Method for recycling ammine in ammonium paratungstate production

A technology for the recovery of ammonium paratungstate and ammonia, applied in the field of ammonia recovery, can solve the problems of increasing ammonia wastewater treatment links, low concentration of ammonia water, environmental pollution, etc., and achieve the effects of reducing production costs, preventing air pollution, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

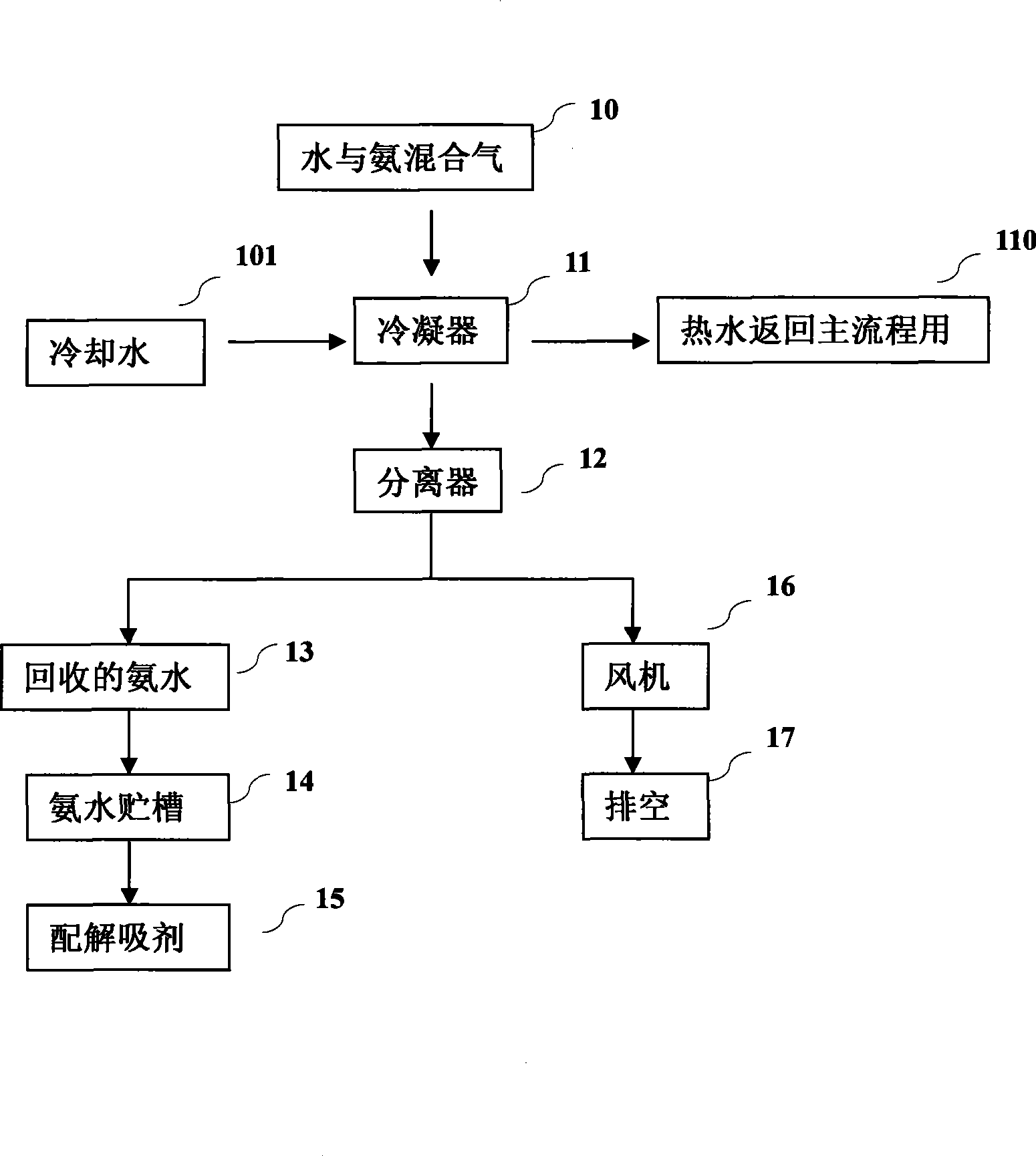

[0013] The present invention will be described in detail below in conjunction with the drawings, principles of the present invention and process steps.

[0014] During the evaporative crystallization process of ammonium paratungstate, the free ammonia in the crystallization pot solution and the ammonia and water vapor released during the crystallization process volatilize in gaseous form. The reaction equation is as follows:

[0015] h 2 O(lq)=H 2 O(g)

[0016] NH 3 h 2 O(lq)=NH 3 (g)+H 2 O(lq)

[0017] 12(NH 4 ) 2 WO 4 (lq)=5(NH 4 ) 2 O12WO 3 (s)+NH 3 (g)+H 2 O(lq)

[0018] The inventive method comprises the following steps:

[0019] Start the fan 16 to make the pipeline connected to the upper end of the closed crystallization pot body generate negative pressure for vacuum collection, so that the vacuum degree in the closed crystallization pot body is controlled at 10.0 to 14.0kPa, and the evaporated water and ammonia mixed gas 10 is sucked into the pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com