SBS (styrene-butadiene-styrene)/scrap rubber powder composite modified asphalt and preparation method thereof

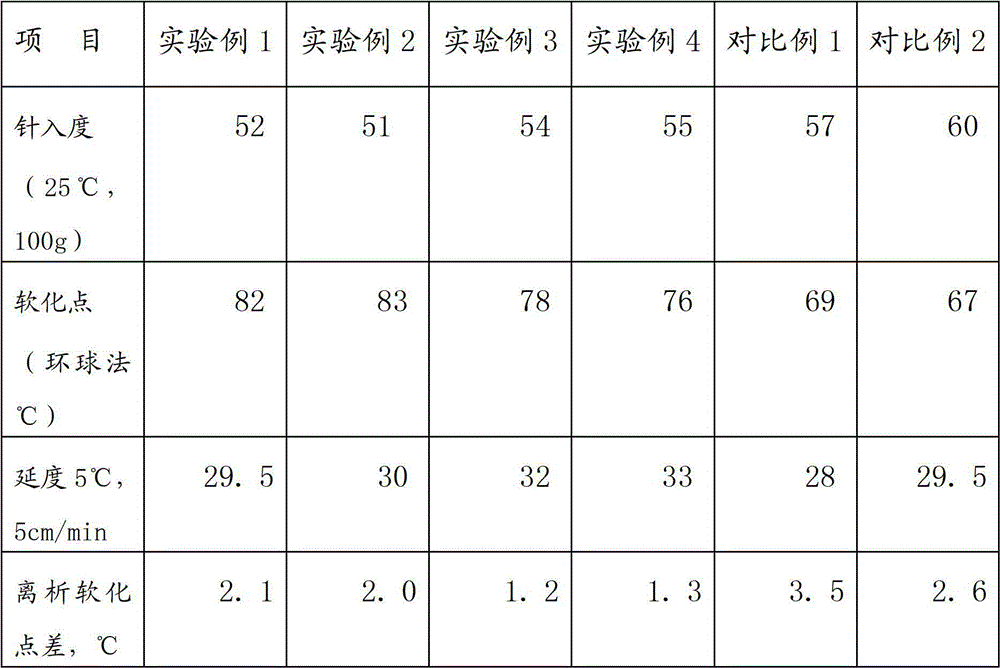

A technology of composite modified asphalt and waste rubber powder, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of vulcanized rubber network structure damage, high-temperature performance degradation of modified asphalt, and increased cost of modified asphalt materials. Achieve the effect of prolonging the stable period of high temperature storage, strengthening the anti-aging performance and reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

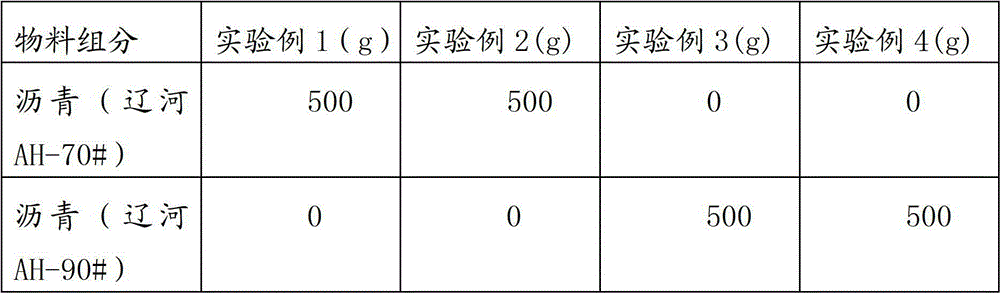

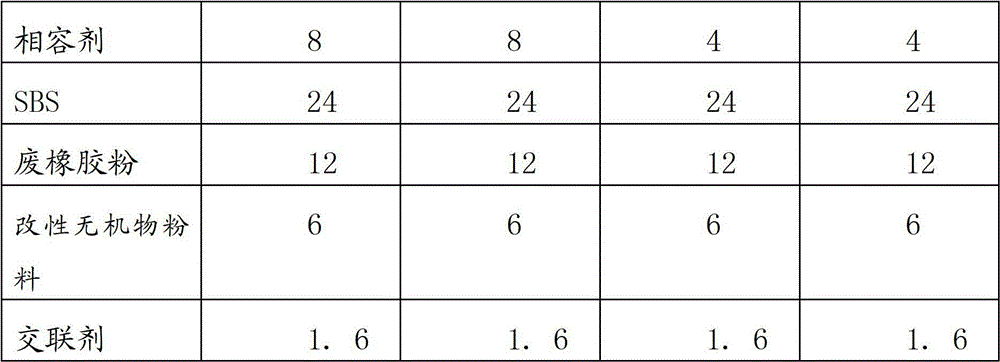

[0021] A composite modified asphalt of SBS and waste rubber powder, comprising the following components, by weight (g), base asphalt 75g waste rubber powder 0.5g styrene-butadiene-styrene triblock copolymer (SBS) 3.2g clay and calcium carbonate 0.2g furfural extract oil 0.1g sulfur powder and sulfur donor 0.1g.

[0022] The preparation method of above-mentioned SBS, waste rubber powder composite modified asphalt is as follows:

[0023] 1) Preparation of waste rubber powder: waste rubber powder is prepared by normal temperature crushing method, normal temperature additive method, low temperature freezing method or wet crushing method, and the particle size of waste rubber powder is 30-220 mesh;

[0024] 2) Heat the base asphalt to 160-180°C until it reaches a completely fluid state, and add compatibilizer under stirring until it is evenly mixed;

[0025] 3) Continue heat preservation and stirring, add SBS, waste rubber powder, clay and calcium carbonate mixture, heat preservat...

Embodiment 2

[0028] A composite modified asphalt of SBS and waste rubber powder, comprising the following components, by weight (g),

[0029] Base bitumen 96g Waste rubber powder 2g Styrene-butadiene-styrene triblock copolymer (SBS) 6g Wollastonite powder 2g Oil-based plasticizer 6g Dicumyl peroxide 3g.

[0030] The preparation method of the above-mentioned SBS and waste rubber powder composite modified asphalt is as in Example 1 with specific steps.

Embodiment 3

[0032] A composite modified asphalt of SBS and waste rubber powder, comprising the following components, by weight (g),

[0033] Base bitumen 85g Waste rubber powder 2g Styrene-butadiene-styrene triblock copolymer (SBS) 5g Gypsum powder 5g Aromatic hydrocarbon oil 8g Maleimide 0.1g.

[0034] The preparation method of the above-mentioned SBS and waste rubber powder composite modified asphalt is as in Example 1 with specific steps.

[0035] The base asphalt is one or more of petroleum asphalt, natural asphalt or coal tar pitch.

[0036] The average molecular weight of the styrene-butadiene-styrene triblock copolymer is 30,000-460,000.

[0037] The modified inorganic powder is one or more of pottery clay, calcium carbonate, wollastonite powder, silica micropowder or gypsum powder.

[0038] The compatibilizer is one or more of furfural extracted oil, petroleum plasticizer, vacuum distillate oil or aromatic hydrocarbon oil.

[0039] The crosslinking agent is sulfur powder, sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com