Multilayer coaxial rotating sieve

A rotary screen and coaxial technology, applied in the field of rotary screens, can solve the problems of high noise, small screening area, and low screening efficiency in grading and screening, and achieve easy maintenance and replacement, improved sorting efficiency, and avoid repeated screening score effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

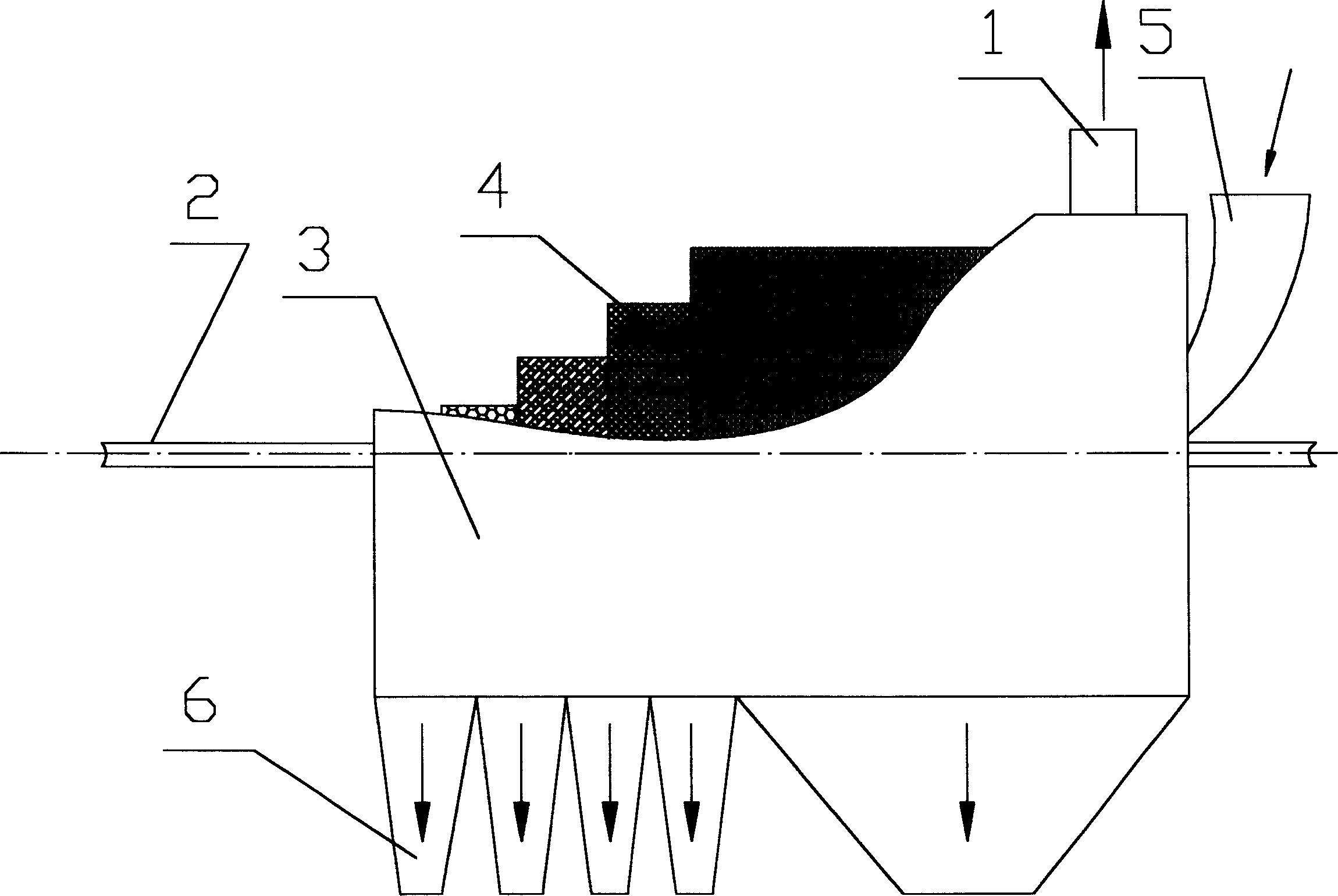

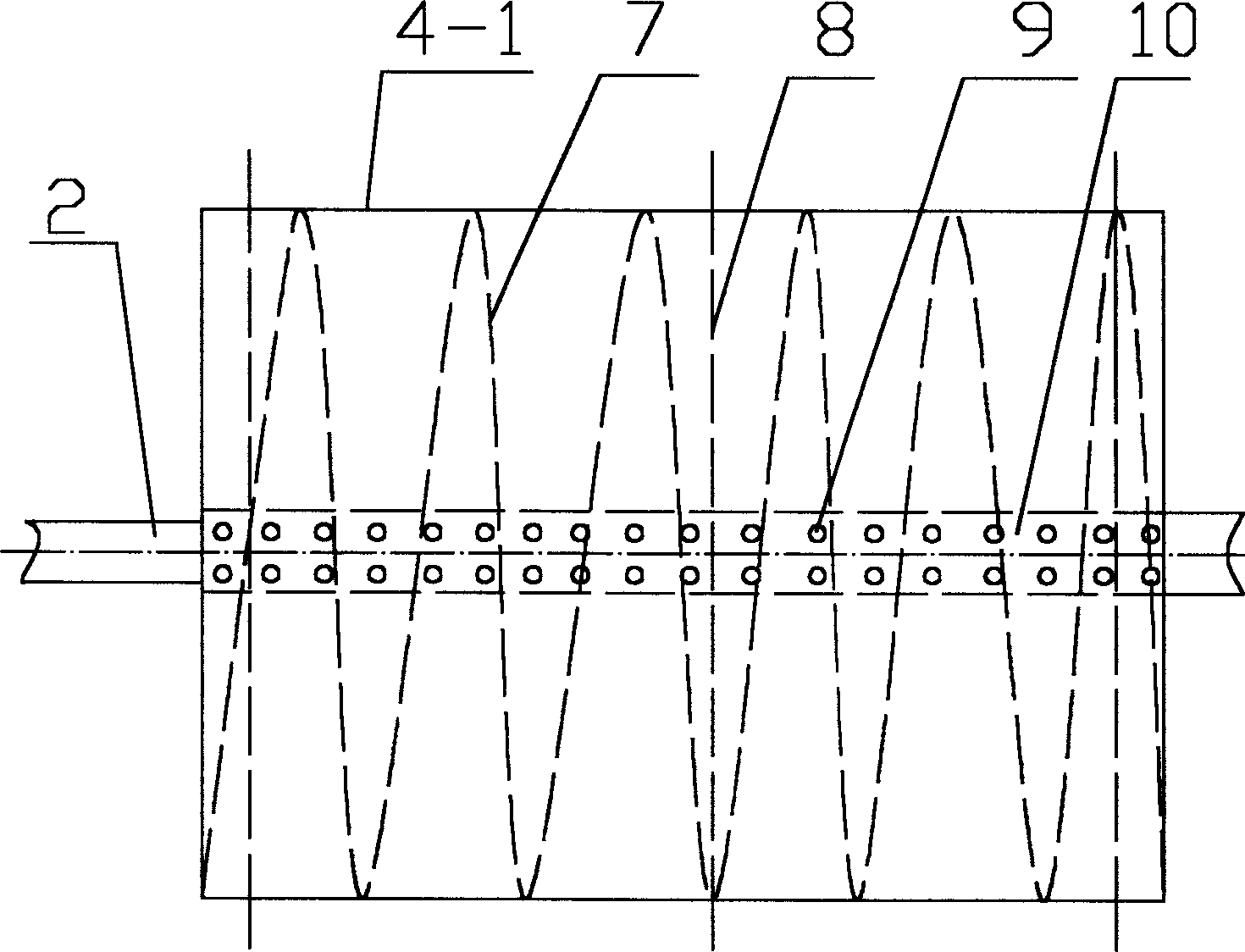

