Device and method for detecting high-temperature vibration fatigue characteristics of aero-engine blade

An aero-engine and vibration-fatigue technology, which is used in measurement devices, vibration testing, and testing of mechanical components. Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

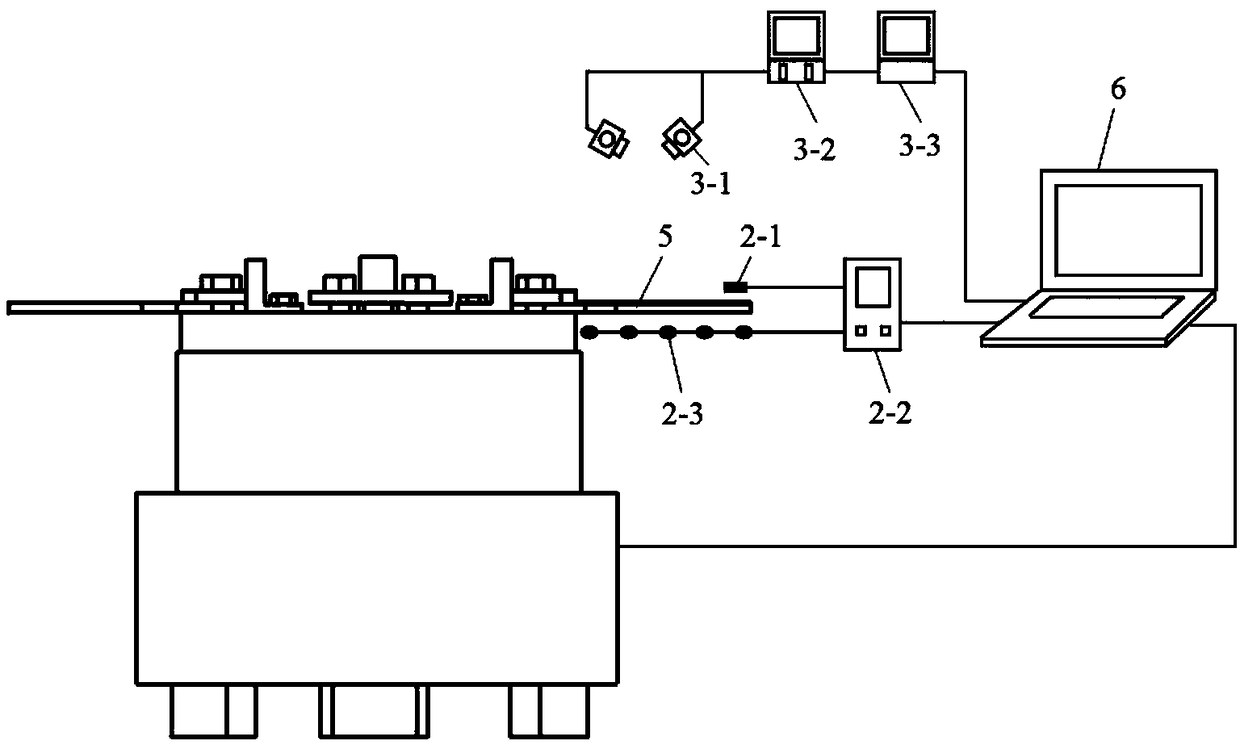

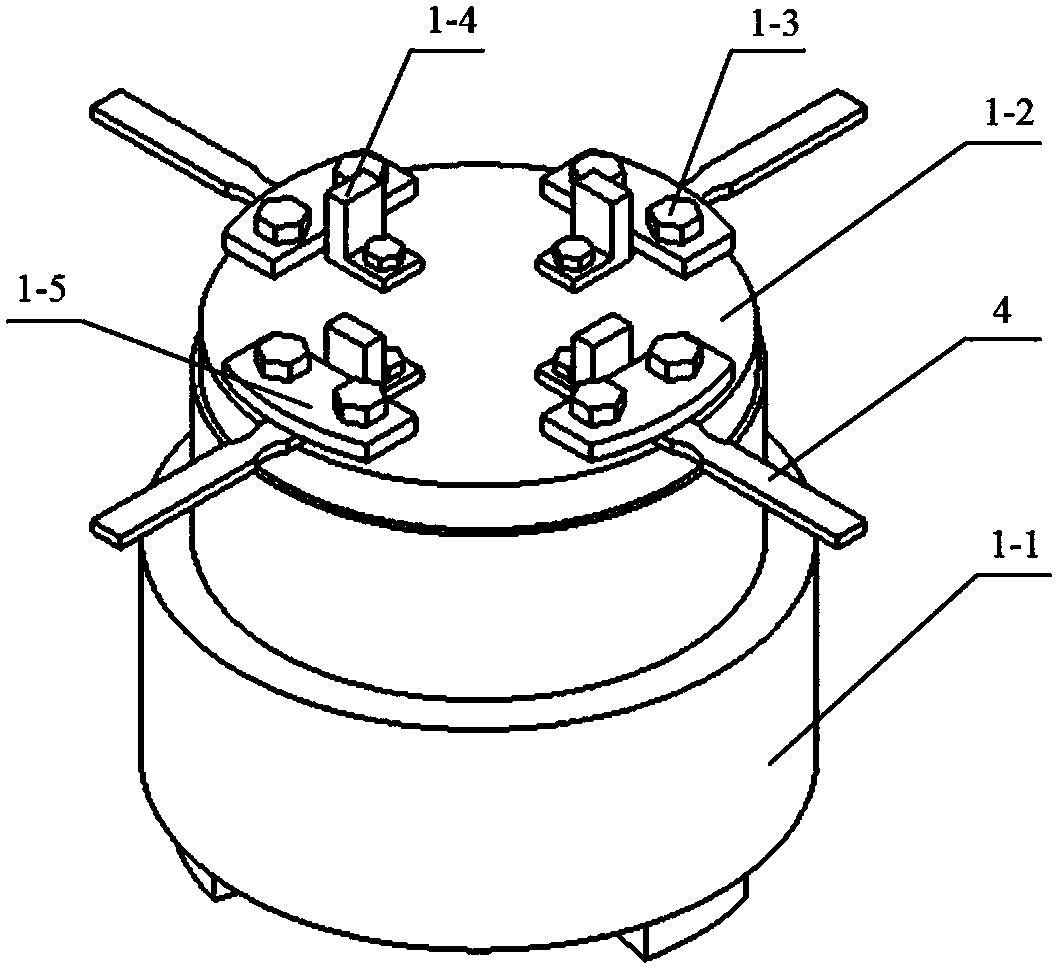

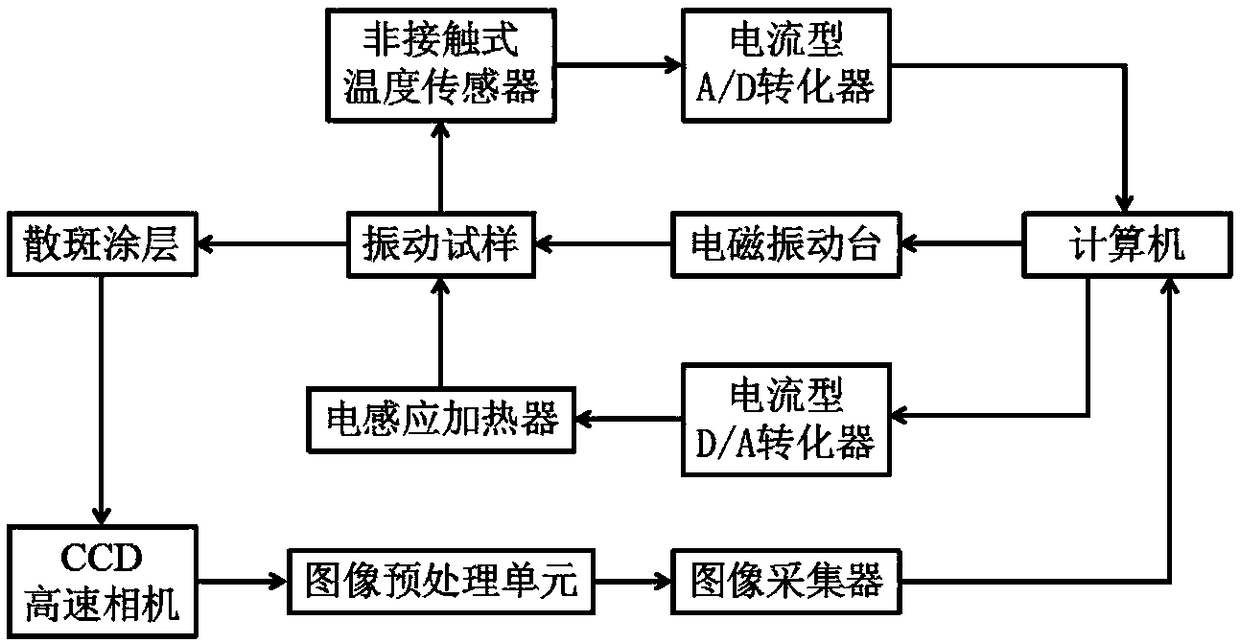

[0046] Such as figure 1 As shown, the detection device for detecting high-temperature vibration fatigue characteristics of aeroengine blades according to the present invention includes a vibration loading system, an electric induction heating system, a digital image acquisition system, and a computer. Such as figure 2 As shown, the vibration loading system includes an electromagnetic vibration table 1-1, a heat insulation washer 1-2, a bolt 1-3, a positioning block 1-4, a high temperature fixture 1-5, and the heat insulation washer 1-2 is fixed by bolt connection On the vibrating table, the positioning block 1-4 is connected and fixed on the heat insulating washer 1-2 through the bolt 1-3. A thermal insulation gasket 1-2 is set between the positioning block 1-4, the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com