Process for preparing room temperature self-crosslinking acrylic ester emulsion modified by inorganic nano particle

A technology of inorganic nanoparticles and acrylates, which can be used in coatings and other directions to solve the problems of poor emulsion performance and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

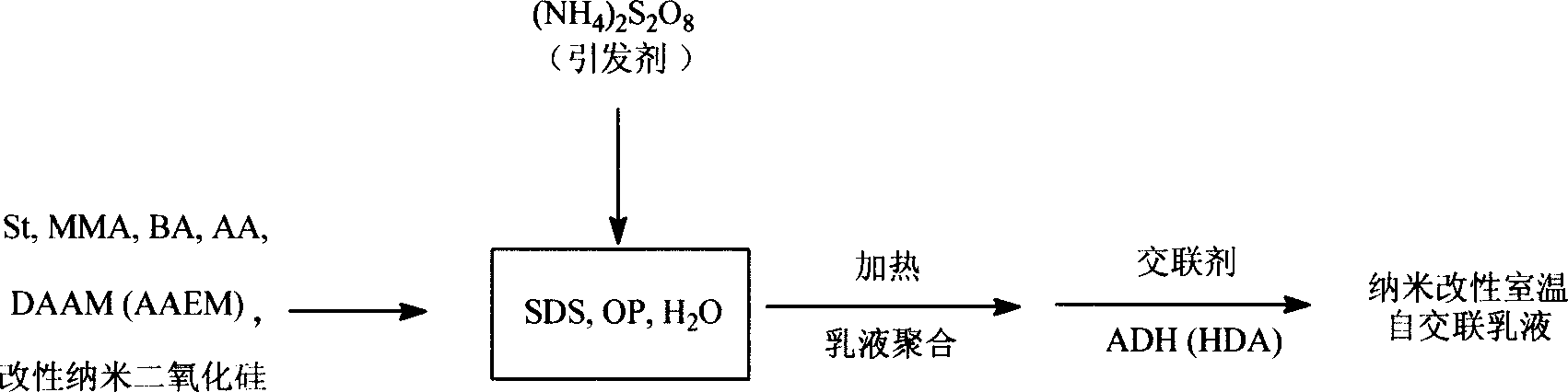

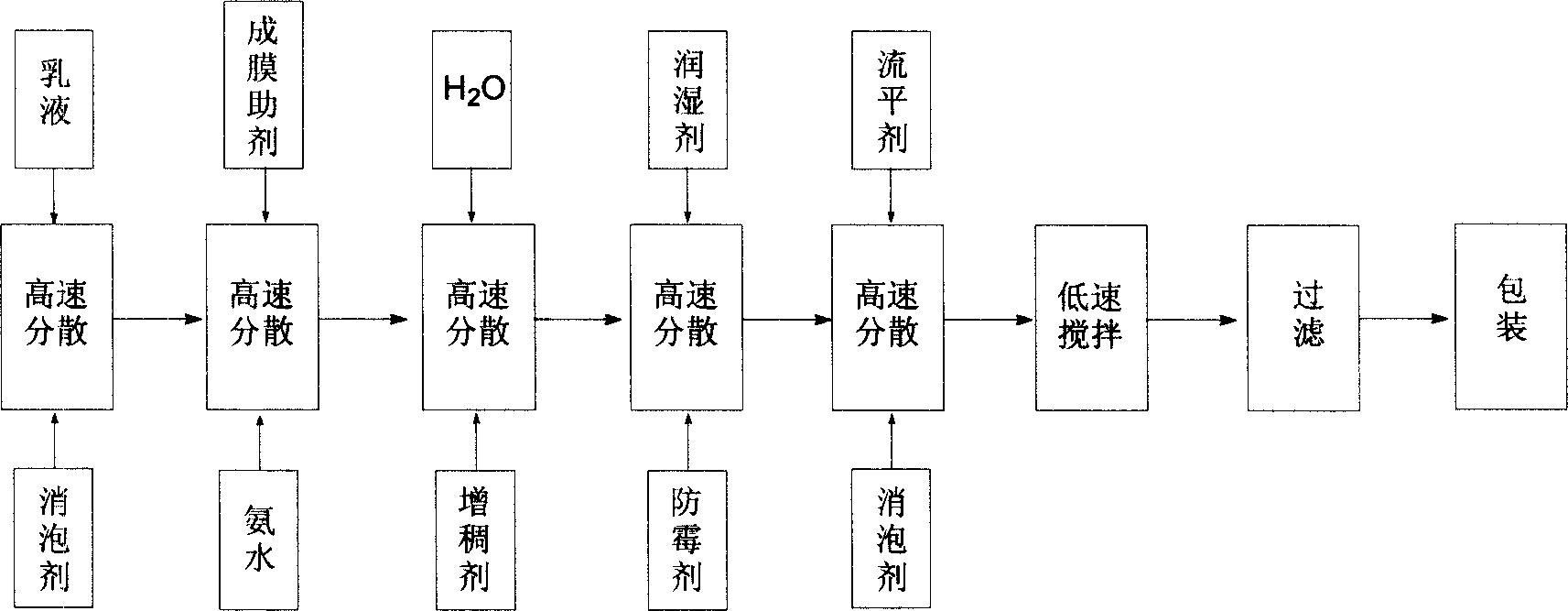

Method used

Image

Examples

Embodiment 1

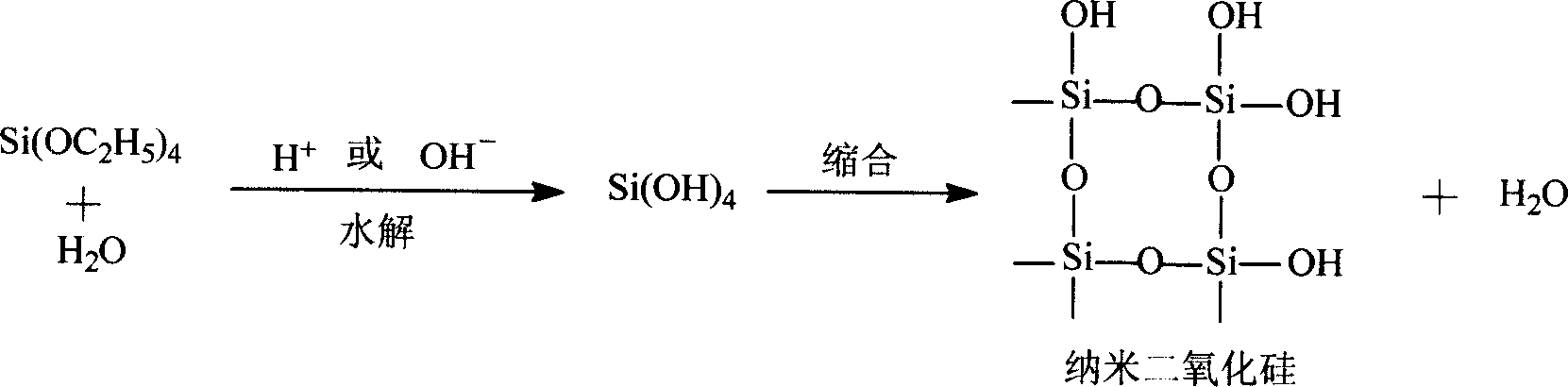

[0089] (1) Preparation method of surface modified nano-silica (1)

[0090] Add a mixed solution of ammonia water (4.1mL), ethanol (280mL) and water (32mL) into a 1000mL three-necked reactor equipped with a stirrer, a condenser and a dropping funnel, and add tetraethyl orthosilicate ( 100mL) and ethanol mixed solution (200mL). Under stirring at room temperature, slowly drop the mixed solution of tetraethyl orthosilicate and ethanol in the dropping funnel into the reaction kettle, after 12 hours, continue to stir for 12 hours to obtain nano-silica dispersion with blue light. liquid (nano silica particle size is about 80nm).

[0091] A mixed solution of methacryloxypropyltrimethoxysiloxane (MPS) (10 mL) and ethanol (50 mL) was slowly added dropwise to the above-mentioned nano-silica dispersion (MPS / nano-2 Silicon oxide=1:10 (molar ratio)), and then continue to stir for 12 hours, and distill most of the ethanol under reduced pressure to obtain nano-silica with unsaturated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com