Method for preparation of composite material containing silicon

A technology of silicon composite materials and composite particles, which is applied in electrode manufacturing, structural parts, electrical components, etc., can solve the problems of low specific capacity and poor cycle performance of batteries, and achieve the effect of high specific capacity and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

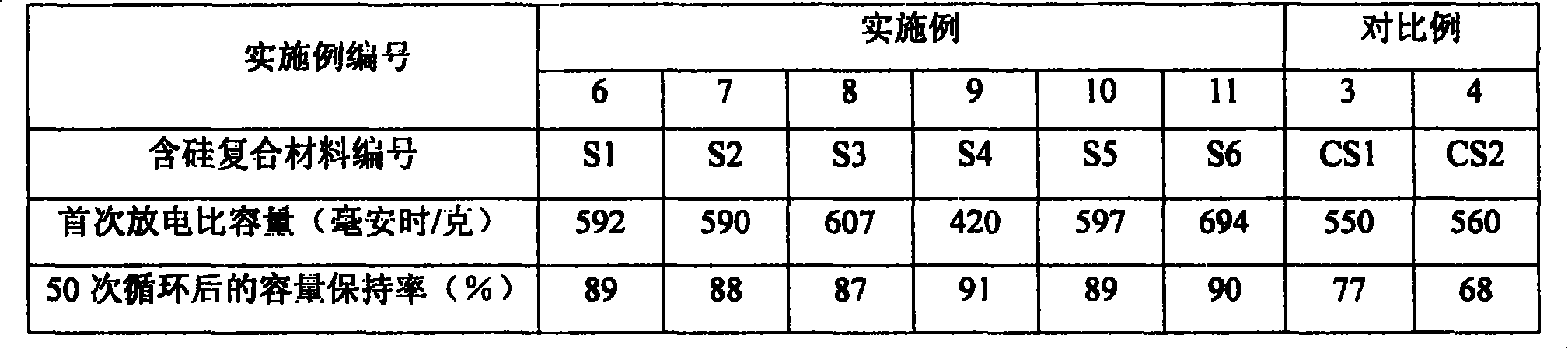

Examples

preparation example Construction

[0017] According to the preparation method of the silicon-containing composite material provided by the present invention, the composite material particles containing elemental silicon, graphite and surfactant can be obtained by uniformly dispersing elemental silicon particles, graphite particles and carbon nanotubes in a solution containing surfactant Remove the solvent to get. Described tensio-active agent can be conventional various macromolecule surfactants, for example can be polyvinyl alcohol, polyvinylpyrrolidone, polyethylene glycol, polyacrylic acid, polytetrafluoroethylene, polyvinylidene fluoride, carboxymethyl fiber One or more of cellulose, carboxyethyl cellulose, carboxymethyl methyl cellulose, polyacrylamide. After removing the solvent, the above-mentioned polymeric surfactant can coat elemental silicon, graphite and carbon nanotube particles to obtain composite material particles containing elemental silicon, graphite and carbon nanotubes. Because polyvinyl al...

Embodiment 1

[0028] This example is used to illustrate the silicon-containing composite material provided by the present invention and its preparation method.

[0029] Add 60 milliliters of deionized water, 15 milliliters of ethanol and 2 grams of polyvinyl alcohol into a 100 milliliter beaker, after stirring for 30 minutes, slowly add 10 grams of natural graphite (average particle diameter D 50 = 18 microns, crystallite layer spacing d 002 0.335 nanometers), after continuing to stir for 30 minutes, add 1 gram of nano silicon (particle diameter is 20-50 nanometers) and 0.06 gram carbon nanotubes (particle diameter is 20-50 nanometers, length 1- 2 microns), continue to stir and filter after 40 minutes, join the solution that contains 1.5 grams of epoxy resin E-44 and 40 milliliters of ethanol after the solid vacuum drying that obtains, stir in advance, continue to stir and filter after 40 minutes, The resulting solid was dried. Dry the solid in N 2 Under protection, the temperature was r...

Embodiment 2

[0037] This example is used to illustrate the silicon-containing composite material provided by the present invention and its preparation method.

[0038] Add 60 milliliters of deionized water, 15 milliliters of ethanol and 2 grams of polyvinylpyrrolidone into a 100 milliliter beaker, after stirring for 25 minutes, slowly add 10 grams of natural graphite (average particle diameter D 50 = 20 microns, crystallite layer spacing d 002 0.335 nanometers), after continuing to stir for 30 minutes, add 1 gram of nano silicon (particle diameter is 20-50 nanometers) and 0.17 grams of carbon nanotubes (particle diameter is 20-50 nanometers, length 0.5- 1 micron), continue to stir for 40 minutes and then filter, then add the solid obtained after vacuum drying to a solution that has been stirred uniformly beforehand containing 1.5 grams of epoxy resin E-50 and 40 milliliters of ethanol, continue to stir for 40 minutes and then filter, The resulting solid was dried. Dry the solid in N 2 U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com