Front plate packaging structure of solar module

A solar module and packaging structure technology, applied in electrical components, semiconductor devices, photovoltaic modules, etc., can solve the problems of limited sunlight absorption effect, difficulty in obtaining transparency, and convenient installation, etc., and achieve excellent absorption effect and good optical matching characteristics , good light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

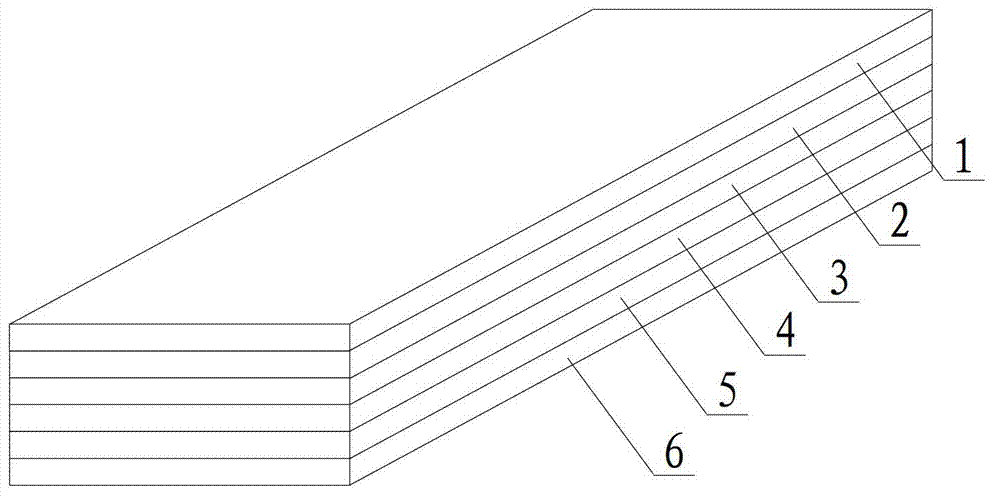

[0021] Such as figure 1 As shown, a front plate encapsulation structure of a solar module, on the upper surface of the solar cell module, an ETFE fluoroplastic film, a first EVA film, a battery sheet, a second EVA film and a back plate are sequentially arranged from bottom to top. The ETFE fluoroplastic film is composed of three superimposed semiconductor contacts. The bottom unit absorbs red light, the middle layer absorbs green light, and the upper layer absorbs blue light. It has high light penetration and the ability of the light sheet to absorb multiple spectra.

[0022] The light transmittance of the ETFE fluoroplastic film of the present invention is greater than 95%.

[0023] The weight of the ETFE fluoroplastic film of the present invention is 0.1kg / m 2 .

[0024] Compared with traditional tempered glass, the packaging structure of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com