Carbon determination method for converter steelmaking flue gas analysis

A flue gas analysis and converter steelmaking technology, applied in the field of iron and steel metallurgy, can solve the problems that are difficult to accurately determine, and the influence of the decarburization rate of the converter bath is not considered, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

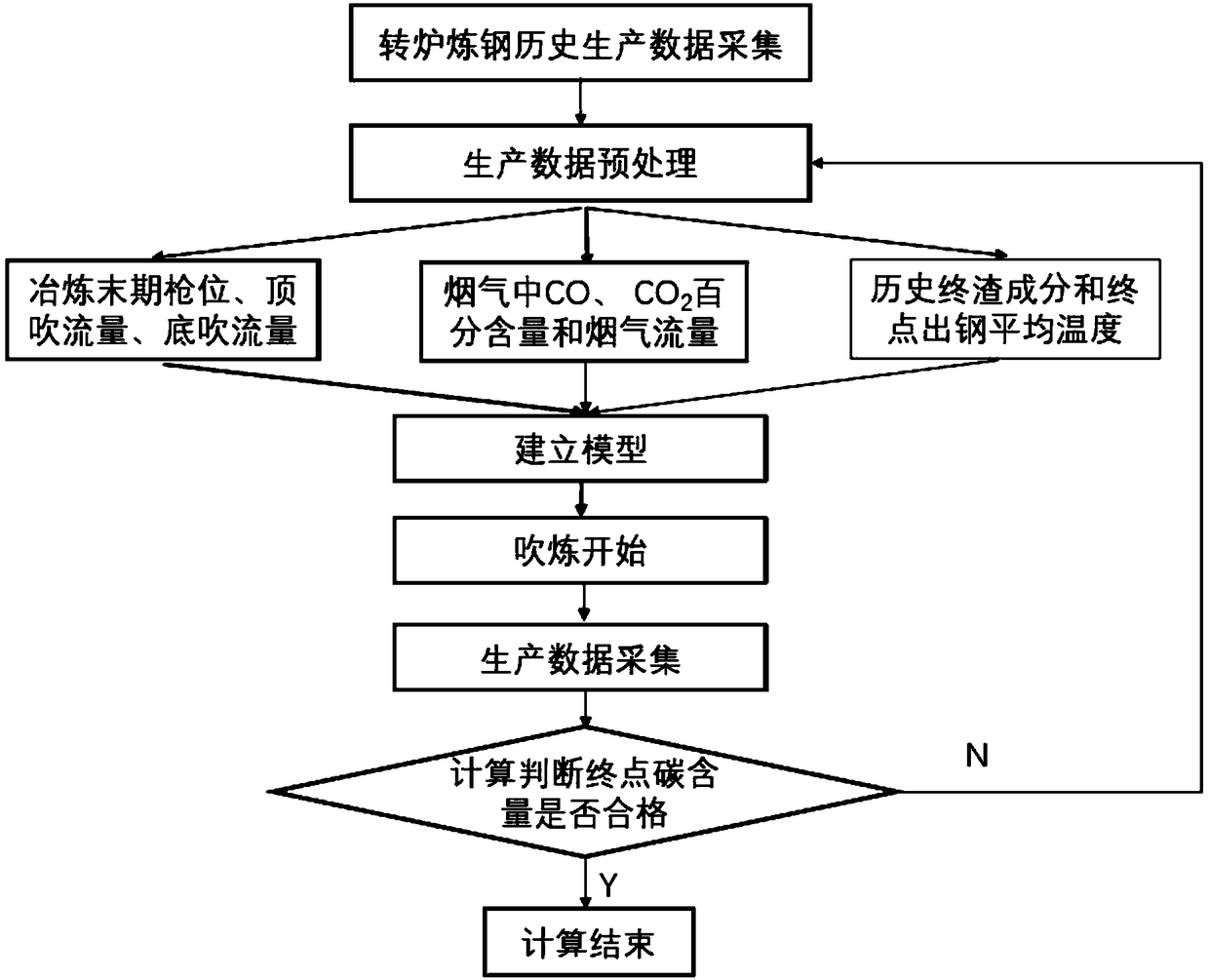

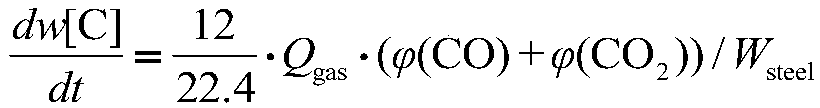

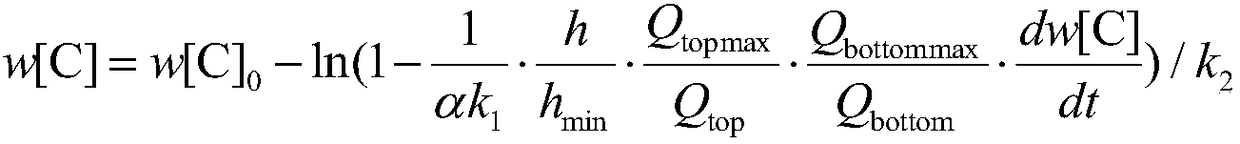

Method used

Image

Examples

specific Embodiment

[0058] When the 210-ton converter of a steel plant produces SPHC steel as the implementation carrier, when the converter blowing is close to the end, the oxygen lance position, top blowing oxygen flow rate, bottom blowing gas flow rate, flue gas CO and CO are obtained through the detection equipment. 2 According to the percentage content and flue gas flow rate, according to the molecular theory of metallurgical slag and historical data, the activity of FeO in the slag is calculated to be 0.241. When the average tapping temperature is 1686°C, the limit carbon content w[C] of the molten pool for the selective oxidation of C and Fe elements 0 is 0.033%. Table 1 is the final slag composition of SPHC steel, and Table 2 is the experimental results after the implementation of the present invention. From the experimental results, the prediction error of the carbon content at the end of converter smelting provided by the model has a high hit rate when the error is between ±0.02%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com