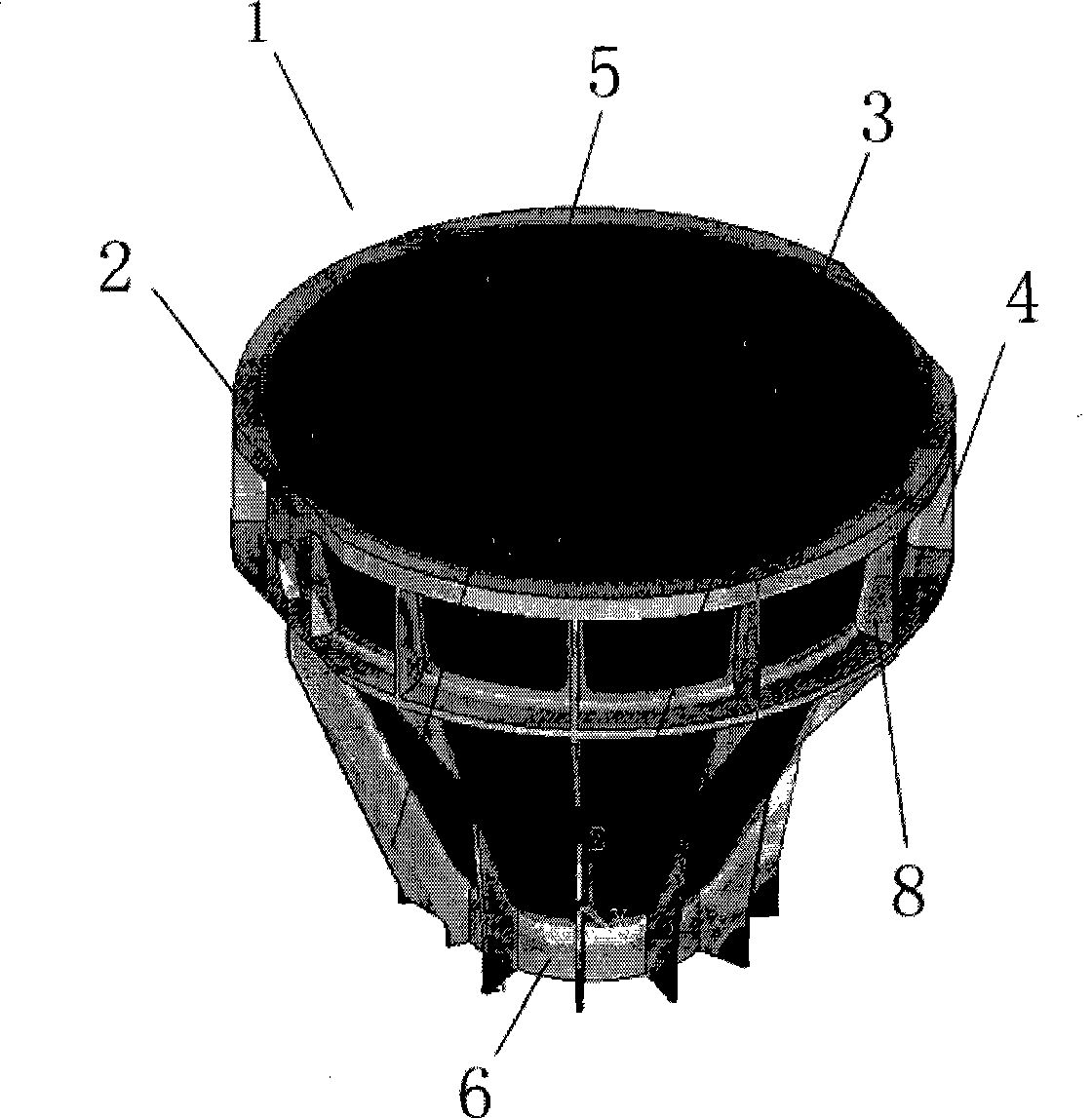

Novel structured metallurgy cinder ladle and method of producing the same

A new type of structure and manufacturing method technology, applied in the field of metallurgy, can solve problems such as poor repairability, unfavorable cost reduction and efficiency increase, and affect performance, so as to achieve good weldability and repairability, reduce environmental pollution, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

