All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low durability and cycle performance, low battery output power, etc., to achieve good durability and cycle stability, high Output power, effect of suppressing formation of space charge layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

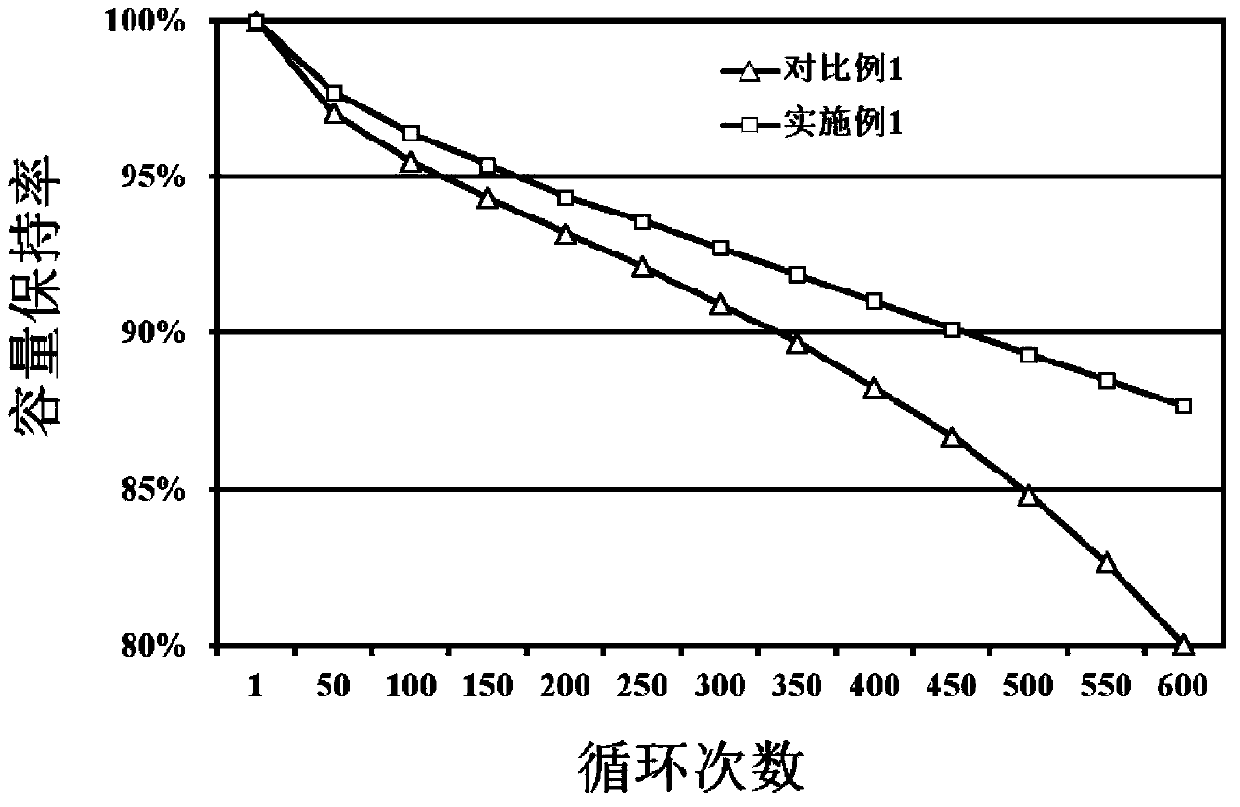

Examples

preparation example Construction

[0039] In the second aspect, the embodiment of the present invention provides a method for preparing the composite positive electrode material of the above-mentioned all-solid-state lithium ion battery, including: placing the positive electrode active material on the substrate as the substrate, the material of the cladding layer as the target material, and placing In the radio frequency magnetron sputtering equipment, a coating layer is prepared on the surface of the positive electrode active material by radio frequency magnetron sputtering to obtain an all-solid lithium ion battery composite positive electrode material with a coating layer, wherein the positive electrode The active material is one or more of lithium cobalt oxide, lithium nickel oxide, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese oxide, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer The material is lithium titanate Li 4 TiO 4 , lithium vana...

Embodiment 1

[0063] A kind of preparation method of all-solid-state lithium-ion battery composite cathode material

[0064] The positive electrode active material lithium cobalt oxide (LiCoO 2 ) placed on the substrate as a substrate, lithium titanate (Li 4 TiO 4 ) as a target, placed in the radio frequency magnetron sputtering equipment, by the method of radio frequency magnetron sputtering in the positive electrode active material lithium cobaltate (LiCoO 2 ) surface deposition to prepare a layer of lithium titanate (Li 4 TiO 4 ), and finally the surface is coated with lithium titanate (Li 4 TiO 4 ) of lithium cobalt oxide (LiCoO 2 ) Composite cathode material for all-solid-state lithium-ion batteries, denoted as A1. In this example, lithium titanate (Li 4 TiO 4 ) in lithium cobalt oxide (LiCoO 2 ) surface with a thickness of 20nm.

[0065] In radio frequency magnetron sputtering, argon is used as the sputtering gas, the internal pressure of the radio frequency magnetron sputt...

Embodiment 2

[0071] A kind of preparation method of all-solid-state lithium-ion battery composite cathode material

[0072] The positive electrode active material lithium manganese oxide (LiMnO 2 ) placed on the substrate as a substrate, lithium zirconate (Li 4 ZrO 4 ) as a target, placed in the radio frequency magnetron sputtering equipment, by the method of radio frequency magnetron sputtering in the positive electrode active material lithium manganese oxide (LiMnO 2 ) surface deposition to prepare a layer of lithium zirconate (Li 4 ZrO 4 ), and finally the surface is coated with lithium zirconate (Li 4 ZrO 4 ) Lithium manganese oxide (LiMnO 2 ) Composite cathode material for all-solid-state lithium-ion batteries, denoted as A2. In this example, lithium zirconate (Li 4 ZrO 4 ) in lithium manganese oxide (LiMnO2 ) surface with a thickness of 0.1 nm.

[0073] In radio frequency magnetron sputtering, argon is used as the sputtering gas, the internal pressure of the device cavity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com