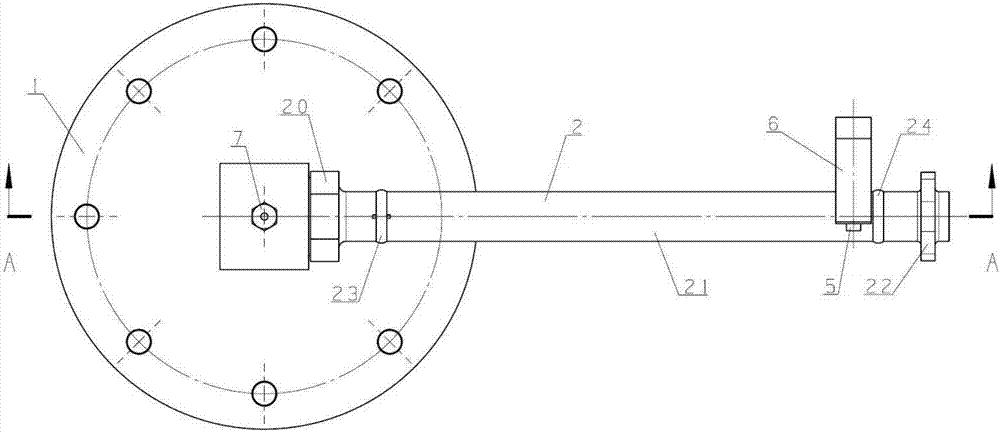

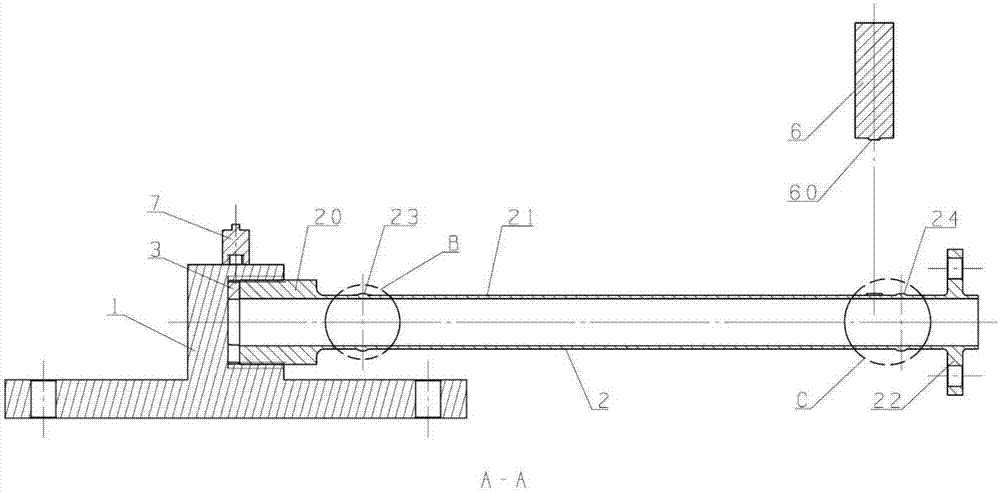

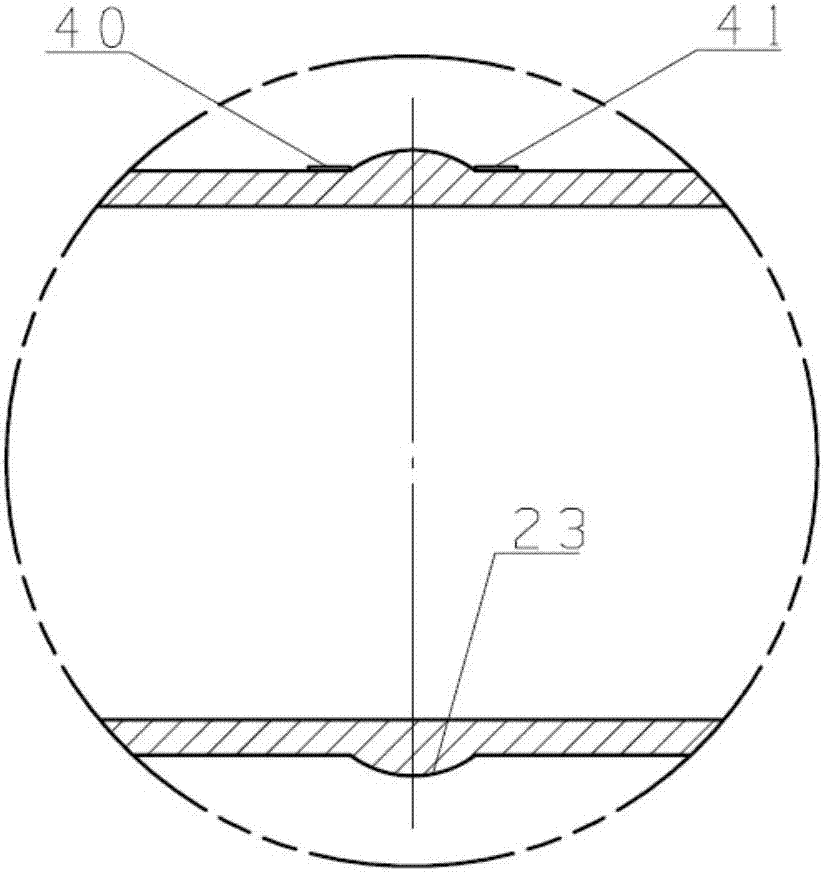

Test apparatus, system and method for obtaining vibration fatigue limit of welded pipe

A test device and vibration fatigue technology, which is applied in the field of test devices for obtaining the vibration fatigue limit of welding pipelines, can solve problems such as pipeline fatigue cracks, threats to the safety of aeroengines, pipeline oil leakage and air leakage, etc., to achieve accurate acquisition, fatigue The test method is correct and feasible, and the system is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

[0049] Fatigue life is the number of stress cycles experienced by a structure before fatigue cracks develop at a specified stress level. In general, the fatigue life of a component is determined by its fatigue test. Under linear elastic conditions, it is usually determined by the stress-fatigue curve (S-N curve) of the material or part. The stress fatigue curve is based on the stress amplitude S and the corresponding failure cycle number N L The curve made between the measured data. However, in general, the S-N curve is obtained through fatigue tests, which is long-term and expensive. From the perspective of engineering applications, an empirical formula for the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com