Method for deducing stress intensity factor of butt joint containing I-type center bursts and application

A technology of stress intensity factor and butt joint, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems that the formula of stress intensity factor is not given, and the structural design of butt joint cannot be guided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

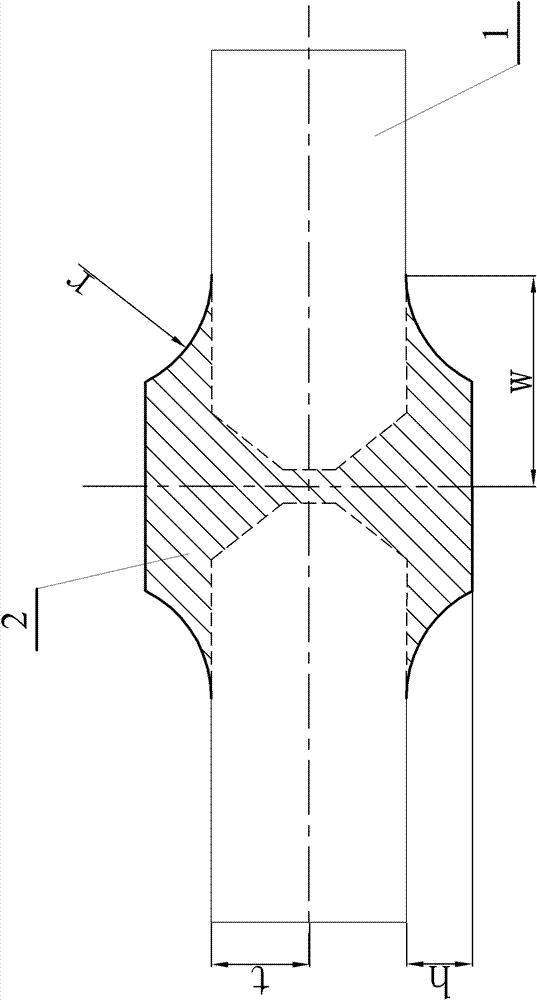

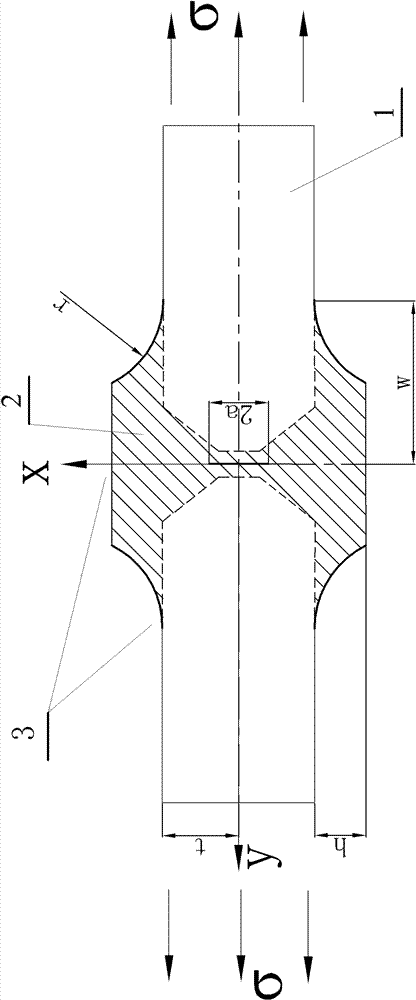

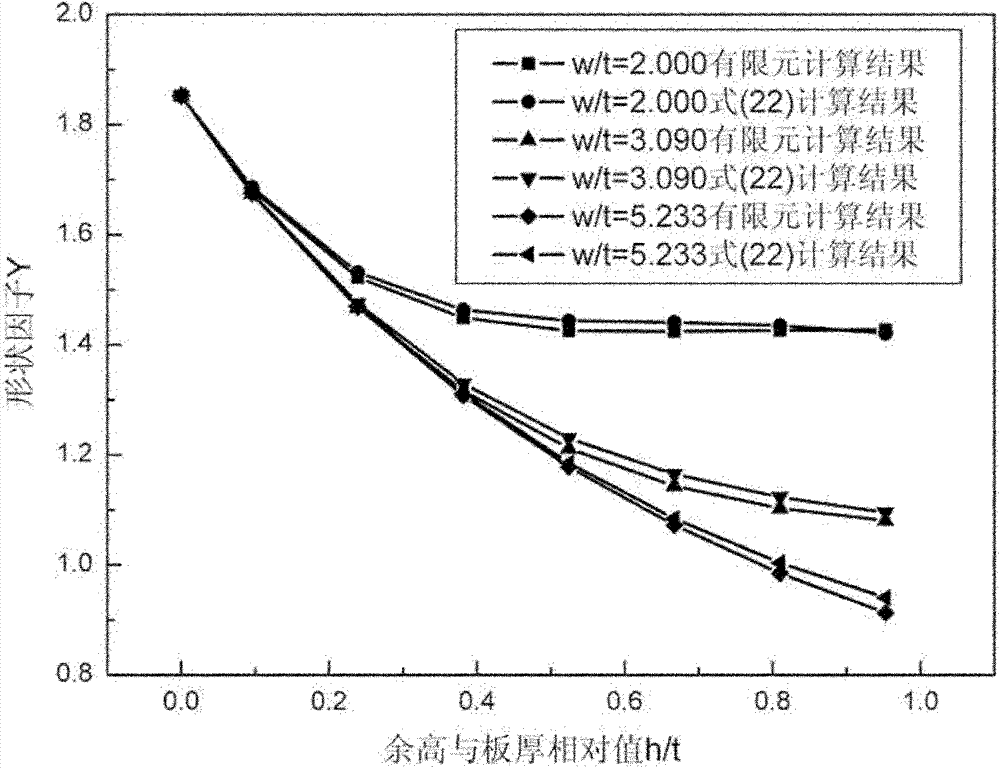

[0101] Specific implementation mode one: as Figure 1~3 As shown, the specific process of the derivation method of the stress intensity factor of the butt joint with type I central crack described in this embodiment is:

[0102] Step 1. Analytical calculation The stress intensity factor formula when only the weld reinforcement h is considered:

[0103] Based on the case of joints with reinforcements containing central cracks (if attached figure 2 shown), it can be seen from any fracture mechanics textbook that for an infinite plate with a central penetrating crack subjected to uniform tensile stress, the Westcrgacrd stress function of the problem is:

[0104] Z I ( z ) = σz z 2 - a 2 - - - ( ...

specific Embodiment approach 2

[0137] Specific implementation mode two: as Figure 1~3 As shown, in this embodiment, the stress intensity factor formula of a butt joint with a type I central crack is used to determine half of the critical crack size of a butt joint with a type I central penetrating crack with a certain reinforcement c ;

[0138] Specific steps are as follows:

[0139] Step 1. Measure the fracture toughness K of the weld material ⅠC ;

[0140] Step 2. Substituting the shape parameters of the joint: the half-width of the capping weld bead w, the weld reinforcement h, the arc transition radius r of the weld toe, and half of the plate thickness t into formula (13) to obtain f;

[0141] Step 3: Establish and calculate half of the critical crack size a of the butt joint with a type I central penetrating crack with a certain reinforcement height c The formula for:

[0142] a c = ( ...

specific Embodiment approach 3

[0145] Specific implementation mode three: as Figure 1~3 As shown, in this embodiment, the critical load σ of the butt joint with a type I central penetrating crack and a certain reinforcement is determined by using the stress intensity factor formula of the butt joint with a type I central penetrating crack and a certain reinforcement c ;

[0146] Specific steps are as follows:

[0147] Step 1. Establish and calculate the critical load σ of the butt joint with a certain reinforcement height of the type I central penetrating crack c The formula for:

[0148] σ c = K IC { 1 + ( 0.85038 + 0.84549 h h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com