Method and apparatus for gaseous mixing in a diesel exhaust system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

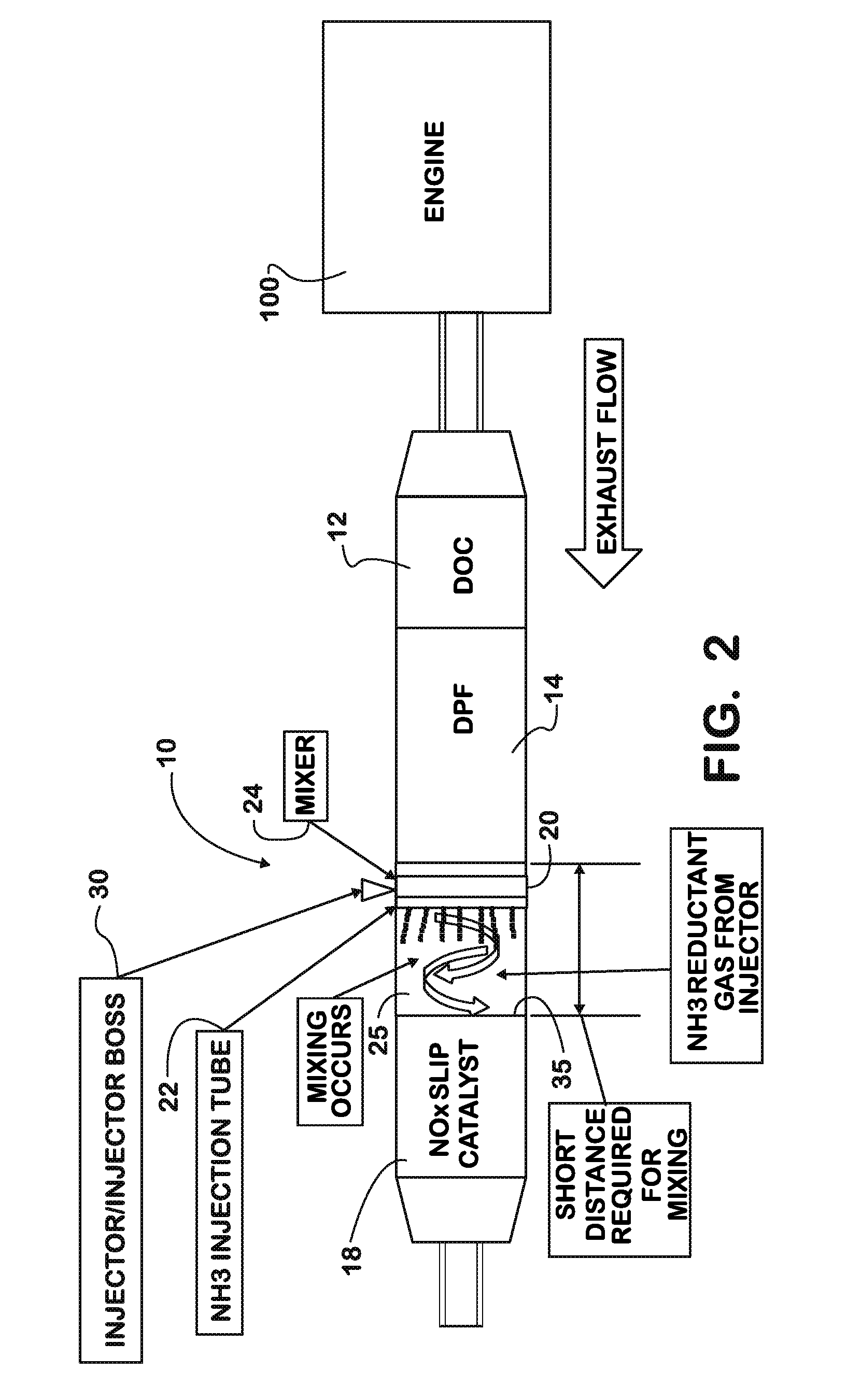

[0018]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail a preferred embodiment of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to embodiments illustrated.

