Flat-shaped power cable connected through frame

A power cable and flat technology, which is applied in the field of flat power cables, can solve the problems of affecting the performance of the cable, poor compressive mechanical performance, brittle cracking, etc., to achieve simple and practical structural improvement, improve compressive mechanical performance, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

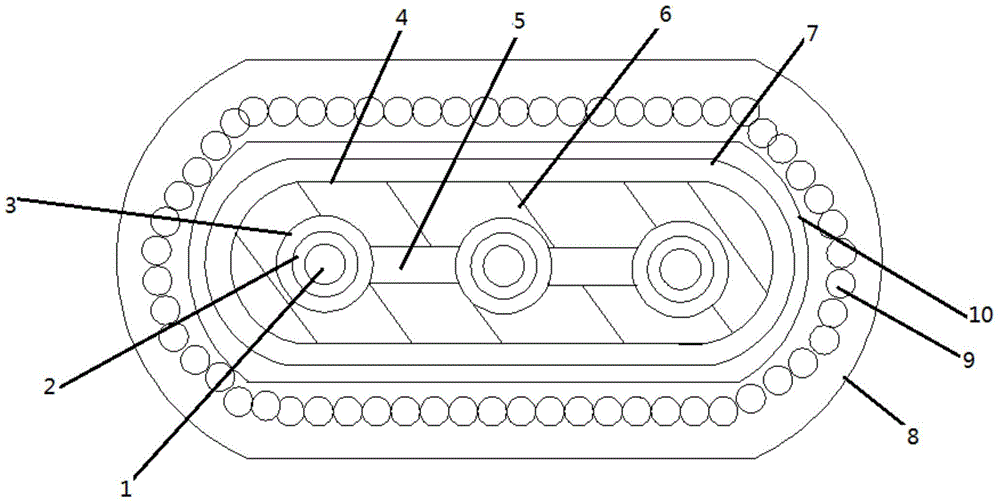

[0015] see figure 1 , a skeleton-connected flat power cable, comprising a plurality of conductors 1, the plurality of conductors 1 are horizontally arranged side by side, and the outer surfaces of the plurality of conductors 1 are respectively coated with polyethylene insulating layers 2, low-smoke and no-smoke The outer wrapping layer 3 of the halogen flame-retardant tape, the outer wrapping layer 3 of the low-smoke and halogen-free flame-retardant tape of the plurality of wires is jointly covered with the inner sheath layer 4 of the flat structure, and the inner sheath layer of the flat structure The layer 4 is provided with a rubber skeleton 5, and the rubber skeleton 5 connects the adjacent wires 1 together; the outer wrapping layer 3 of the low-smoke halogen-free flame-retardant tape of the flat structure is filled with high-temperature-resistant fiber filaments 6 , the low-smoke halogen-free flame-retardant tape of the flat structure is wrapped with the copper tape sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com