Spring-loaded type fluorine lining safety valve and valve clack assembly thereof as well as processing method of valve clack assembly

A safety valve, spring-type technology, applied in the processing field of spring-type fluorine-lined safety valve and its valve disc assembly and valve disc assembly, can solve the problems of high price, easy leakage of bellows, and high cost, and achieves low price and high sealing performance. Good effect, ensure zero leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

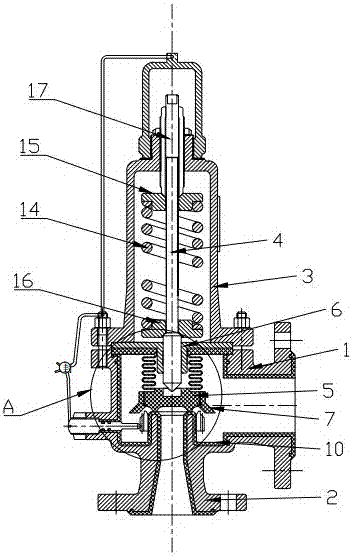

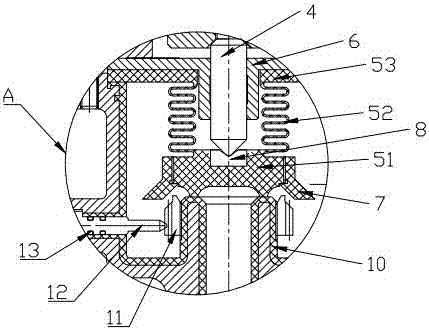

[0030] Such as Figure 1-3 As shown, a spring-type fluorine-lined safety valve includes a valve body 1, a valve seat 2, a valve cover 3, a valve stem 4, a valve disc assembly 5, a guide sleeve 6, and a recoil disc 7; the guide sleeve 6 is arranged on Between the valve body 1 and the valve cover 3, the valve stem 4 passes through the guide sleeve 6 to withstand the valve disc assembly 5, and an elastic assembly is arranged outside the valve stem 4 to drive the valve stem 4 downward;

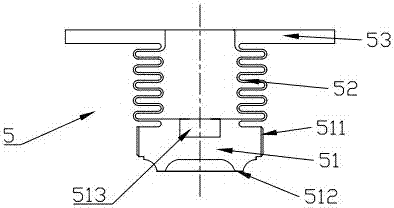

[0031] The surface of the inner cavity of the valve body 1 and the valve seat 2 is provided with a layer of fluorine-lined layer 10, and the valve body is provided with a dovetail groove to fix the fluorine-lined layer on the valve body to prevent falling off; the valve disc assembly 5 is made of fluoroplastic Integral processing and molding, including valve flap 51, bellows 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com