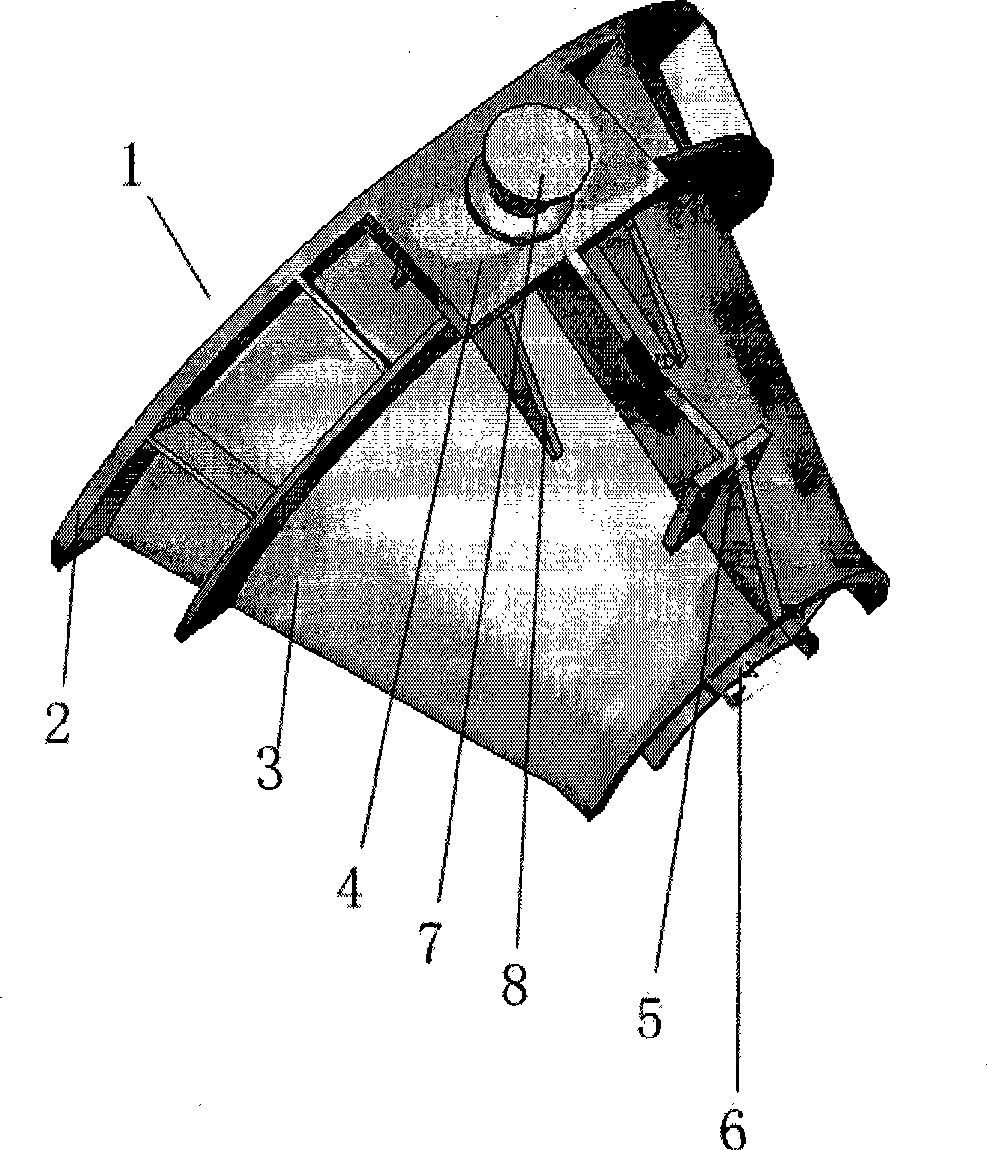

[0064] (1) Material selection or material selection: Choose 3-8 wide and thick alloy steel plates such as carbon steel or low alloy steel such as 16Mn (Q345B, C, D), SM490 (B, C). The thickness of the steel plate ranges from 40mm to 80mm.

[0065] (2) Blanking and groove processing: "X" grooves are used for the welding of the thick plate of the tank body, the reinforcement flange of the mouth, the main plate of the overturned force-bearing part, and the longitudinal main rib plate of the trunnion force-bearing area. The groove of the bottom plate of the base adopts "K" type, and the other adopts unilateral "V" groove. Groove angle 35°~55°. Cutting by flame plus mechanical method (automatic).

[0066] (3) Steel plate pressing (rolling): Adopt normal temperature cold working pressing method.

