Lithium ion battery and anode material thereof

A lithium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not being able to improve the high-temperature storage performance of the battery, and not being able to obtain battery performance, and achieve excellent electrochemical performance, excellent cycle performance, The effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

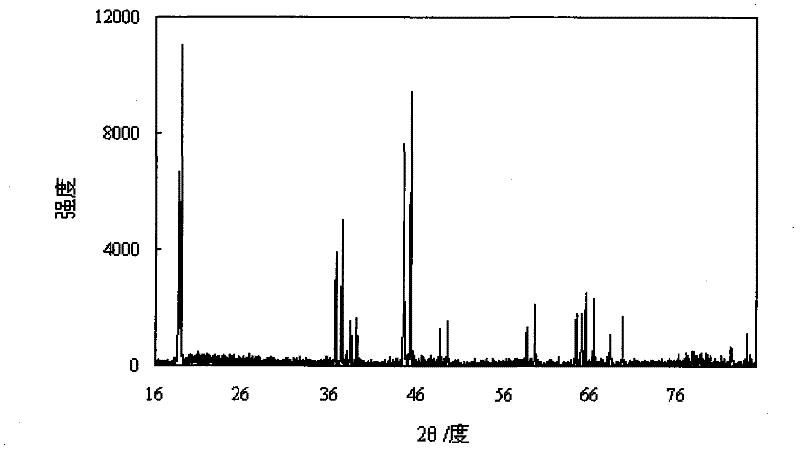

[0042] 0.475g isopropyl titanate (Ti[OCH(CH 3 ) 2 ] 4 ) and 0.378g aluminum isopropoxide (C 9 h 21 AlO 3 ) was added to 200mL of absolute ethanol, stirred to make it evenly mixed, and then 60g of LiCoO 2 and 40g Li(Ni 0.5 co 0.2 mn 0.3 )O 2 The homogeneous mixture was added therein, and after stirring for 2 hours, the above-mentioned liquid was separated into solid and liquid, and the obtained solid was vacuum-dried at 120°C, and then tempered in air at 600°C for 3 hours to obtain the positive electrode material of the present invention. The XRD spectrum of above-mentioned composite cathode material is as follows figure 1 shown.

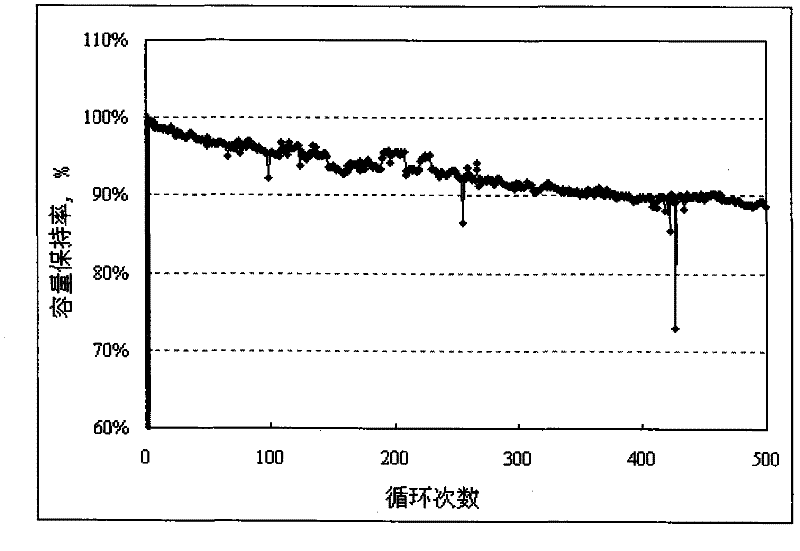

[0043] The first-time reversible capacity of the above-mentioned composite positive electrode material measured in the button battery is 150.8mAh / g, and the first-time efficiency is 90.3%. The capacity retention rate of the above positive electrode material after 500 cycles in 454261 pouch battery is 88.6%. The cycle curve is as follows: ...

Embodiment 2

[0045] 0.178g isopropyl titanate (Ti[OCH(CH 3 ) 2 ] 4 ) and 0.606g aluminum isopropoxide (C 9 h 21 AlO 3 ) was added to 200mL of absolute ethanol, stirred to make it evenly mixed, and then 60g of LiCoO 2 and 40g Li(Ni 0.8 co 0.1 mn 0.1 )O 2 The homogeneous mixture was added therein, and after stirring for 2 hours, the above-mentioned liquid was separated into solid and liquid, and the obtained solid was vacuum-dried at 120°C, and then tempered in air at 600°C for 3 hours to obtain the positive electrode material of the present invention.

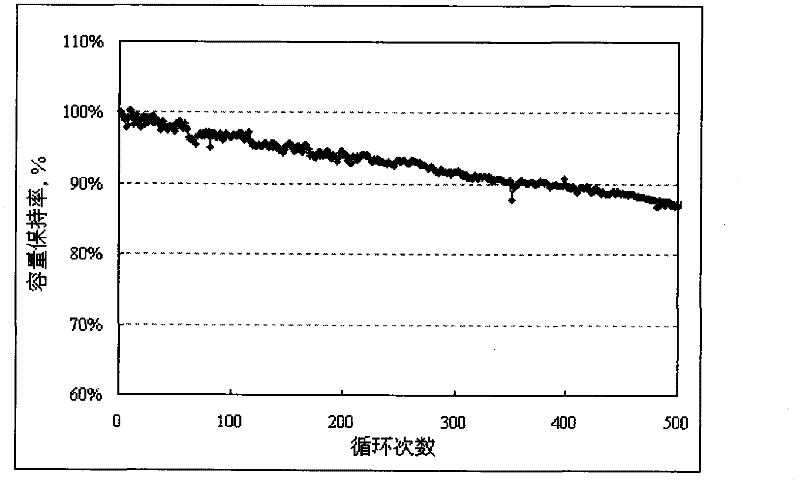

[0046] The first reversible capacity of the above-mentioned composite cathode material measured in a button battery is 158.9mAh / g, and the first efficiency is 89.4%. The capacity retention rate of the above positive electrode material after 500 cycles in 454261 pouch battery is 86.7%. The cycle curve is as follows: image 3 As shown, the 85°C / 4h high-temperature storage thickness expansion rate is 10%, and the 85°C / 4h high-temperat...

Embodiment 3

[0048] 1.112g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) and 0.031g lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) added to 200mL deionized water, stirred to make it evenly mixed, and then 60g LiCoO 2 and 40g Li(Ni 0.8 co 0.1 mn 0.1 )O 2 The homogeneous mixture was added therein, and after stirring for 2 hours, the above-mentioned liquid was separated into solid and liquid, and the obtained solid was vacuum-dried at 120°C, and then tempered in air at 600°C for 3 hours to obtain the positive electrode material of the present invention.

[0049] The first-time reversible capacity of the above-mentioned composite cathode material measured in a button battery is 159.2mAh / g, and the first-time efficiency is 89.5%. The capacity retention rate of the above positive electrode material after 500 cycles in 454261 pouch battery is 81.3%. The cycle curve is as follows: Figure 4 As shown, the 85°C / 4h high-temperature storage thickness expansion rate is 36%, and the 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com