Fluoroplastic or elastic body insulation chlorinated polyethylene jacket feeding and signal cable

A technology of chlorinated polyethylene and signal cables, applied in the direction of insulated cables, insulated conductors, flexible cables, etc., can solve the problems of not being resistant to wear, not being able to withstand bending, and not being able to adapt to the needs of special vehicle operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

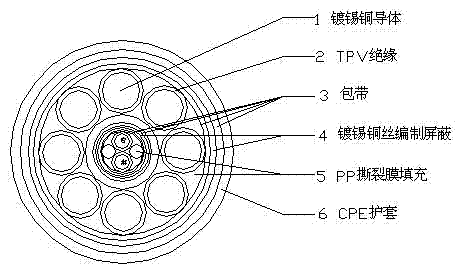

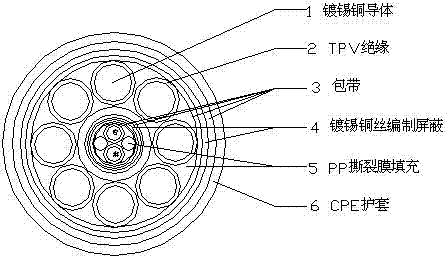

[0015] Such as figure 1 Shown: the cable core of a wear-resistant, fluorine plastic or elastomer insulated chlorinated polyethylene sheathed power supply and signal cable of the present invention is composed of a communication and power core, that is, a tinned copper conductor 1. The communication core is composed of an insulated wire core made of extruded TPV insulation 2 material. The insulating core core is twisted and wrapped with a layer of polyester film, that is, the tape 3, and the insulating tinned copper wire braided shielding layer 4 is wrapped outside the tape 3 , Tinned copper wire braided shielding layer 4 is wrapped with a layer of non-woven fabric as a protective layer, 6 power cores are concentrically twisted around the communication core, and the gap is filled with PP tear tape 5, outside the twisted cable core Two layers of wrapping tape 3 are wrapped around the wrapping tape 3, and a tinned copper wire braided shielding layer 4 is braided outside the wrapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com