[0067] (4) Tank (cylinder) welding: automatic submerged arc welding is adopted. Use H08Mn, H08MnA, H10Mn2 or H08Mn2Si etc. for welding wire. Manual CO2 gas shielded welding can also b...

Embodiment 2

[0091] Except following, other is the same as embodiment 1, and its volume of the present invention is made respectively the slag tank etc. of 5.3 cubic meters, 15 cubic meters, 18 cubic meters to 33 cubic meters.

[0092] Material selection or material selection: choose 8-12 wide and thick carbon steel plates such as 20g, 20#, and 25#. It is formed by rolling or rolling forming. The steel plate thickness ranges from 80mm to 120mm; tank body welding: automatic electroslag welding; the metallurgical slag tank with the new structure adopts a tank wall inclination with a slope (α) in the range of 75°-55°. The bottom of the tank adopts a "arc bottom" structure, that is, a concave arc-shaped steel plate is used as the slag tank base and the steel plate as the tank wall is welded together, and a reinforcing rib plate is welded at the lower part of the concave arc-shaped slag tank base.

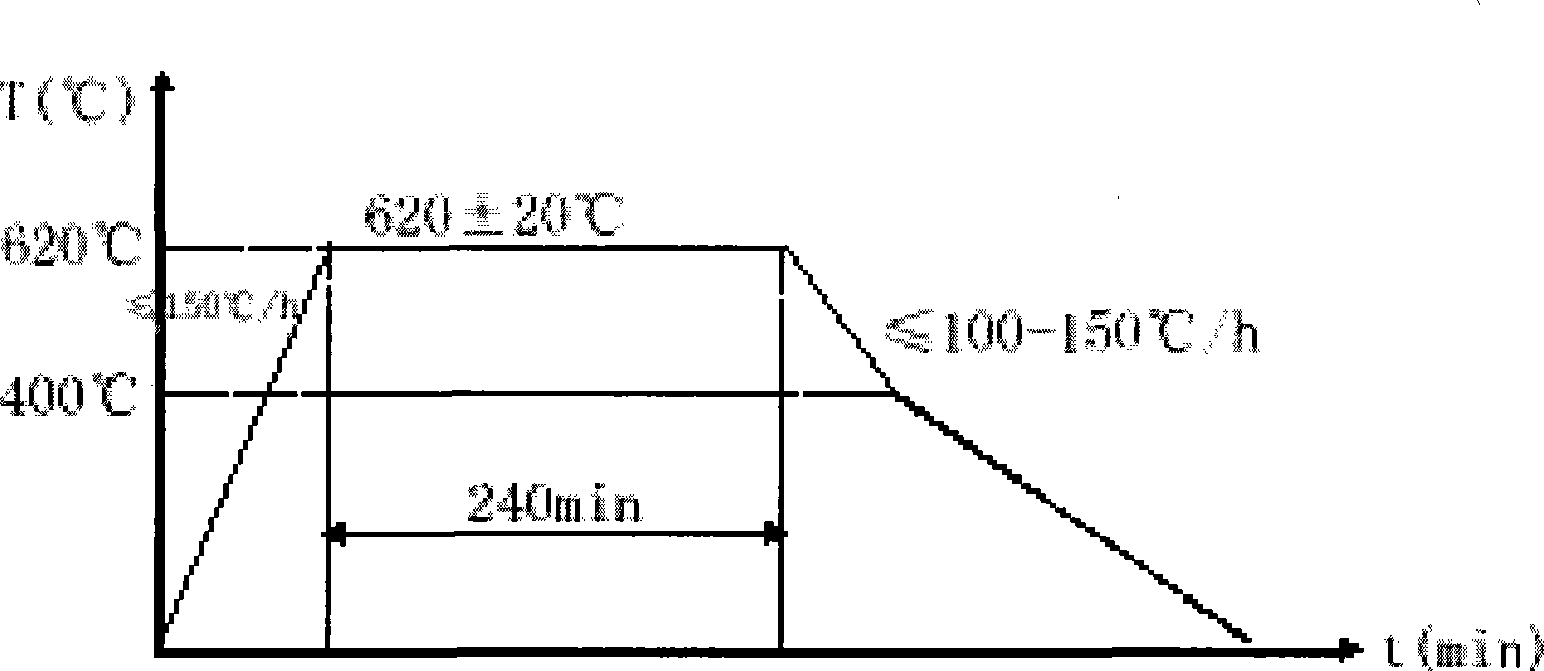

[0093]Cooling rate: 90-120°C / h; In addition to the outer peripheral edge of the tank mouth, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com