Vibration fatigue testing method for large-bypass-ratio engine fan blade with shoulder

A technology with large bypass ratio and vibration fatigue, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc., and can solve problems such as inability to assess near shoulders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

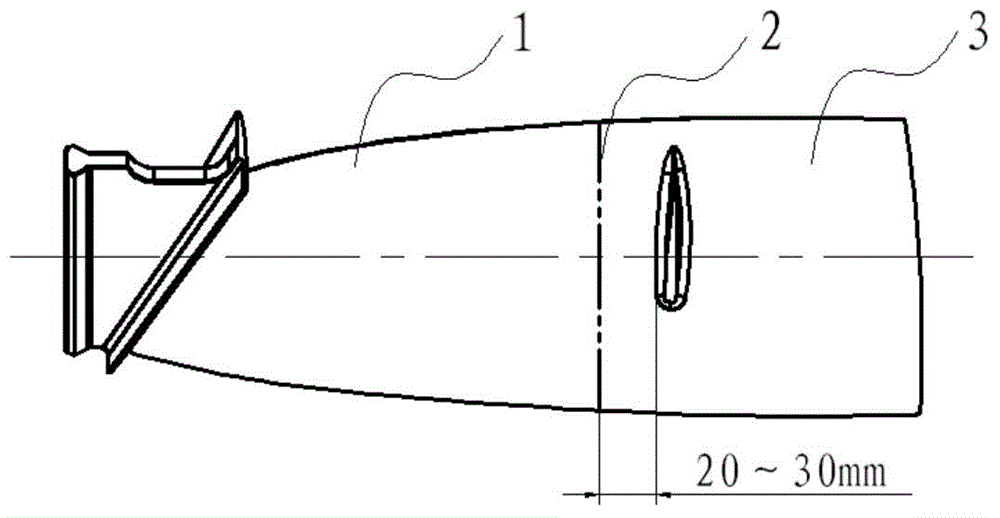

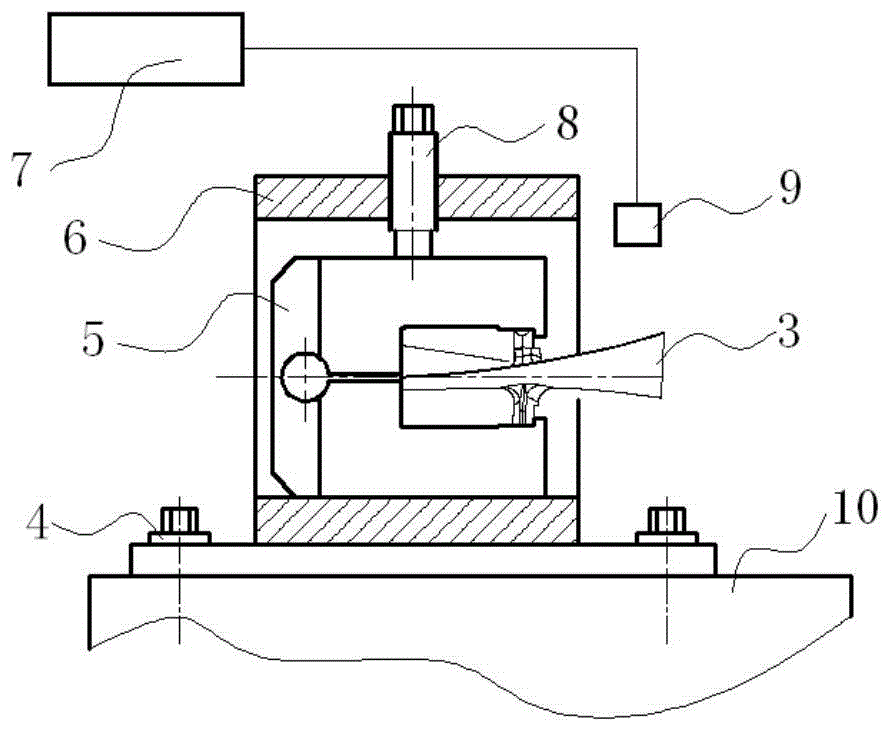

[0036] like figure 1 , 2 , 3a, and 3b, the fatigue strength test method of a fan blade with shoulders for a certain large bypass ratio engine: pass the upper half 3 or lower half 1 of the blade with the shoulder through the fixture with a special clamp 5 or 11 The device (including fixture base 6, connecting bolt 4, and compression screw 8) is fixed on the vibrating table 10, and the blade body is suspended in the air. The laser displacement sensor 9 and the test instrument 7 form a measurement system, which is excited by the vibration table 10 to make the airfoil body suspended in the air. Vibration is generated to complete the fatigue strength test. Test its steps:

[0037] (1) Cutting and cutting test blades: according to the purpose of the test, first cut the blades with shoulders in the direction of blade height, at about 20-30 mm below the shoulders, and divide them into upper half blades and lower half blades, see figure 1 Instructions indicate.

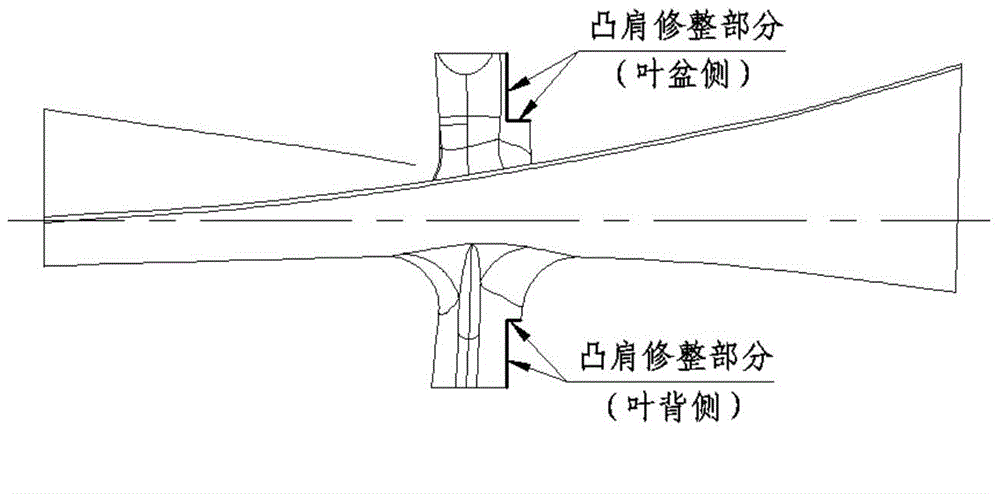

[0038] (2) Shoulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com