Evaluation method for reliable life of blade vibration fatigue of gas compressor impeller of supercharger

An impeller blade and vibration fatigue technology is applied in the field of structural reliability and life evaluation of the compressor impeller of a turbocharger for vehicles. problems, to achieve the effect of good structural design and rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

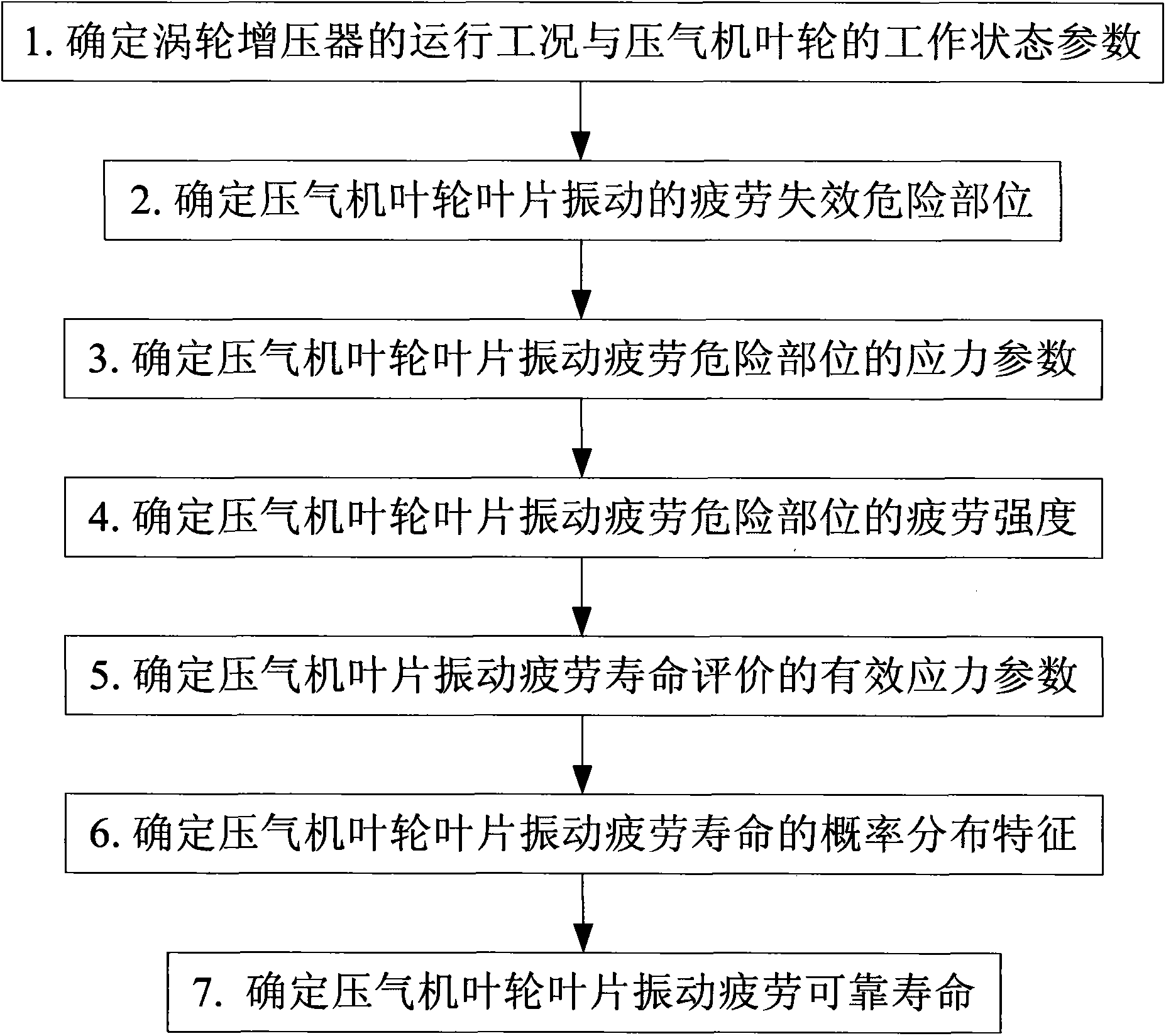

[0039] A vehicle turbocharger compressor impeller vane vibration fatigue reliability life evaluation method, comprising the following steps:

[0040] a. Determine the operating conditions of the vehicle turbocharger and the working state parameters of the compressor impeller: combined with the task profile of the vehicle engine, use the simulation calculation method or pass the test test according to the matching relationship between the turbocharger and the engine to determine the The operating conditions of the turbocharger and its composition and the corresponding operating time under different operating conditions; then, according to the operating conditions of the turbocharger, use simulation calculation or test methods to determine the compressor impeller under different operating conditions Working state parameters during operation, namely compressor impeller speed, inlet temperature, outlet temperature, inlet pressure, outlet pressure and flow;

[0041]For example, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com