Preparation method of radiation-heatable MXene/polymer composite material

A technology of polymer materials and composite materials, applied in the field of preparation of MXene/polymer composite materials, can solve the problem that polymer fabrics cannot have radiation heating, electric and light heating modes at the same time, and achieve mild conditions, simple and safe preparation methods, The effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of the MXene / polymer composite material that can be radiated heat, comprises the following steps:

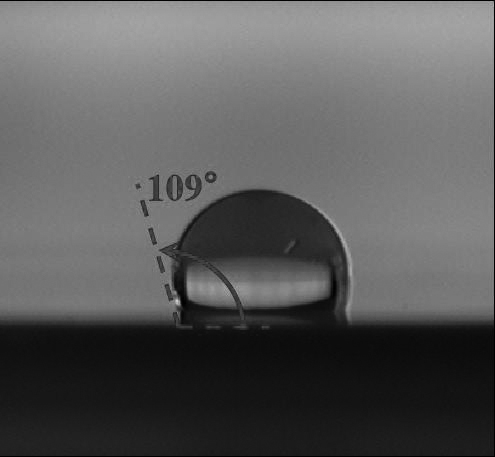

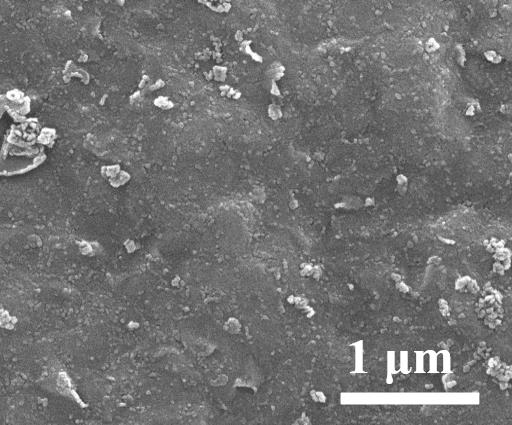

[0033] (1) Soak the nanoporous polyethylene film (nanoPE) in 2mg / mL dopamine hydrochloride solution at room temperature, wash the soaked nanoPE film with deionized water, and dry it at 25°C to prepare the pretreated nanoPE film;

[0034] (2) At room temperature, add 30g LiF into 300mL, 25mol / L HCl solution, stir for 30min to prepare etching solution; add 20g Ti 3 AlC 2 The phase powder was added to the etching solution, and stirred at 35°C for 24 hours to obtain the reaction product; the reaction product was diluted and poured into a centrifuge tube, centrifuged at 3500rpm for 5min, the supernatant was separated, and the centrifugation was repeated until pH ≥ 6. Ti 3 C 2 T x , in the precipitated Ti 3 C 2 T x After adding deionized water, shake it by hand for 7 minutes, centrifuge it at 3500rpm for 7 minutes, and get 4.3mg / mL Ti after u...

Embodiment 2

[0037] A kind of preparation method of the MXene / polymer composite material that can be radiated heat, comprises the following steps:

[0038] Referring to Example 1, an MXene / nanoPE composite film was prepared; the difference from Example 1 was that the concentration of the dopamine hydrochloride solution was 3.5 mg / mL; the concentration of the MXene solution was 5.2 mg / mL.

Embodiment 3

[0040] A kind of preparation method of the MXene / polymer composite material that can be radiated heat, comprises the following steps:

[0041] Referring to Example 1, an MXene / nanoPE composite film was prepared; the difference from Example 1 was that the concentration of the dopamine hydrochloride solution was 4.7 mg / mL; the concentration of the MXene solution was 6.1 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com