System and method for manufacturing mineral wool board or felt through hot slag

A hot slag, mineral wool board technology, applied in the direction of manufacturing tools, ceramic molding workshops, supply devices, etc., can solve the problem of small market capacity of finished products, reduce consumption and environmental pollution, large utilization, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

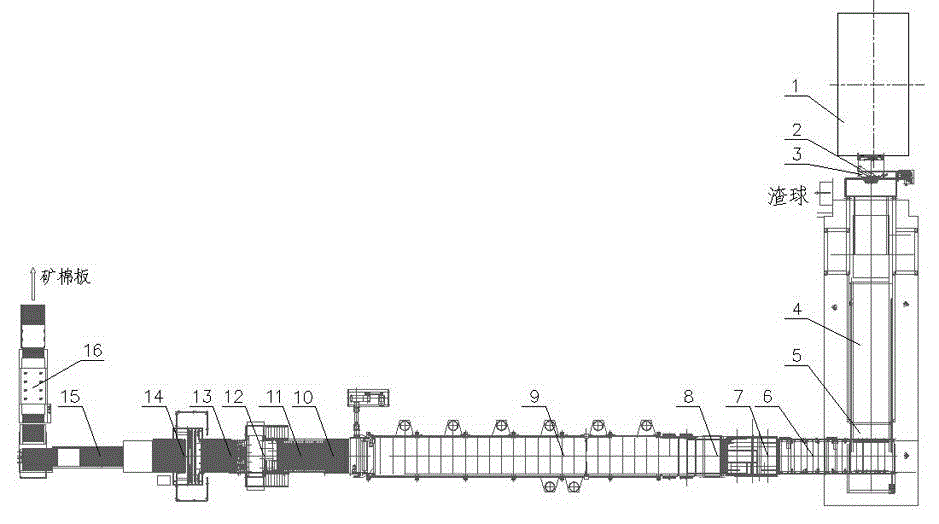

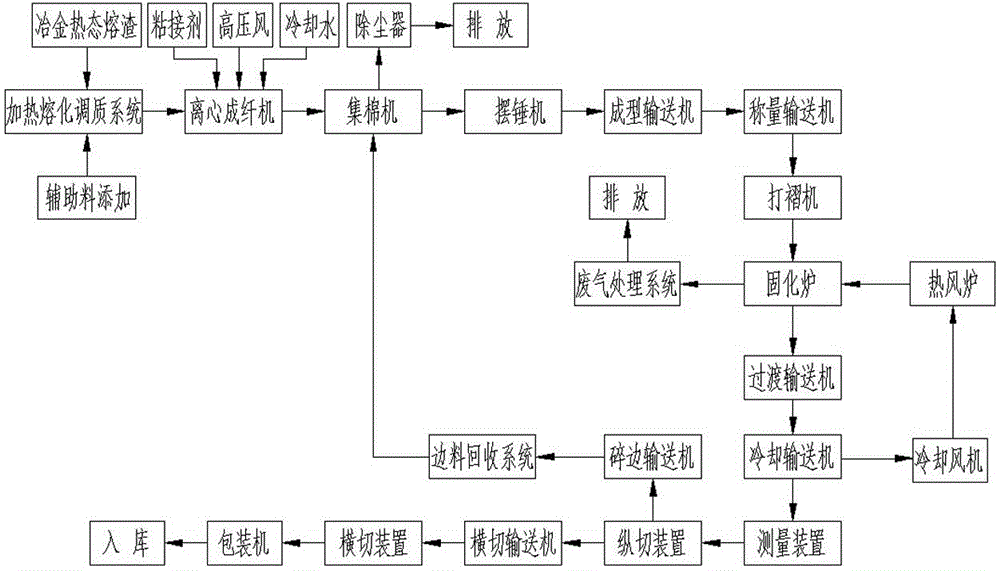

[0052] See figure 1 with figure 2 In the system and method for preparing mineral wool board or felt by using hot slag provided in this embodiment, metallurgical hot slag (such as blast furnace slag, steel slag, ferroalloy slag, etc.) Directly flow into the heating and melting conditioning system through the slag ditch, or pour into the heating and melting conditioning system through the tank, and preferably add auxiliary materials (conditioning and tempering materials or conditioning materials and fluxing materials), and pass the auxiliary materials through a matching upper The material system is added to the heating, melting and tempering system; the heating, melting and tempering system controls the temperature at 1450°C-1600°C, the holding time is 6-24 hours, and at the same time combines methods such as adding an appropriate amount of auxiliary materials to make the slag tempered and tempered. Qualified melt of mineral wool board.

[0053] See figure 1 , the system of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com