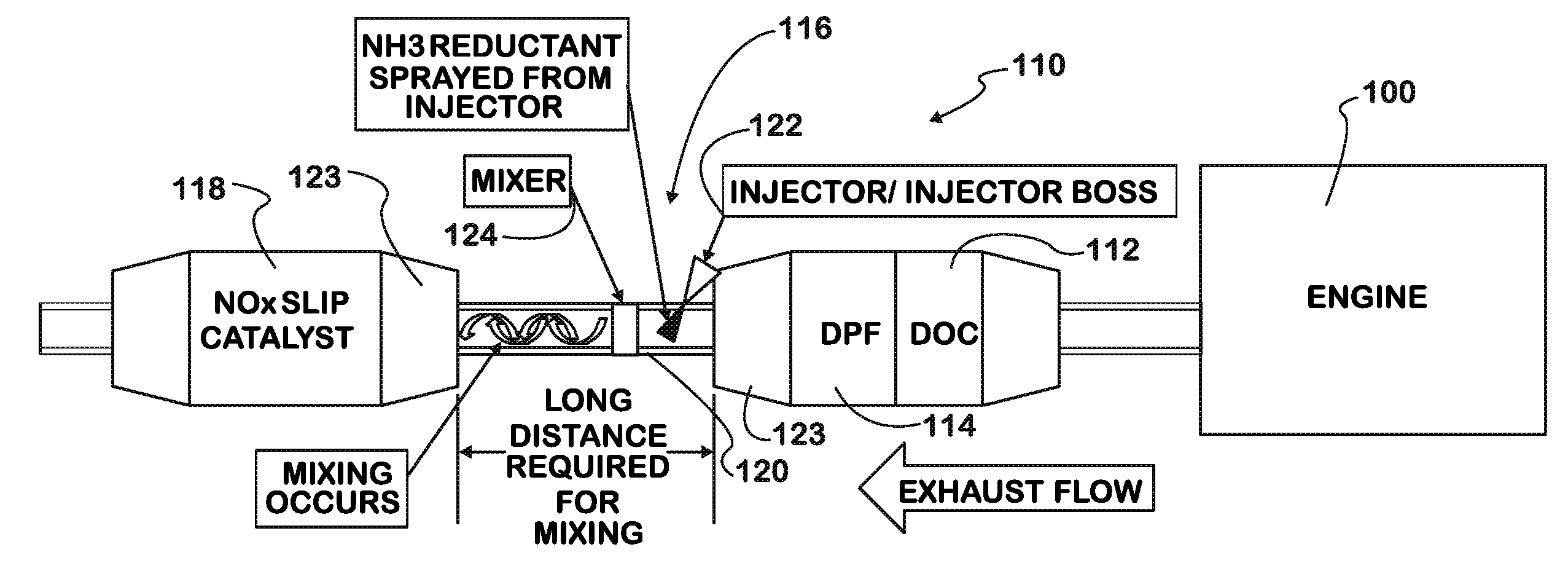

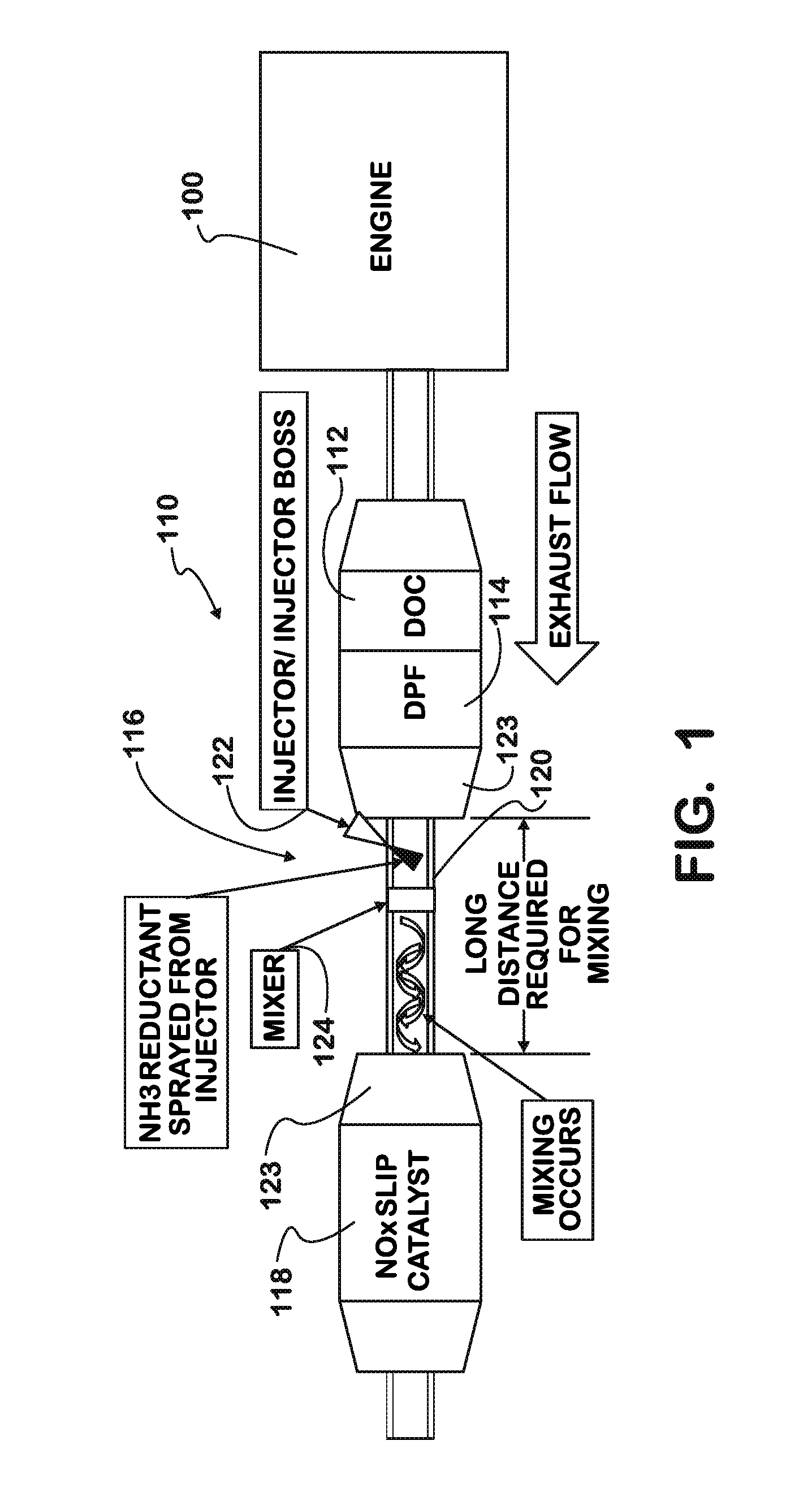

[0019]Referring to FIG. 1, there is illustrated a typical mixer / injector device. Exhaust is discharged from the diesel engine 100, through conduit such as exhaust piping to an exhaust treatment system 110. The exhaust treatment system 110 typically consists of, in downstream order, a diesel oxidation catalyst (DOC) 112, a diesel particulate filter (DPF) 114, a mixer / NH3 treatment canister 116, and a NOx slip catalyst (NSC) 118. The DOC 112, DPF 114 and NSC 118 are additional exhaust treatment structures present in most diesel exhaust treatment systems and which form no part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Homogeneity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com