Anhydrous granulating technique of metallurgical slag or melted sulphonium and device thereof

A technology of metallurgical slag and chemical equipment, applied in the field of pyrometallurgy, which can solve the problems of environmental pollution, deterioration of water system water quality, high operation and maintenance costs, and achieve the effects of convenient operation, low investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

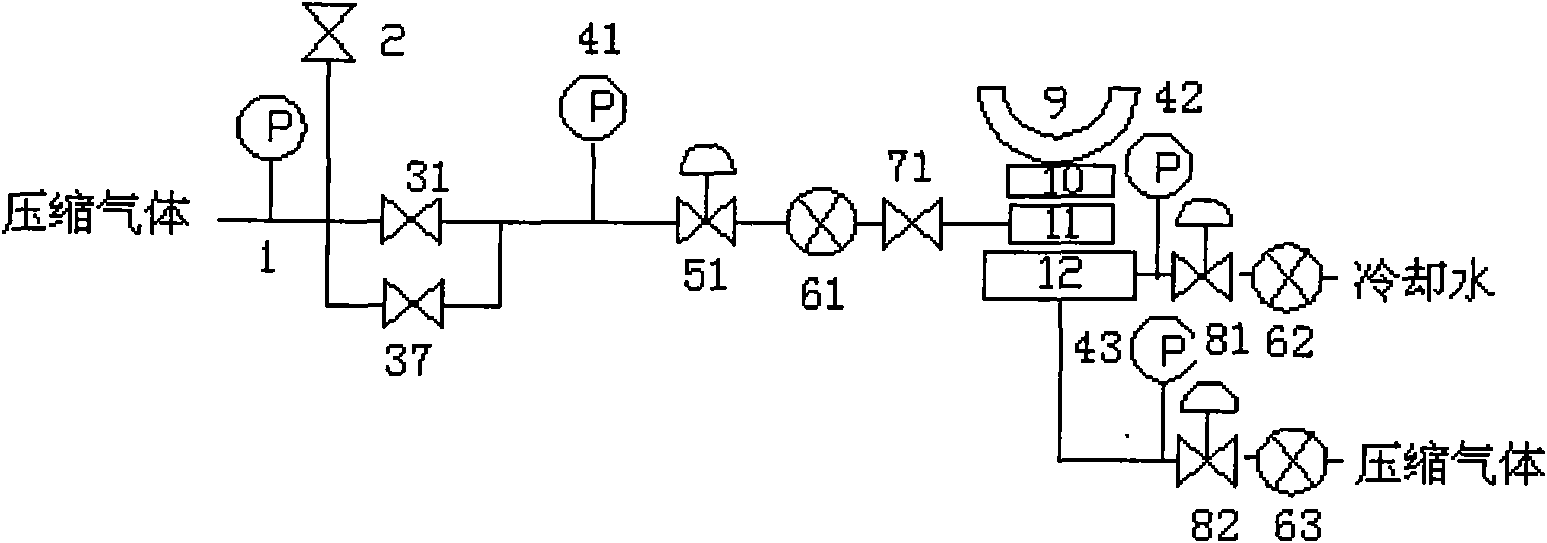

[0018] figure 1 It is a structural schematic diagram of anhydrous granulation device for metallurgical slag or molten matte of the present invention, which is applied to existing metallurgical furnaces, such as figure 1 As shown, the present invention includes a granulation chamber (not shown in the figure), a dispersion device 11 and a cooling water nozzle 12 .

[0019] The inner cavity of the granulation chamber communicates with the slag discharge chute 9, the bottom slag discharge port is opposite to the feed bin (not shown in the figure), and the top is provided with an emptying chimney and an induced draft fan.

[0020] The dispersing device 11 is a dispersing nozzle, which is installed in the granulation chamber and below the outlet of the slag chute 9, which is inclined upwards towards the molten slag flow and has an angle of 0-60° with the horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com