Bituminous composition with thermoreversible properties

a technology of composition and bitumen, applied in the field of bitumens, can solve the problems of blown bitumen being more susceptible to ageing than the original bitumen, not always sufficiently efficient in the technique, and not always completely free of light fractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of a Bitumen / Organogelator Composition of Formula (I)

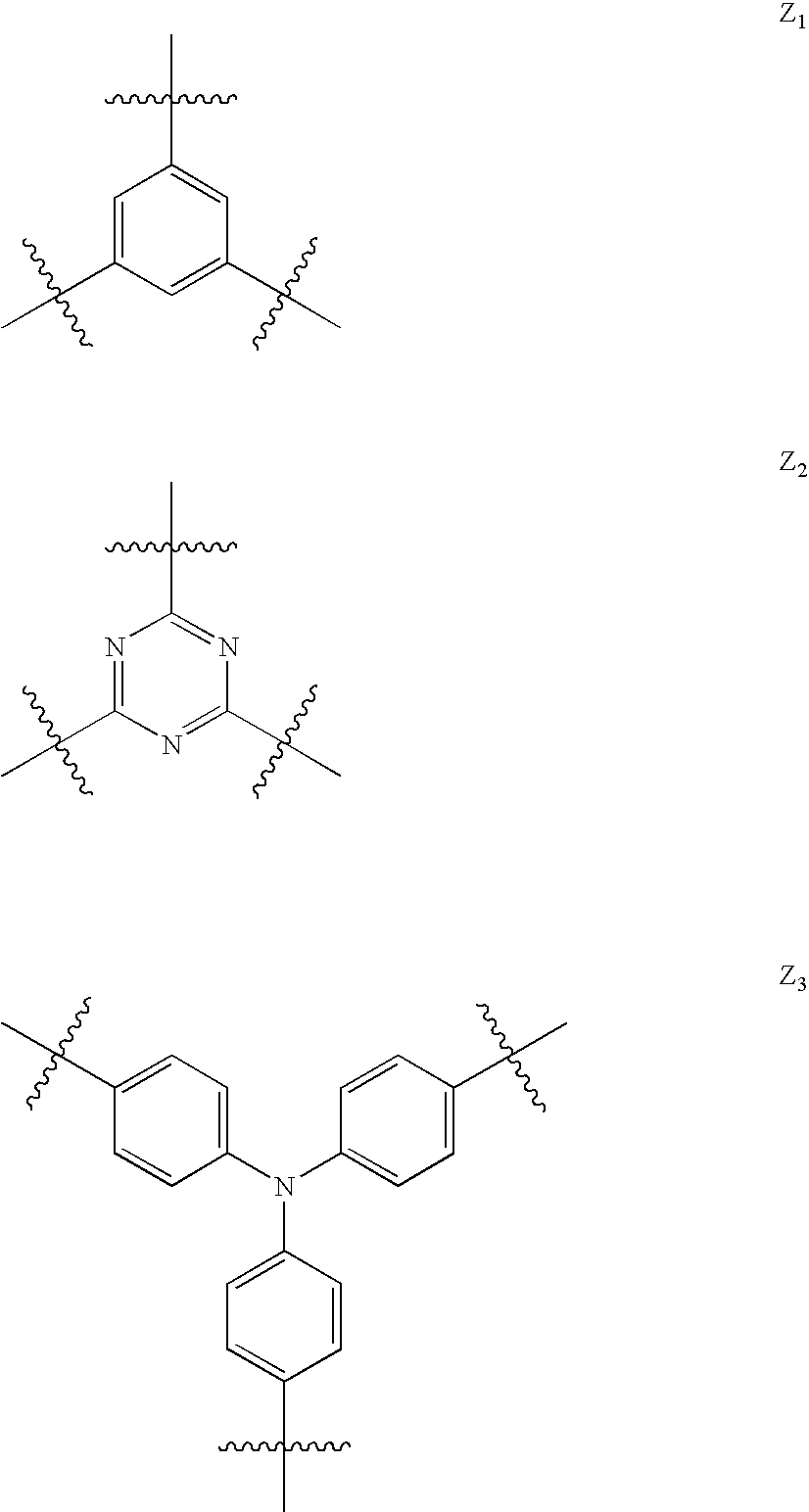

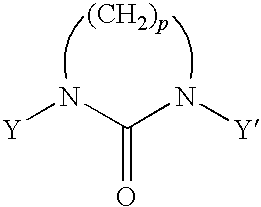

[0095]This first example relates to bitumen+organogelator compositions of general formula (I) according to the invention. Five types of organogelling molecules have been used in this example, at different concentrations. Their chemical structures are as follows:

C5H11—CONH—NHCO—C5H11 (1)

C9H19—CONH—NHCO—C9H19 (2)

C11H23—CONH—NHCO—C11H23 (3)

C17H35—CONH—CH2—CH2—NHCO—C17H35 (4)

C12H25—NHCONH—C6H4—CH2—C6H4—NHCONH—C12H25 (5)

[0096]The preparations are produced at 160-170° C., in a reactor with stirring. The control bitumen C1 is introduced into the reactor first. Then, the organogelator is added. The mixtures are stirred for approximately 60 minutes. Their final appearance is homogeneous. The mixtures are cooled down to ambient temperature. The control bitumen C1 is a direct distillation bitumen of grade 70-100 the characteristics of which correspond to the standard NF EN 12591.

TABLE 2Nature of theOrganogelatorCompositionso...

example 2

Preparation of a Bitumen / Organogelator Composition with Organogelling Molecules of a Different Nature (VII)

[0113]The compositions are prepared in the same way as in example 1. The organogelator concentration is 3%. The organogelator (for example C13 or C14) is constituted by a first type T1 of organogelling molecules (A1) and by a second type T2 of organogelling molecules (B1 or B2). The molar ratio of the two types T1 and T2 is 1 to 1.

[0114]Aminopyrimidine+barbituric acid

[0115]The composition C13 comprises an aminopyrimidine derivative A1, 5-octyl-2,4,6-triaminopyrimidine and a barbituric acid derivative B1, 5,5-dioctylbarbituric acid. The C14 composition comprises an aminopyrimidine derivative A1, 5-octyl-2,4,6-triaminopyrimidine and barbituric acid B2.

TABLE 4Ringand ballsofteningCom-PenetrabilitypointPfeifferViscosityViscositypositionsP25(RBSP)index PIat 140° C.at 160° C.C17647.5−0.8267165C135952.0−0.31276168C146152.5−0.11311186

[0116]Phenol+sulphosuccinate

[0117]The C15 compositio...

example 3

Preparation of a Bitumen / Organogelator Composition with a Sorbitol Derivative (III) 1,3:2,4-Di-O-benzylidene-D-sorbitol (DBS) As Organogelator

[0118]The compositions are prepared in the same way as in example 1. The organogelator is used at different concentrations.

TABLE 6OrganogelatorCompositionsconcentrationC1 (control)0%C193%C201%C210.66% C220.33% C230.1%

[0119]The results obtained are recorded in Table 7 below:

TABLE 7Ringand ballsofteningCom-PenetrabilitypointPfeifferViscosityViscositypositionsP25(RBSP)index PIat 140° C.at 160° C.C1 (control)7646.6−1.0267165C193616110310125C2039143.59.31314118C2146131.58.95298115C2255946.28257113C237447.8−0.82253111

[0120]It is noted that the addition of DBS makes it possible to significantly increase the ring and ball temperature of the compositions even at low DBS concentrations (see for example C22). The penetrability also reduces with the addition of DBS. The viscosities at 140° C. and 160° C. of the compositions with additives are equivale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com