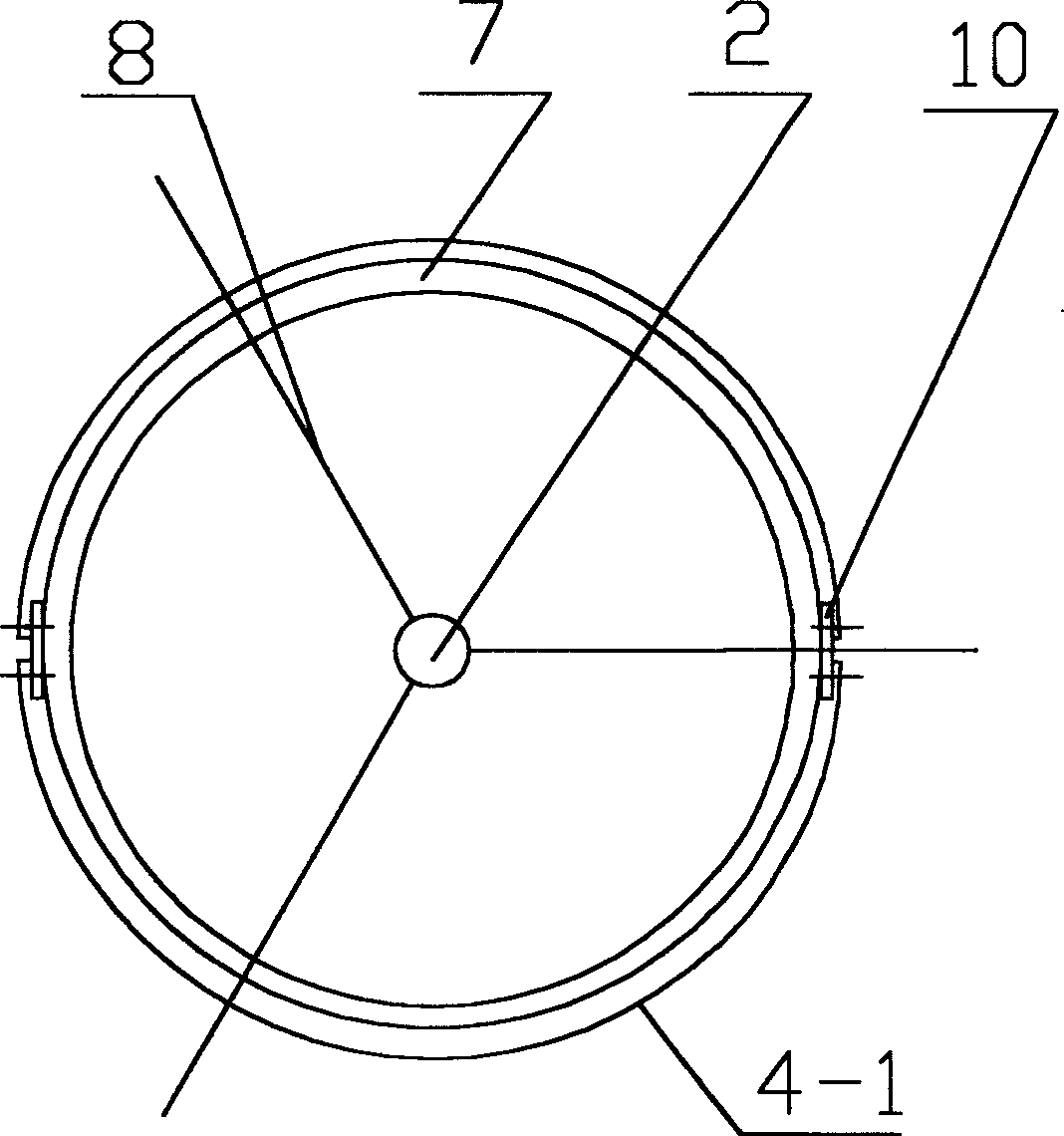

[0020] Such as figure 1 , 2 , a kind of multi-layer coaxial rotary screen shown in 3, comprises shell barrel body 3, feed inlet 5, discharge port 6, screen cloth and its rotating shaft 2, and the screen cloth that is arranged in shell barrel body 3 It is a multi-layer cylindrical screen 4 that revolves around the same rotating shaft 2. The top of one end of the shell barrel 3 is provided with a feed port 5 corresponding to the innermost screen 4-1, and the other end of the shell barrel 3 Or its bottom is respectively provided with a plurality of outlets 6 corresponding to the screen layer, and the sieve hole of each layer of screen expands from inside to outside with the diameter of each layer of screen from large to small, and each layer of screen A screw propulsion plate 7 matching the diameter of the screen frame is provided inside, and the screens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com