Laminated refraction-reducing film for polycrystalline silicon solar cell

A solar cell and polysilicon technology, applied in circuits, electrical components, layered products, etc., can solve the problem that the anti-refractive film is difficult to obtain the anti-refractive effect, and achieve excellent anti-refractive effect, improve conversion efficiency, and good optical matching characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

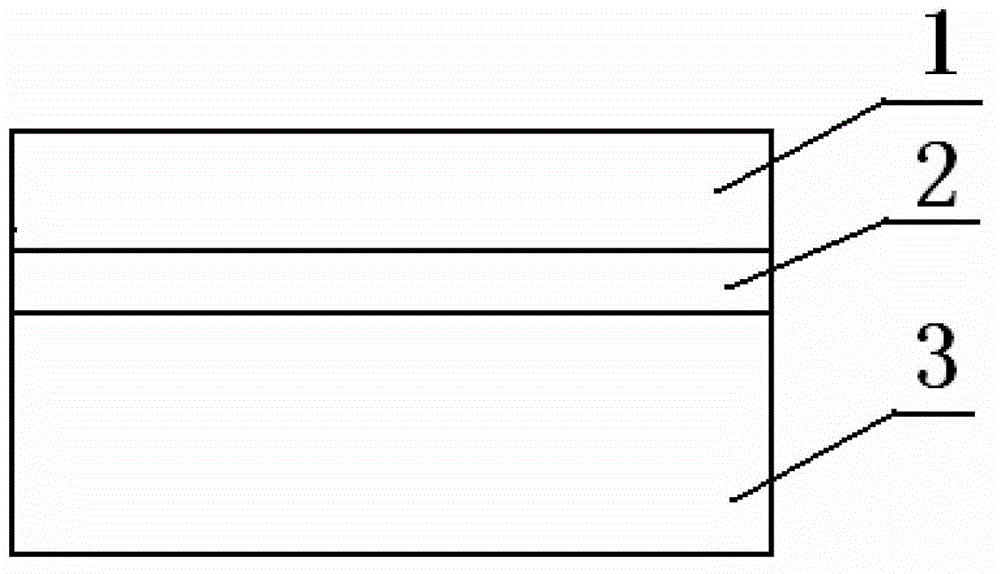

[0019] Such as figure 1 As shown, a laminated anti-refraction film for polysilicon solar cells, the laminated anti-refraction film is arranged on the front surface of the polysilicon substrate 3 of the solar cell, and consists of a silicon dioxide layer 2 and a silicon oxynitride layer 1 from the inside to the outside.

[0020] The silicon oxynitride layer 1 of the present invention has a thickness of 36-40 nm.

[0021] The silicon dioxide layer 2 of the present invention is a silicon dioxide hollow sphere film; the thickness of the silicon dioxide hollow sphere film is 18-20nm. The silicon dioxide hollow sphere film is used, the refractive index of which is 2.05, and the refractive index of the silicon oxynitride film is 1.5~1.8. Compared with the single layer film, this laminated film has better optical matching characteristics, not only for silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com