Composite material, moulding, electronic unit comprising moulding, and process for producing a moulding

A technology of composite materials and electronic devices, applied in measuring devices, chemical instruments and methods, measuring fluid pressure, etc., can solve problems such as unproven long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

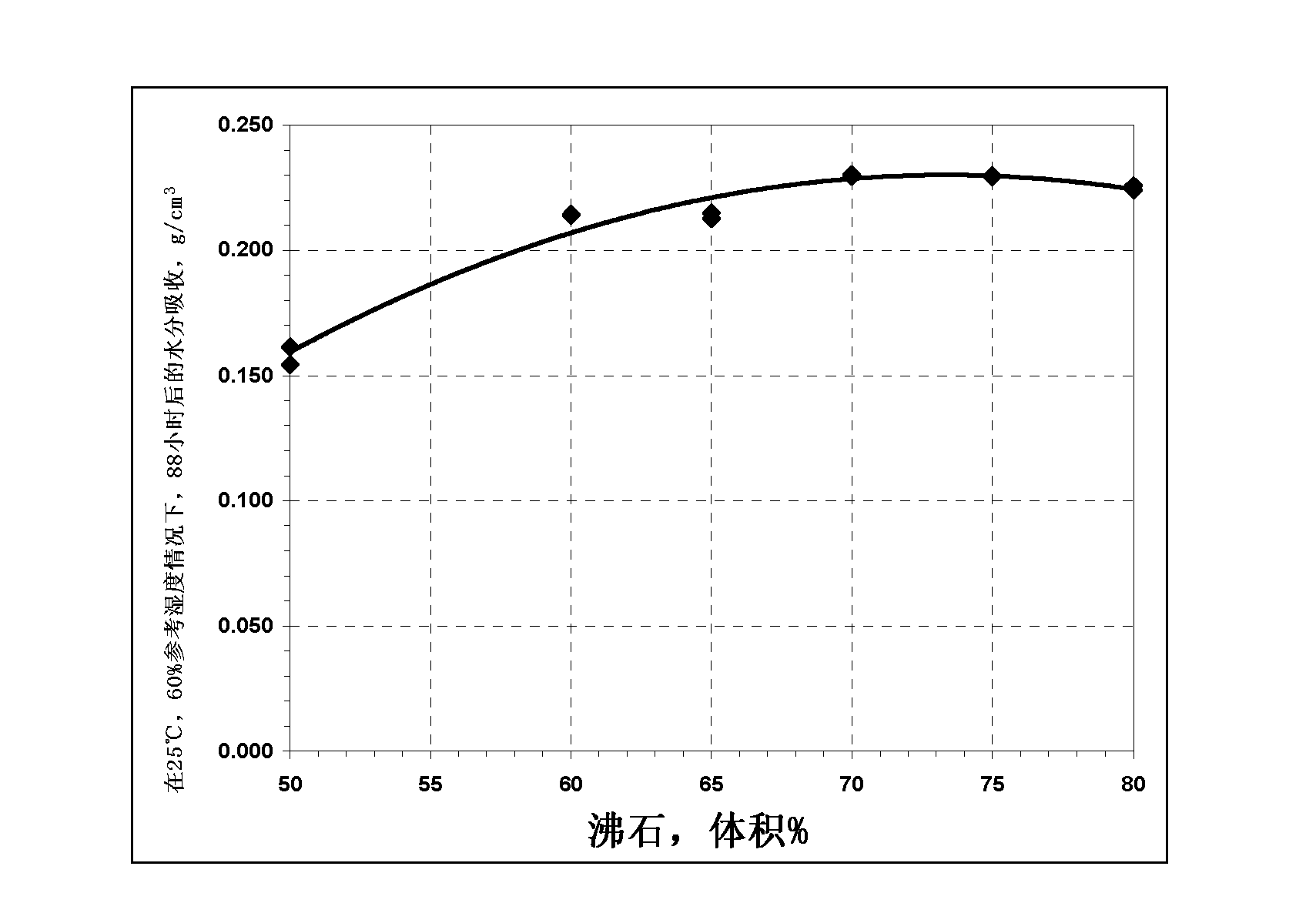

[0033] As the zeolite in this embodiment, the zeolites Purmol 4ST (Z4A) or 3ST (Z3A) from the company Zeochem are chosen. Both zeolites are white powders that react with water in a highly exothermic manner under dry conditions. The water absorption of the powder Z4A at 50% relative humidity and 20° C. within 24 hours was 24% by mass. For powder Z3A, under the same conditions, the maximum water absorption rate was 22% by mass.

