Fluorine rubber composition and bladder for tire production

一种氟橡胶、组合物的技术,应用在胎、应用、中空物品等方向,达到有利机械特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

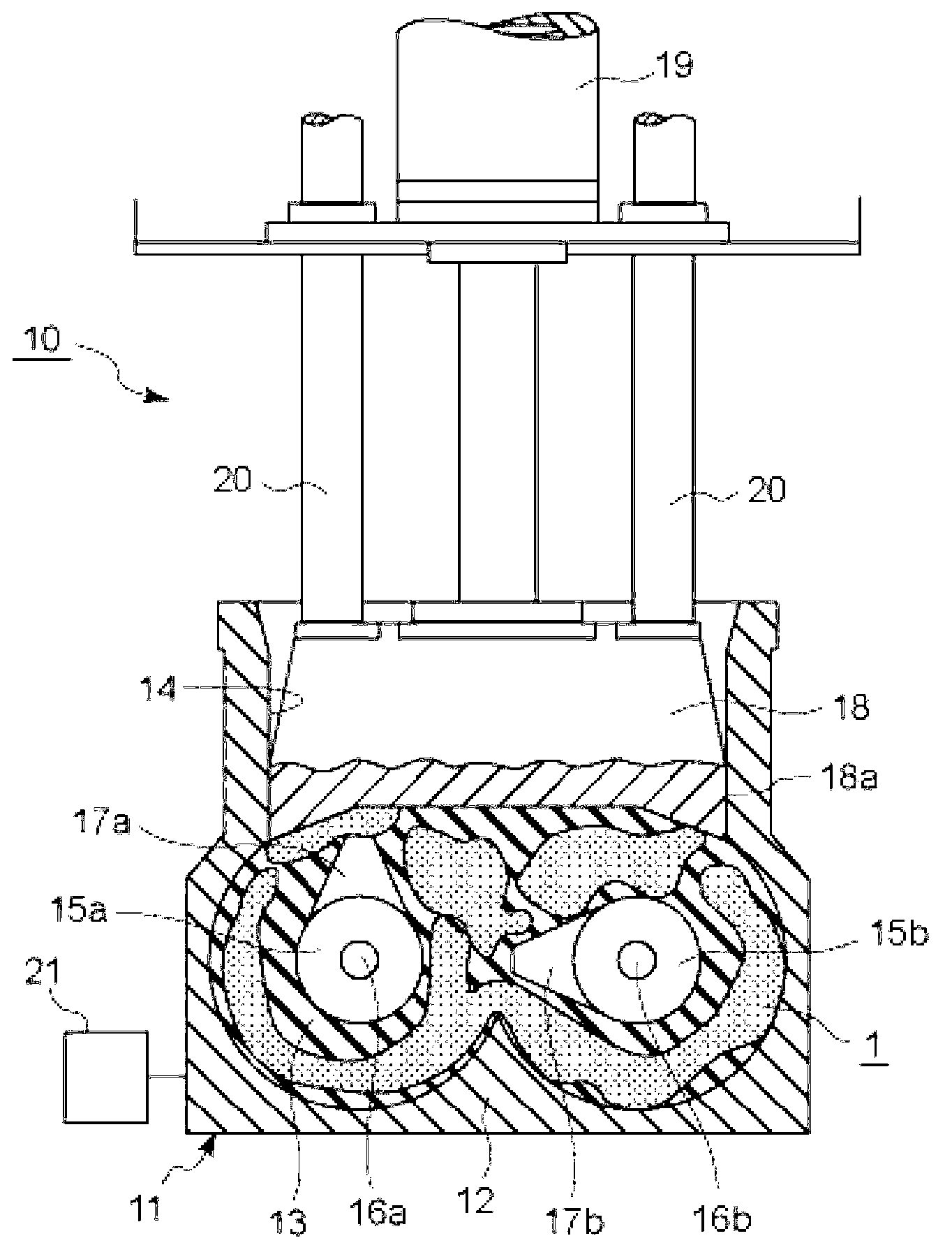

Image

Examples

Embodiment

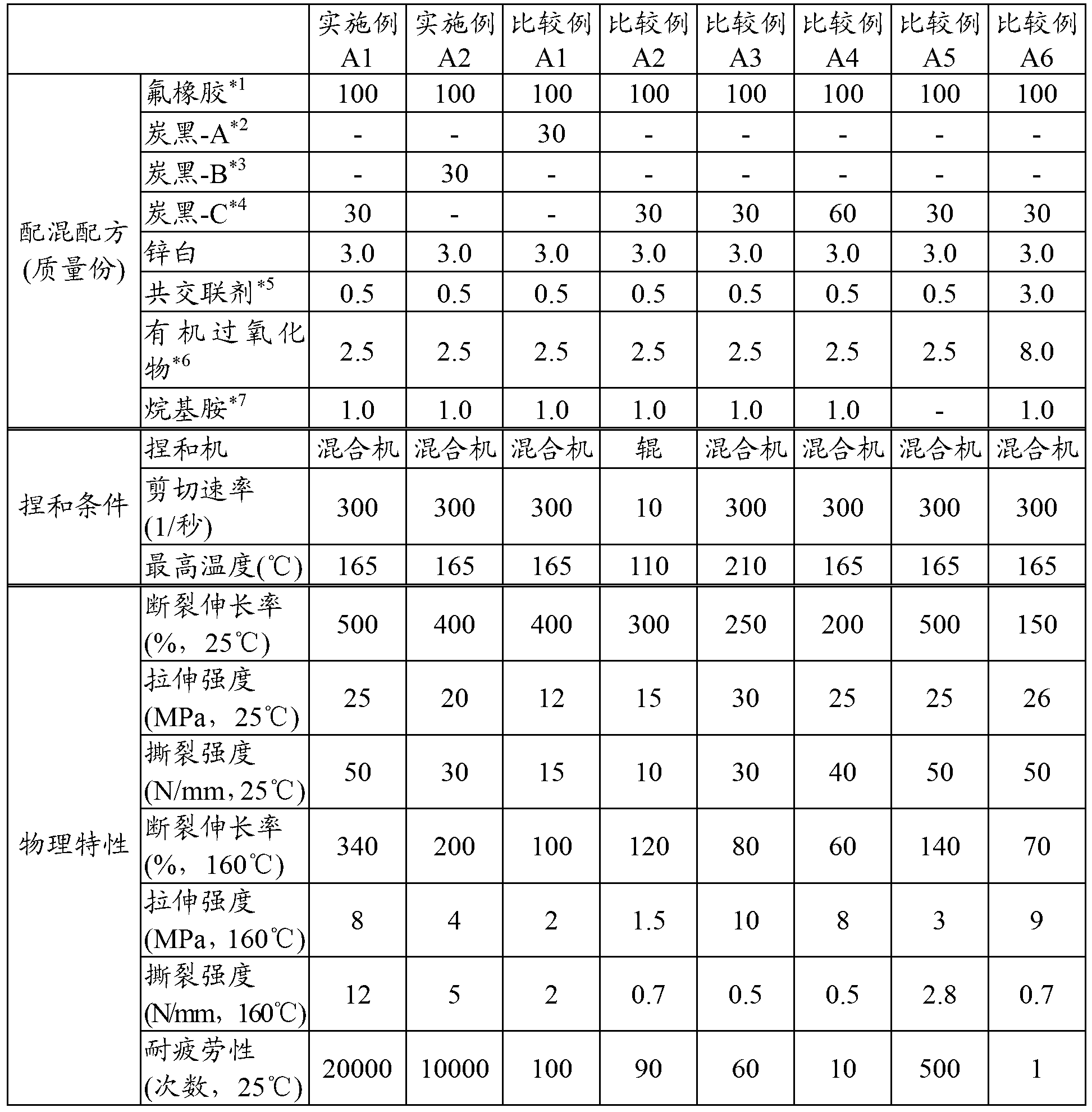

[0095] Hereinafter, the present invention will be described in more detail with reference to the following examples, but it should be understood that the present invention is not limited thereto at all.

[0096] The characteristics were measured according to the following methods.

[0097] (1) Elongation at break (%) and tensile strength (MPa):

[0098] Measurement was performed at 25°C and 160°C according to JIS K6251:2004. Regarding the samples, a dumbbell-shaped No. 3 shape was used with respect to the results shown in Table 1, and a dumbbell-shaped No. 6 shape was used with respect to the results shown in Table 2 (thickness of the parallel portion of each dumbbell: 2 mm) .

[0099] (2) Tear strength (N / mm):

[0100] Measurement was performed at 23°C and 160°C according to JIS K6252:2001. As for the sample, an unnotched angle shape (thickness: 2 mm) was used.

[0101] (3) Fatigue resistance:

[0102] A De Mattia flex-cracking test was performed according to JIS K6260:...

Embodiment A1-A2 and comparative example A1-A6

[0104] (Manufacture of fluororubber composition)

[0105] According to each compounding shown in Table 1, the kneading step (A) of kneading the components excluding the co-crosslinking agent and the organic peroxide with the fluororubber and carbon black was carried out under the conditions shown in the table, And when the kneading temperature reaches the maximum temperature T m , the kneaded material was discharged to obtain a masterbatch (mixture). In addition, as a kneader, an internal mixer with a kneading capacity of 1 liter (DS1-5MHB-E model kneader, manufactured by Moriyama Company Ltd.) was used; and as a type of roll, a 10-inch roll ( Manufactured by Sakurai Roll K.K.).

[0106] After undergoing an aging step in which the masterbatch obtained in the kneading step (A) was left at room temperature (23° C.) for 12 hours, the co-crosslinking agent and organic peroxide shown in Table 1 were added to the aforementioned masterbatch material, and the contents were kneaded ...

