Vibratory fatigue testing method of aviation-engine blades based on electrodynamics vibration generator

An electric vibration table and aero-engine technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as high vibration frequency of blades, drift of vibration response amplitude, loss of monitoring of tests, etc., to achieve guaranteed testing Accuracy, Effect of Stabilizing Vibration Stress Levels

Inactive Publication Date: 2015-07-01

TIANJIN AEROSPACE RELIA TECH +2

View PDF5 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This is often accompanied by the following problems: due to the small-scale drift (0-2Hz) of the resonant frequency of the blade, the amplitude of the vibration response also drifts, making the stress at the point of the maximum response stress of the blade unstable, and there are often overtests or undertests. The test results have a great impact; a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

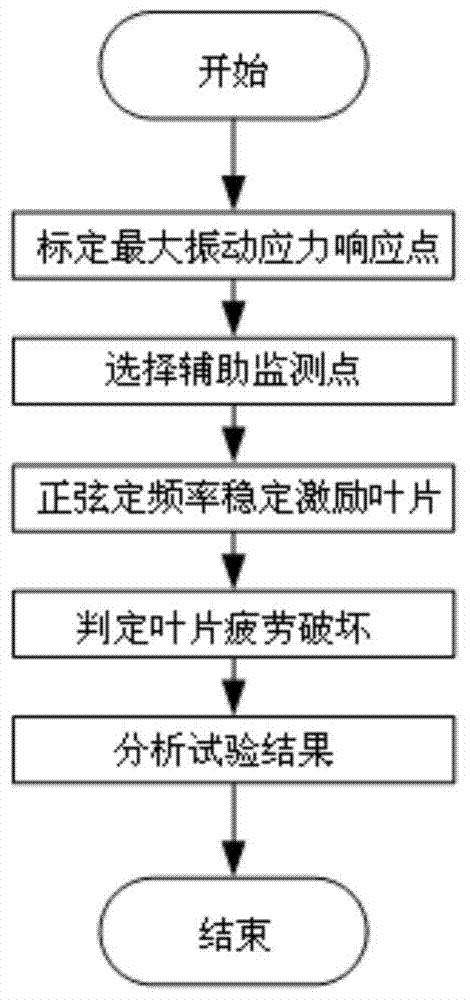

The invention belongs to the technical field of testing of vibratory fatigue and in particular relates to a vibratory fatigue testing method of aviation-engine blades based on an electrodynamics vibration generator; the method aims at solving over-testing or insufficient testing problem in the prior art and comprises the steps: calibrating a maximum vibratory stress response point, choosing auxiliary monitoring points, choosing sine constant-frequency stabilization and simulation blades, judging the fatigue destruction of the blades and analyzing testing results. By adopting the steps of choosing the auxiliary monitoring points and choosing the sine constant-frequency stabilization and simulation blades, the vibratory stress level (the fluctuation error is within 2%) of the blades in the testing process is stabilized effectively, the testing precision is guaranteed and the full-process monitoring of the vibratory stress level of the blades at the maximum stress point is realized.

Description

technical field [0001] The invention belongs to the technical field of vibration fatigue tests, in particular to an aeroengine blade vibration fatigue test method based on an electrodynamic vibration table. Background technique [0002] The aero-engine is regarded as the "heart" of a fighter plane, and the engine blade is the part with the worst working environment and the most complex structure of the aero-engine, and it is also the main failure-prone part of the engine. The reliability of aeroengine blades restricts the requirements of high thrust-to-weight ratio, high applicability, high reliability, durability and low cost of modern high-performance aeroengines. [0003] During the working process, the blades of aero-engines will bear heavy alternating loads for a long time. When the magnitude of the alternating load exceeds the corresponding fatigue limit, fatigue cracks will appear on the blade within the design life, and gradually develop to fatigue fracture, and eng...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M7/02

Inventor 陈立伟陈永祥杨博何胜帅徐海博孙立明赵帅帅贾业宁彭康

Owner TIANJIN AEROSPACE RELIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com