A Cylinder Head Reliability Life Evaluation Method

An evaluation method and cylinder head technology, applied in the direction of instrumentation, geometric CAD, design optimization/simulation, etc., can solve the problems of complex cylinder head geometry, large cylinder head failure forms with large dispersion of casting performance, etc., and achieve good structural design and rationality. Use and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0051] The present invention will be described in detail below with reference to the accompanying drawings and examples.

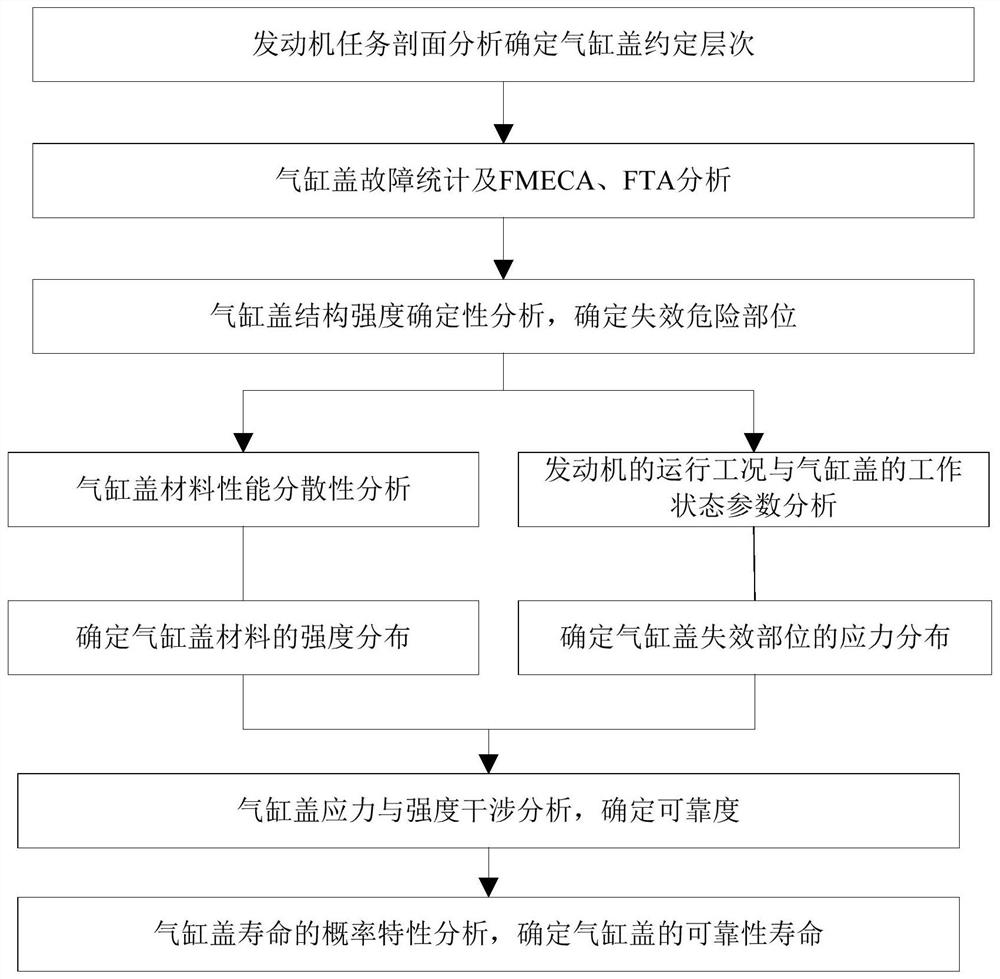

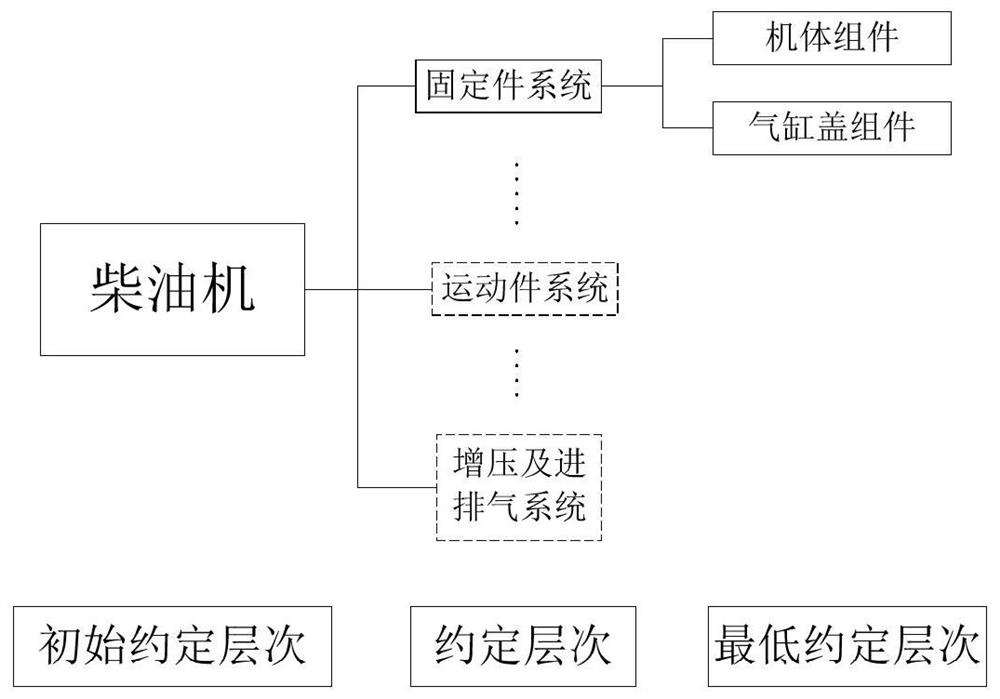

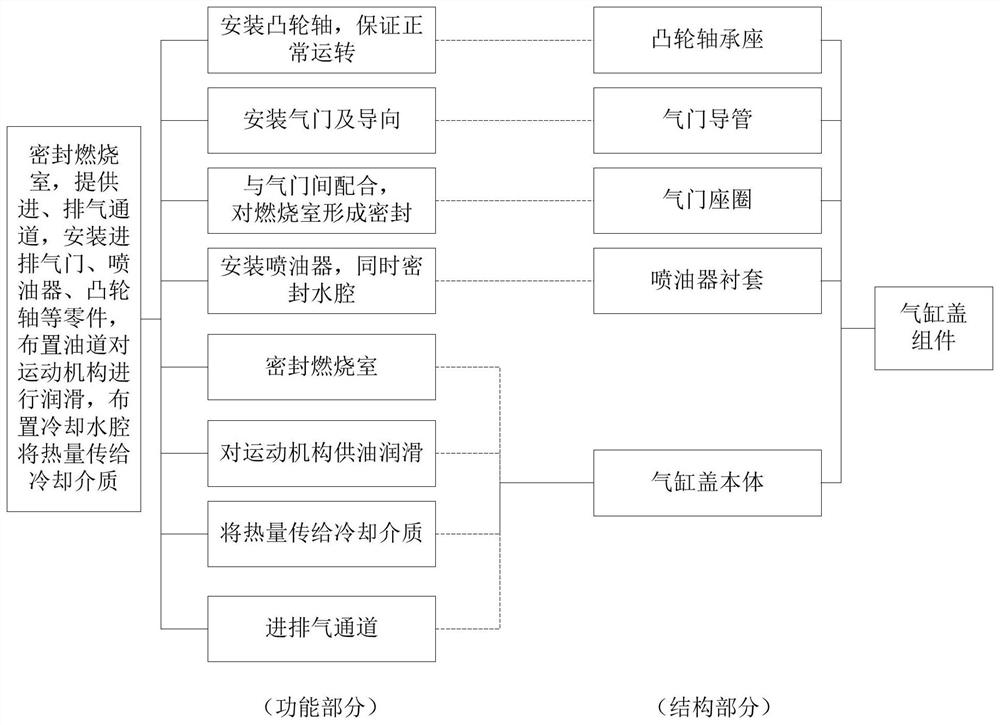

[0052] A method for evaluating the reliability life of a cylinder head of a vehicle engine, comprising the following steps:

[0053] a. According to the purpose and actual use of the engine, determine the task profile of the engine, and define the running time and state parameters of the engine under different working conditions.

[0054] For example, in the trial production research stage of an engine, the durability bench test is used as a task profile: the cycle time of the bench durability assessment test is 10 hours, and the key consideration for the cylinder head life estimation is 100% of the calibrated speed for 1 hour , 85% to 90% of the calibrated speed for 7 hours, 80% of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com