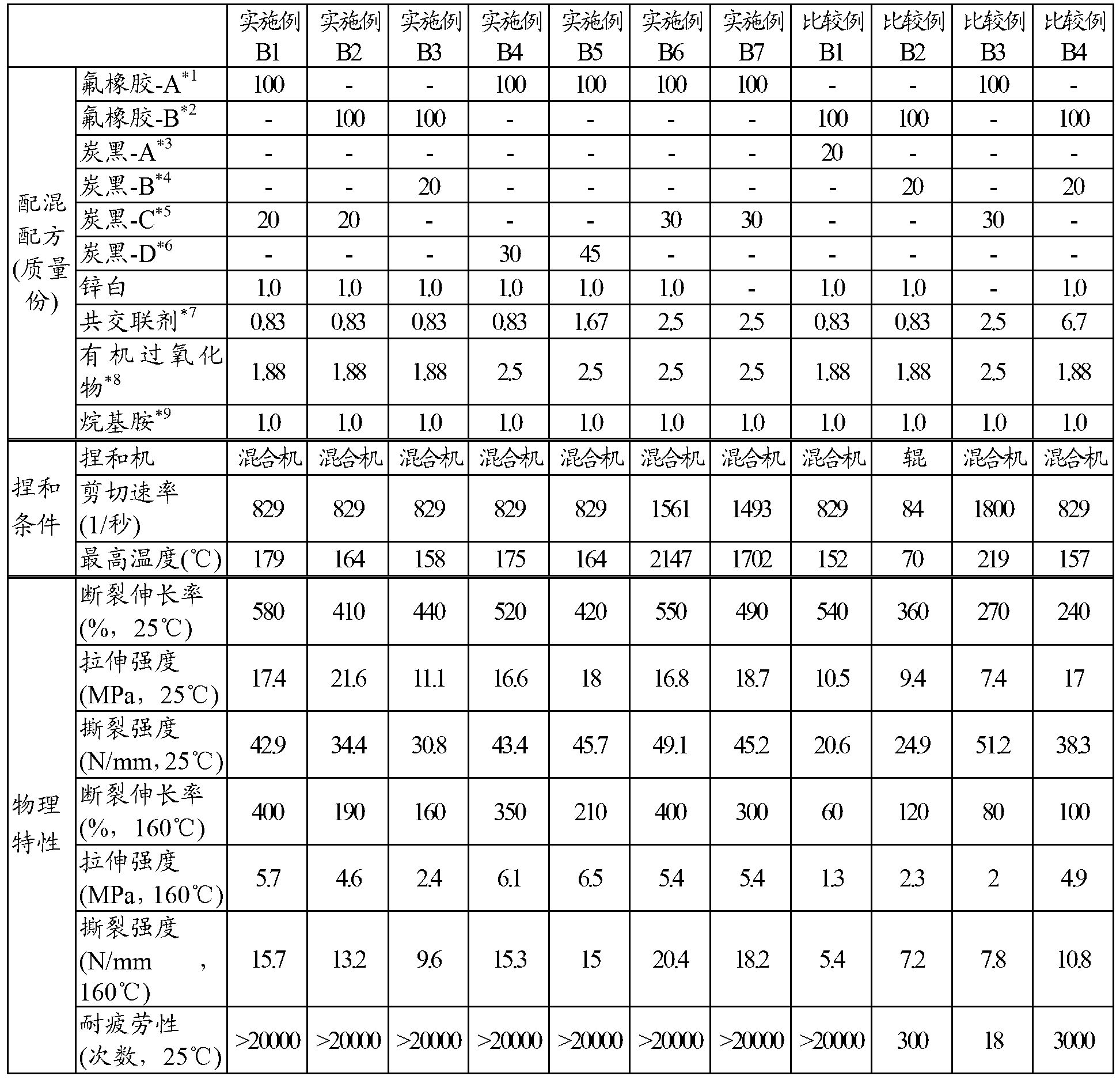

Embodiment B1-B7 and comparative example B1-B4

[0121] (Manufacture of fluororubber composition)

[0122] According to each compounding shown in Table 2, the kneading step (A) of kneading the components excluding the co-crosslinking agent and the organic peroxide with the fluororubber and carbon black was carried out under the conditions shown in the table, And when the kneading temperature reaches the maximum temperature T m , the kneaded material was discharged to obtain a masterbatch (mixture). In addition, a 0.5-liter internal type mixer (MIX-LABO, manufactured by Moriyama Company Ltd.) and a 35-liter internal type mixer (manufactured by Toshin Co., Ltd.) were used as the mixing type kneader, and using An 8-inch roll (manufactured by Kansai Roll Co., Ltd.) and a 22-inch roll (manufactured by Kobe Kikai K.K.) were used as the roll type.

[0123] After undergoing an aging step in which the masterbatch obtained in the kneading step (A) was left at room temperature (23° C.) for 12 hours, the co-crosslinking agent and orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com