Cerium zirconium aluminum based multiple oxide material and preparing method thereof

A composite oxide, cerium zirconium aluminum technology, applied in chemical instruments and methods, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor anti-aging performance and improve anti-aging performance. , good oxygen storage performance, the effect of improving the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

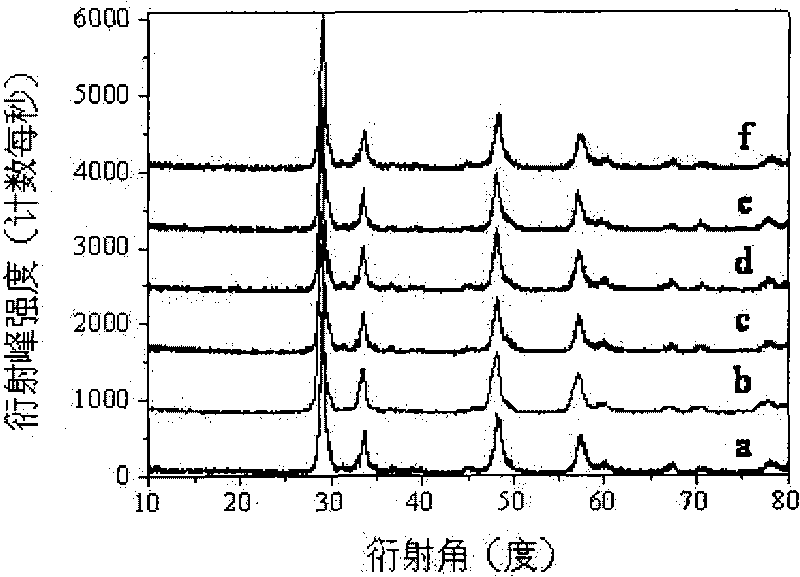

[0027] According to the preparation method provided by the present invention, the sintering conditions include a temperature of 450-800°C, preferably 450-600°C, and a sintering time of 1-10 hours, preferably 3-5 hours.

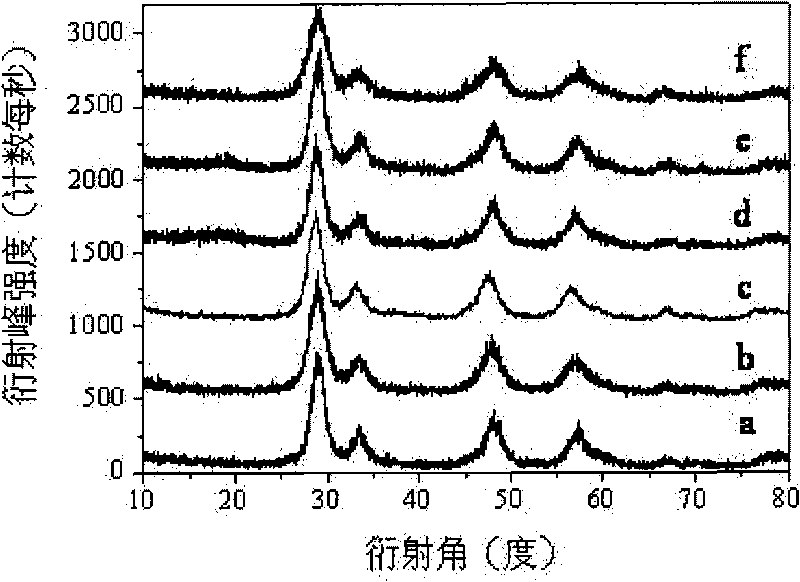

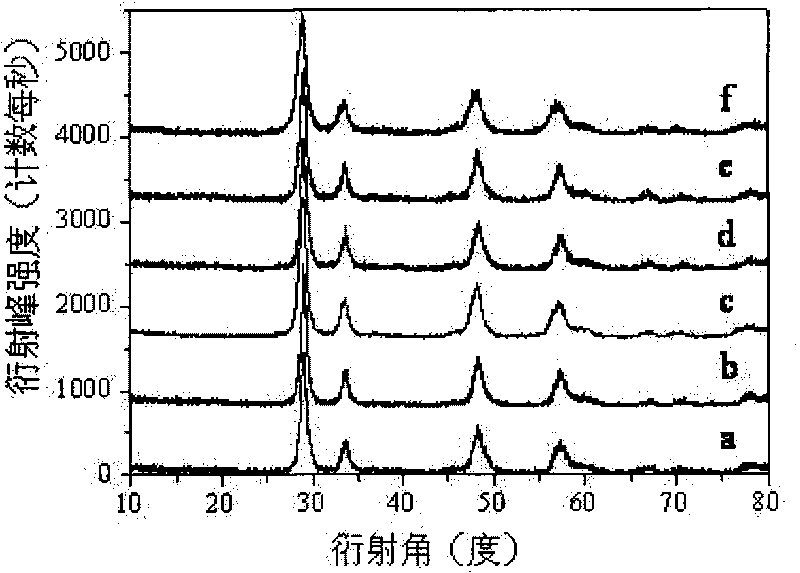

[0028] The morphology of composite oxide materials prepared by conventional co-precipitation method is mostly massive or granular, while the morphology of cerium-zirconium-aluminum-based composite oxide materials prepared according to the method provided by the present invention is spherical or nearly spherical, so the obtained cerium-zirconium-aluminum The specific surface area of the fresh sample of aluminum matrix composite oxide material is obviously higher.

[0029] The cerium-zirconium-aluminum-based composite oxide material prepared by the invention can be used as an auxiliary agent or a carrier for a three-way catalyst for automobile tail gas purification.

Embodiment 1

[0032] This example is used to illustrate the cerium-zirconium-aluminum-based composite oxide material and its preparation method of the present invention.

[0033] According to the composition of Al in the cerium-zirconium-aluminum matrix composite oxide material in Table 1 2 o 3 , CeO 2 , ZrO 2 、La 2 o 3 , Y 2 o 3 content, calculate the Y 2 o 3 And the weight of the precursor pseudo-boehmite (aluminum oxide content 57% by weight, Shandong Aluminum Plant), cerium nitrate, zirconium nitrate, and lanthanum nitrate of each oxide. Add 65% by weight of concentrated nitric acid dropwise to the above calculated amount of Y 2 o 3 until completely dissolved to obtain a nitrate solution of yttrium. The nitrate solution of yttrium obtained above and the calculated amount of pseudoboehmite, cerium nitrate, zirconium nitrate, and lanthanum nitrate were added to a 1000 ml three-necked flask, and dissolved in distilled water to form a total concentration of metal ions of 0.2mol / L...

Embodiment 2

[0038] This example is used to illustrate the cerium-zirconium-aluminum-based composite oxide material and its preparation method of the present invention.

[0039] According to the composition of Al in the cerium-zirconium-aluminum matrix composite oxide material in Table 1 2 o 3 , CeO 2 , ZrO 2 、La 2 o 3 and Eu 2 o 3 content, calculated Eu 2 o 3 And the weight of the precursor pseudo-boehmite (aluminum oxide content 57% by weight, Shandong Aluminum Plant), cerium nitrate, zirconium nitrate, and lanthanum nitrate of each oxide. Add 65% by weight of concentrated nitric acid dropwise to the above calculated amount of Eu 2 o 3 until completely dissolved to obtain a nitrate solution of europium. Add the nitrate solution of europium obtained above and the calculated amount of pseudo-boehmite, cerium nitrate, zirconium nitrate, and lanthanum nitrate into a 1000 ml three-necked flask, and dissolve with distilled water to make a total concentration of metal ions of 0.2mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com