[0034] For the polymer used in the polymer matrix in this embodiment, PFA was used, which was used as the aqueous dispersion DuPont Teflon PFA TE-7224. The dispersion is 60.4% by mass of PFA nanoparticles (50-500nm), about 5% by mass of nonionic surfactant and water. The viscosity is about 20 cP. The pH was 10, which is perfectly adequate for the pH of the zeolite in water (pH 10.3). The dispersion is completely dried at 100-120°C; at 250-290°C the surfactant is pyrolyzed; at 305-340°C the PFA particles melt and form 3D crosslinks in the composite. ...

PUM

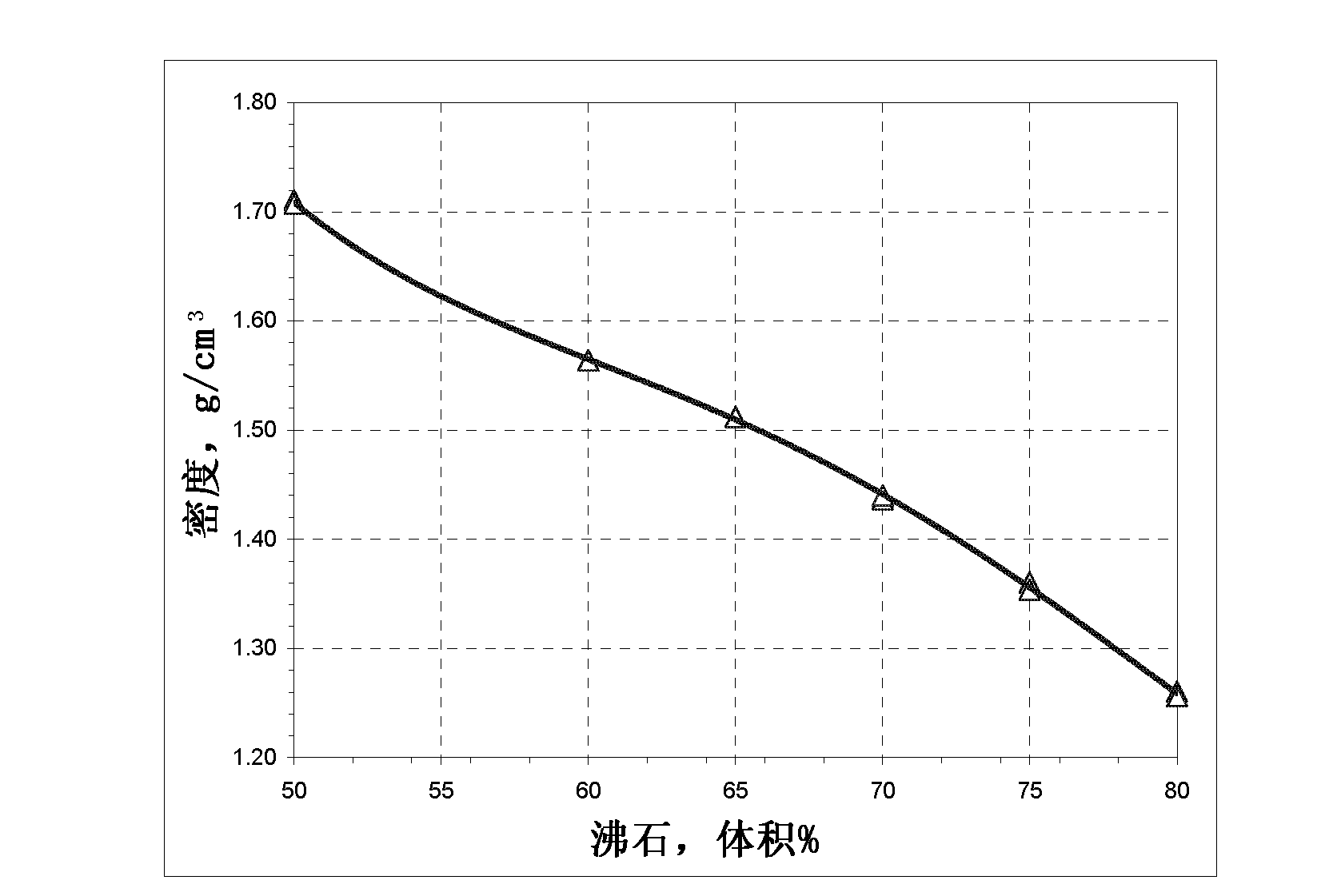

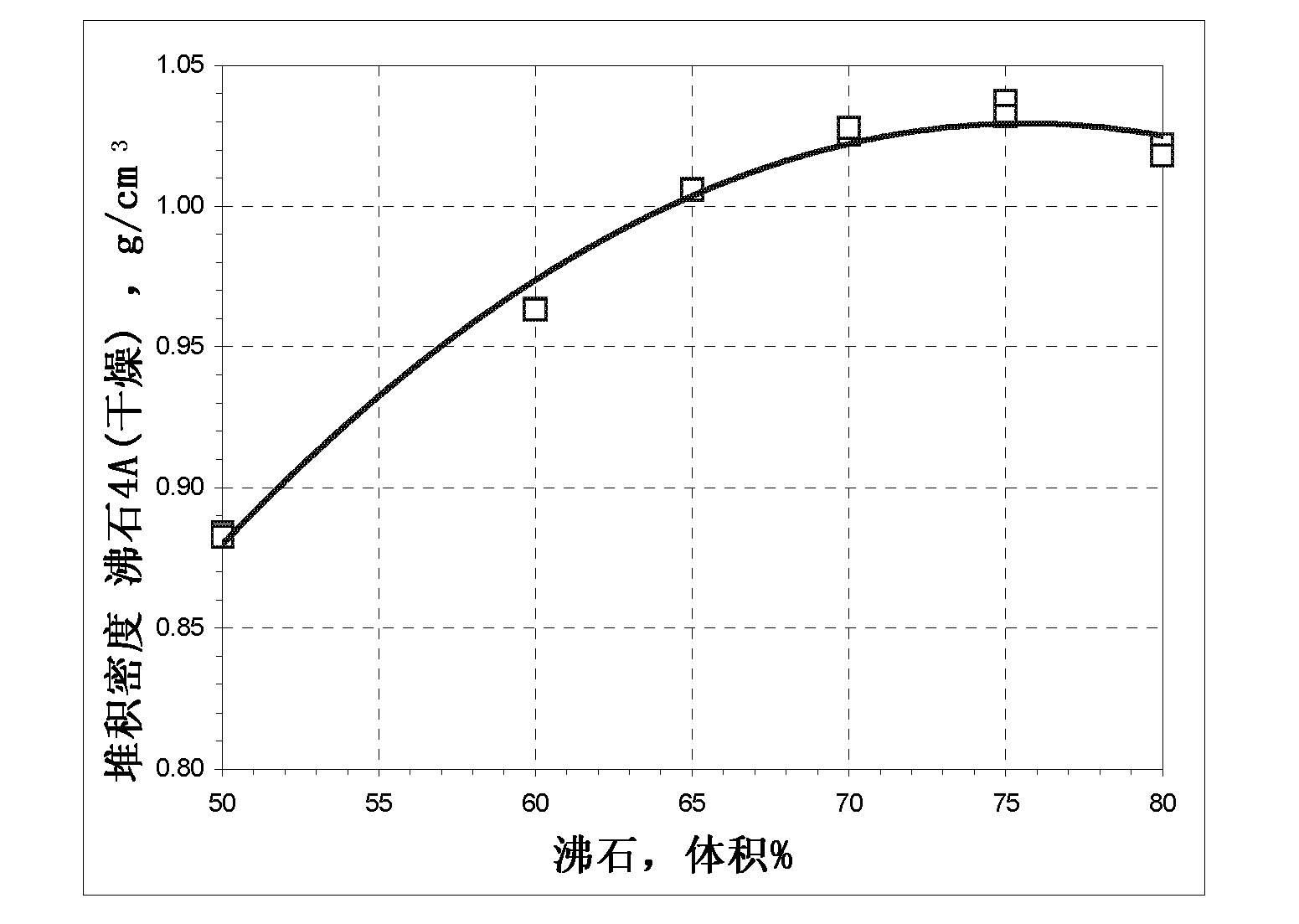

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com