Carbon-coated hollow ferriferrous oxide and application thereof

A technology of ferroferric oxide and carbon coating, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of unsuitability for industrial production, long synthesis cycle, and high production cost, so as to buffer internal stress, improve electrical conductivity, Effect of High Capacity Retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

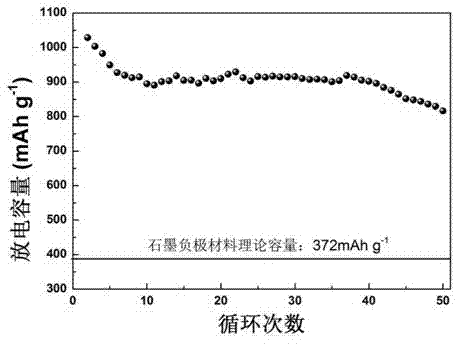

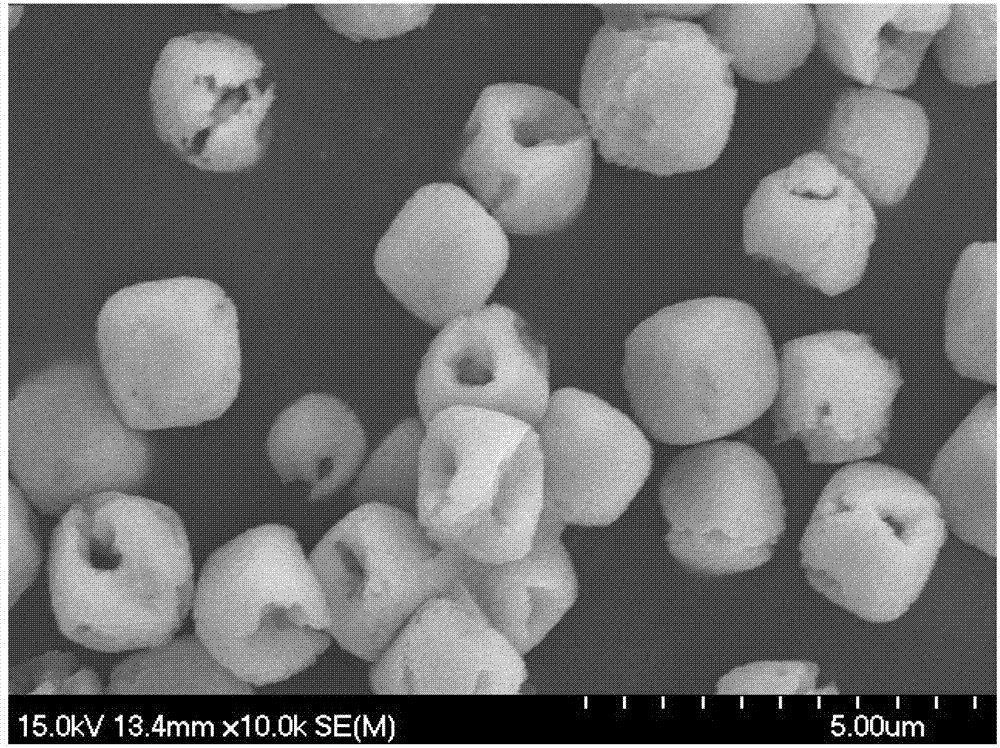

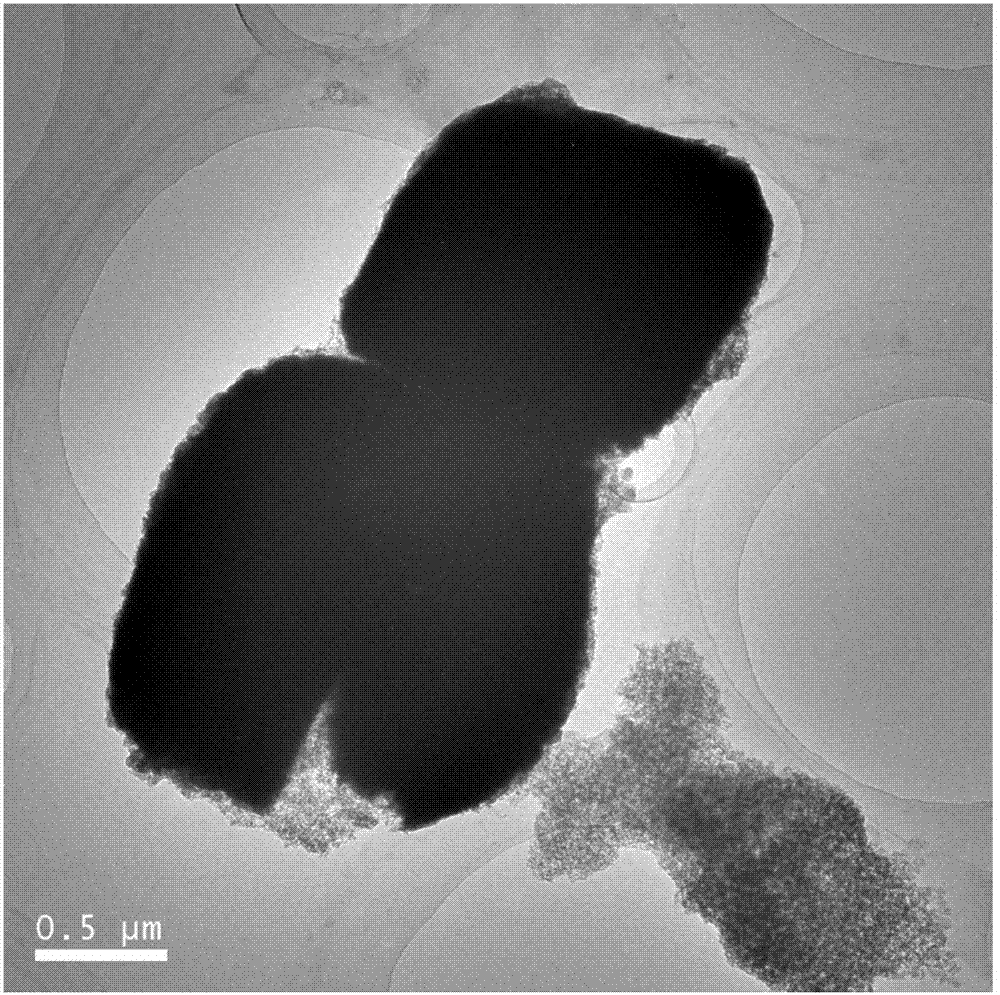

[0026] First, dissolve 0.4 g of ferric chloride in a mixed solvent of 18 ml of water and 22 ml of ethanol. After stirring and dissolving, put it into a closed hydrothermal kettle and place it in an oven at 180° C. for 20 hours to keep it warm. After the reaction, the iron oxide precipitate in the hydrothermal kettle was filtered, washed and dried. 0.5 g of glucose was added to the iron oxide powder and mixed evenly, and then placed in a muffle furnace at 300° C. for 3 hours to obtain the final product. It is a carbon-coated ferric oxide with uniform particles (see figure 1 ).

[0027] Weigh carbon-coated hollow iron ferric oxide: acetylene black: polyvinylidene fluoride at a mass ratio of 70:20:10, grind them evenly, and coat them on copper foil to make electrodes. Metal lithium sheets are used as positive electrodes. The electrolyte is 1 mol / L LiPF 6 / EC-DMC (volume ratio 1:1), polypropylene microporous film as a separator (Celgard 2300), assembled into a button battery (...

Embodiment 2

