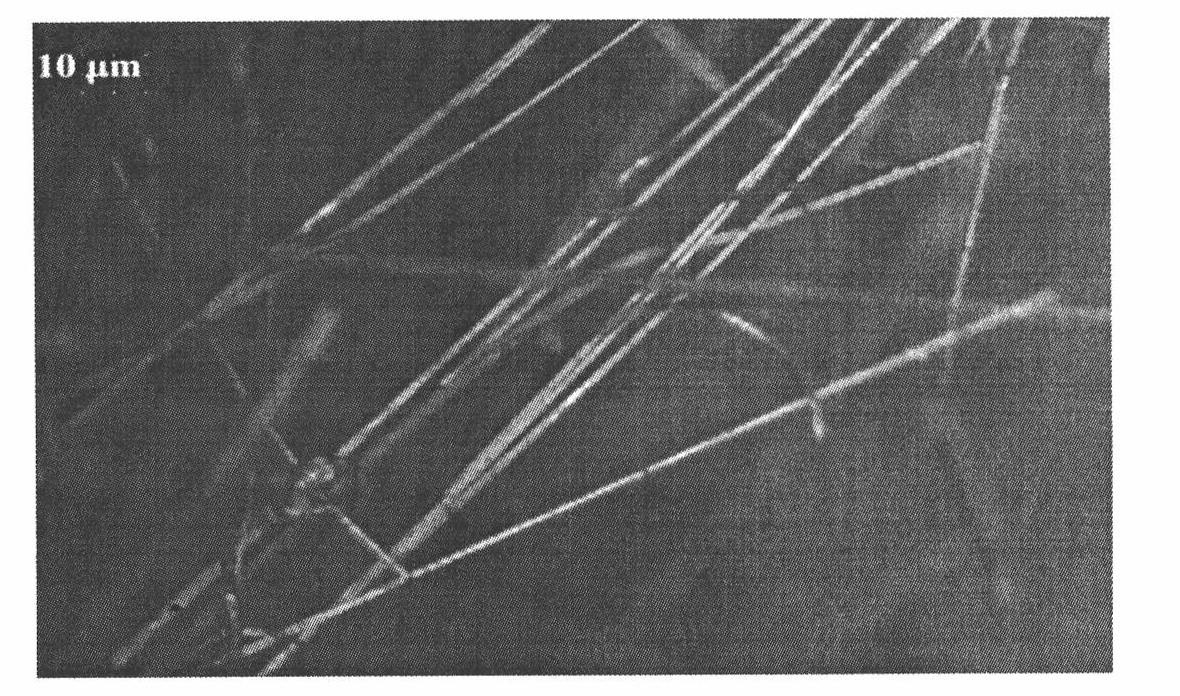

[0031] Adopt the same preparation method as Example 1, the difference is that the weight percentage of iron tailings in the mixture is 50%, and the inorganic slag fiber obtained at last is as image 3 shown.

Embodiment 3

[0033] Using the same preparation method as in Example 1, the difference is that the temperature of the melting resistance furnace is 1500° C., and a multi-hole spinneret is used to spray into filaments, and the inorganic slag mineral fibers are obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com