Electroluminescence wire

一种场致发光线、发光层的技术,应用在电致发光光源、发光材料、光源等方向,能够解决成本高、有机染料分解褪色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

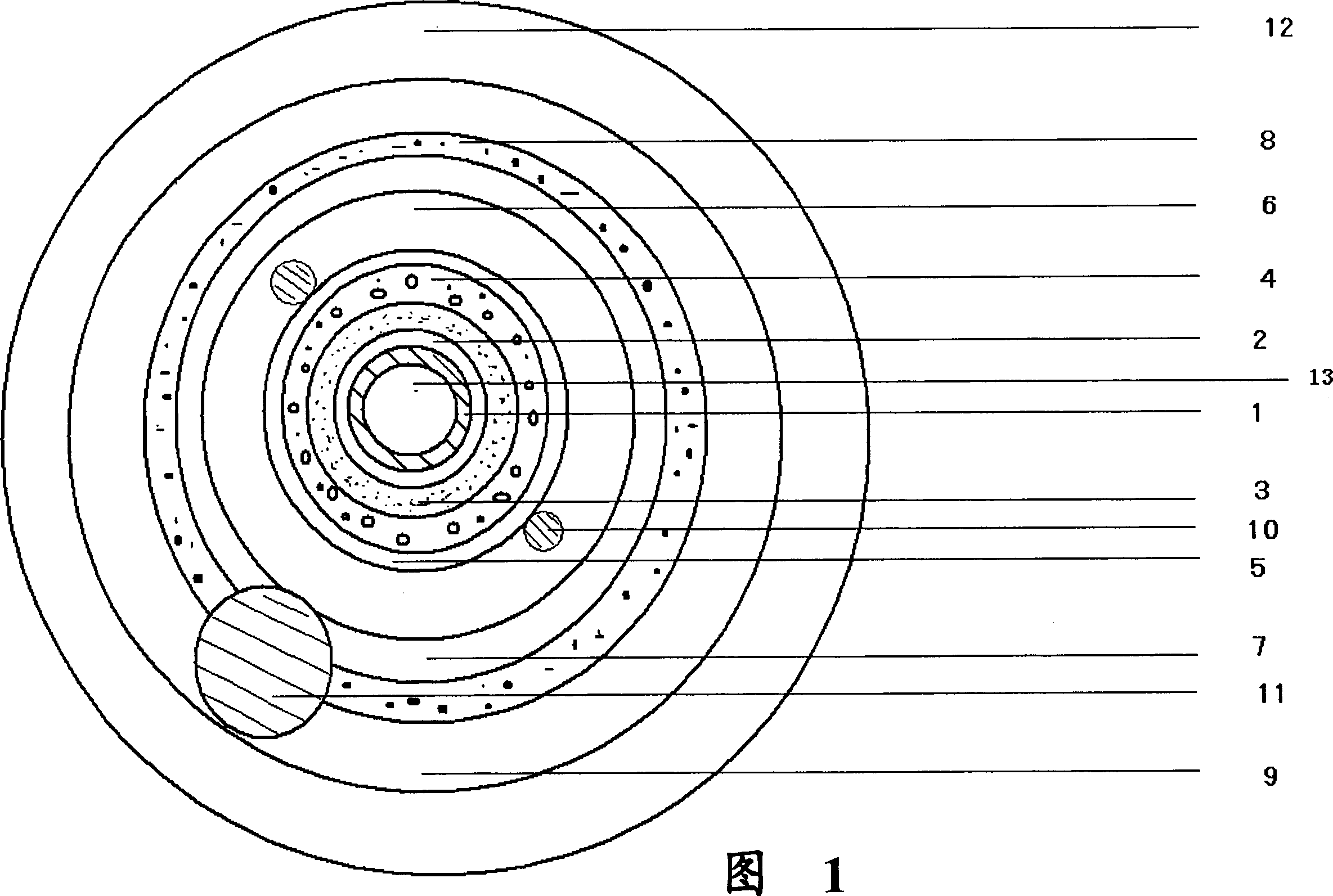

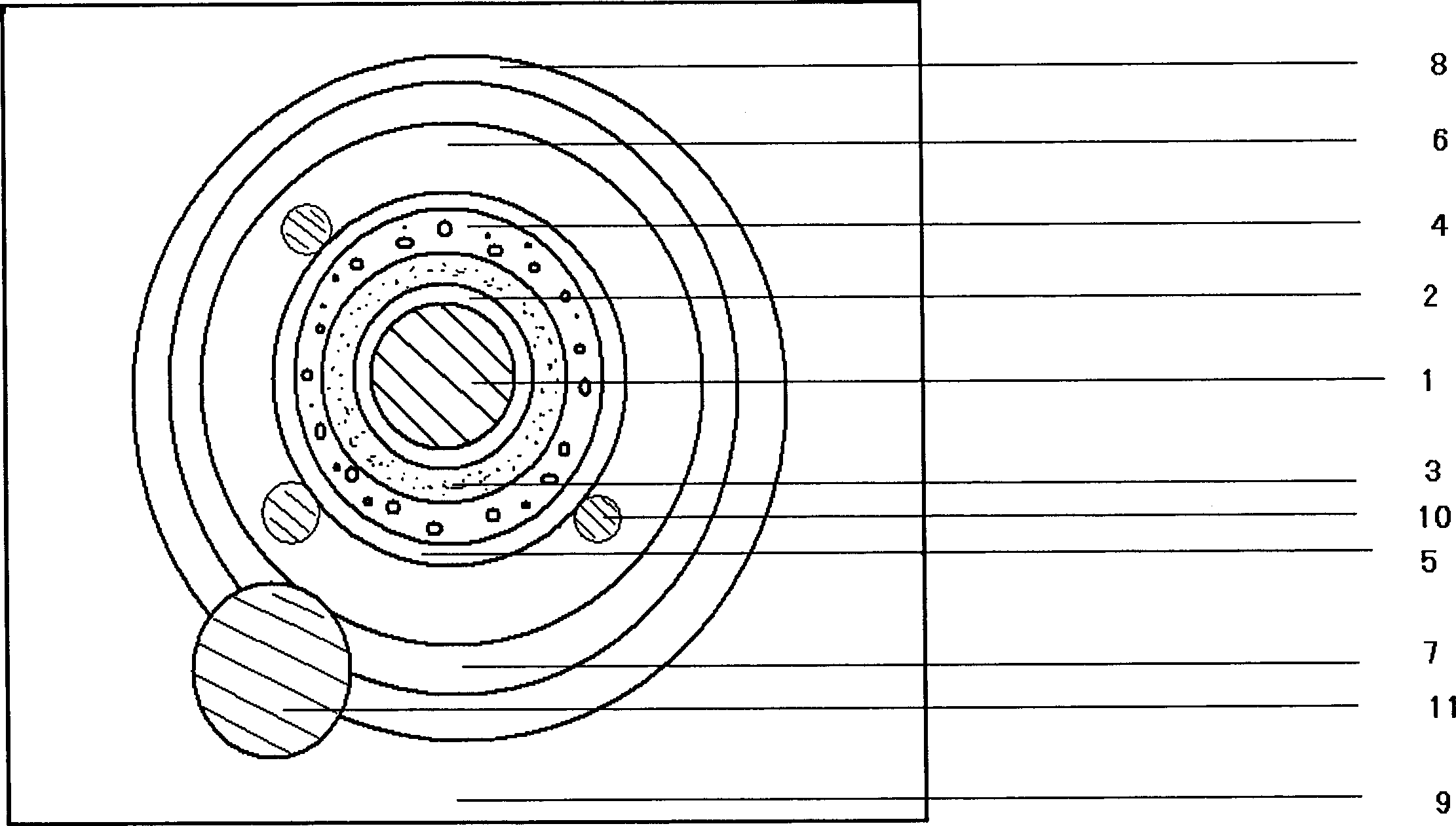

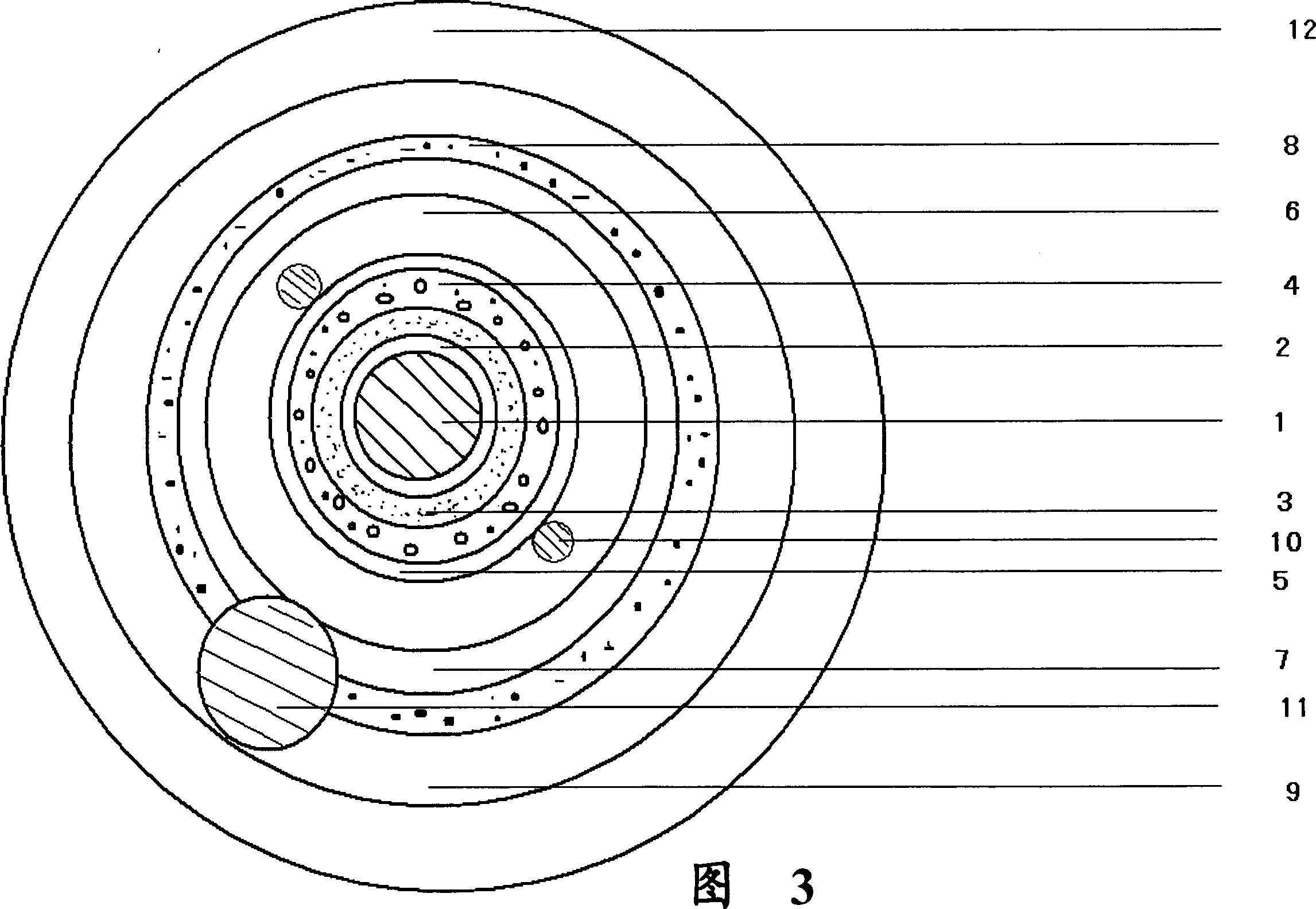

[0048]A continuous baseline body 1 is made of copper wire with a diameter of 0.5 mm. Its surface is coated with a finishing layer 2 of metal Sn. The metal modification layer is coated with a medium layer 3, which is formed by mixing medium slurry and medium powder and applying it uniformly and continuously by wire drawing coating method. The material used for the medium powder is barium titanate, and the main component of the medium slurry is Is: epoxy resin, cyanoethyl sugar, cyanoethyl cellulose, dimethyl formamide diluent, and adding 5% titanium coupling agent (based on the weight of luminescent powder), the weight ratio of medium powder to medium slurry The ratio is 1:1. After coating, the dielectric layer is cured at a temperature lower than 110°C, and the thickness does not exceed 0.2 mm. The luminescent layer 4 is coated with the electroluminescent powder and the luminescent layer slurry by using the brushed coating method. The electroluminescent powder is blue-green Z...