[0029] First, dissolve 0.5 g of ferric chloride in a mixed solvent of 20 ml of water and 20 ml of ethanol. After stirring and dissolving, put it into a closed hydrothermal kettle and place it in an oven at 170°C for 24 hours to keep it warm. After the reaction, the iron oxide precipitate in the hydrothermal kettle was filtered, washed and dried. 0.6 g of glucose was added to the iron oxide powder and mixed evenly, and then placed in a muffle furnace at 350° C. for 4 hours to obtain the final product. Product appearance is similar to figure 1 .

[0030] The obtained carbon-coated hollow Fe3O4 material was used to prepare electrodes according to the method in Example 1, and assembled into a simulated battery. At a current density of 0.1 A / g, its reversible capacity reached 830 mAh / g.

Embodiment 3

[0032] First, dissolve 0.4 g of ferric chloride in a mixed solvent of 16 ml of water and 24 ml of ethanol. After stirring and dissolving, put it into a closed hydrothermal kettle and place it in an oven at 190°C for 26 hours. After the reaction, the iron oxide precipitate in the hydrothermal kettle was filtered, washed and dried. 0.8 g of glucose was added to the iron oxide powder and mixed uniformly, and then placed in a muffle furnace at 350° C. for 2 hours to obtain the final product. Product appearance is similar to figure 1 .

[0033] The obtained carbon-coated hollow Fe3O4 material was used to prepare electrodes according to the method in Example 1, and assembled into a simulated battery. At a current density of 0.1 A / g, its reversible capacity reached 810 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com