Embodiment 2

[0051] A continuous baseline body 1, whose material is a hollow plastic pipe with a diameter of 1.0 mm. Its surface is plated with a metal Ag modification layer 2 . The metal modification layer is coated with a dielectric layer 3, which is formed by mixing the dielectric slurry and the dielectric powder and applying it uniformly and continuously by wire drawing coating method. The material used for the dielectric powder is a mixture of titanium dioxide and lead titanate, the ratio 1:1, the main components of medium pulp are: epoxy resin, cyanoethyl sugar, cyanoethyl cellulose. Add 7% of silicon-containing coupling agent (based on the weight of luminescent powder), and the weight ratio of medium powder to medium slurry is 1:1. After coating, the medium layer is cured at a temperature lower than 110°C, and the thickness does not exceed 1 mm. . The light-emitting layer 4 is made of blue-green ZnS:Cu electroluminescence powder mixed with 20% YAG light-emitting material, and mixe...

Embodiment 3

[0054] A continuous baseline body 1 is made of copper wire with a diameter of 0.3 mm. Its surface is coated with a metal Sn decoration layer 2 . The metal modification layer is coated with a dielectric layer 3, and the dielectric layer is uniformly and continuously coated by a wire drawing coating method after mixing a dielectric slurry and a dielectric powder. The materials used for the dielectric powder are barium titanate and strontium titanate. Its ratio is 2:1, and the main components of the medium slurry are: epoxy resin, cyanoethyl sugar, cyanoethyl cellulose, dimethylformamide diluent, adding 10% of silane coupling agent (by weight of luminescent powder) . The weight ratio of the medium powder to the medium slurry is 1:1, and the medium layer is solidified at a temperature lower than 110°C after coating, and the thickness does not exceed 1 mm. The luminescent layer 4 is coated with the electroluminescent powder and the luminescent layer slurry by using the drawing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com